X 60 pipeline steel with thickness of 16-25 mm and production method of pipeline steel

A production method and pipeline steel technology, which is applied in the field of pipeline steel production, can solve the problems of general material deformation ability, small shaping range, and few adopters, so as to reduce the Bauschinger effect, improve the purity of molten steel, and reduce the Bauschinger effect. low grid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

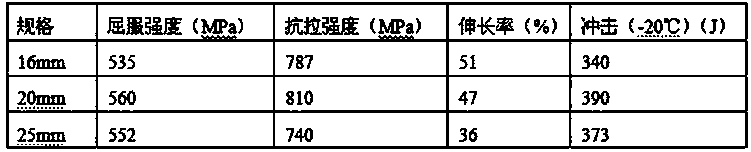

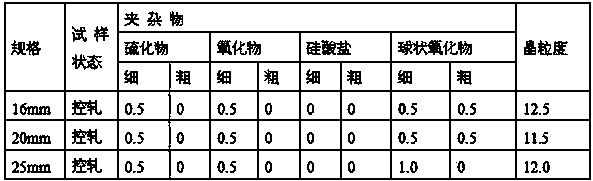

Embodiment 1

[0029] In this embodiment, the production of 16mm thick X60 pipeline steel is taken as an example, and the above-mentioned specific production method is adopted for production. The rolling temperature is 950°C; the final rolling temperature in the first stage is 975°C, the starting rolling temperature in the second stage is 880°C, and the second stage adopts small reduction rolling to ensure the original plate shape, and the final rolling temperature is 800°C; the steel plate is rolled into ACC for Rapid cooling, the water inlet temperature is 760°C, the red return temperature is 480°C, and the cooling rate is controlled at 16°C / s.

Embodiment 2

[0031] In this embodiment, the production of 20mm thick X60 pipeline steel is taken as an example, and the above-mentioned specific production method is adopted for production. The rolling temperature is 1100°C; the final rolling temperature in the first stage is 975°C, the starting rolling temperature in the second stage is 900°C, the second stage adopts rolling under small reduction to ensure the original plate shape, and the final rolling temperature is 830°C; the steel plate is rolled into ACC for Rapid cooling, the water inlet temperature is 775°C, the redness temperature is 490°C, and the cooling rate is controlled at 17°C / s.

Embodiment 3

[0033] In this embodiment, the production of 25mm thick X60 pipeline steel is taken as an example, and the above-mentioned specific production method is adopted for production. The rolling temperature is 1150°C; the final rolling temperature in the first stage is 1000°C, the starting rolling temperature in the second stage is 920°C, and the second stage is rolled under a small reduction to ensure the original plate shape, and the final rolling temperature is 860°C; the steel plate is rolled into ACC for Rapid cooling, the water inlet temperature is 790°C, the red return temperature is 520°C, and the cooling rate is controlled at 18°C / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com