Method for controlling non-quenched and tempered high-intensity screw bolt steel high Bauschinger effect

A technology of Bauschinger effect and high-strength bolts is applied in the field of deep processing and drawing technology control, which can solve the problems of easy cracking of heading heads and high loss of grinding tools of heading heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention is at a height of 160mm 2 It has been applied in the production of Φ6.5mm wire rod, and non-quenched and tempered steel with excellent performance has been obtained.

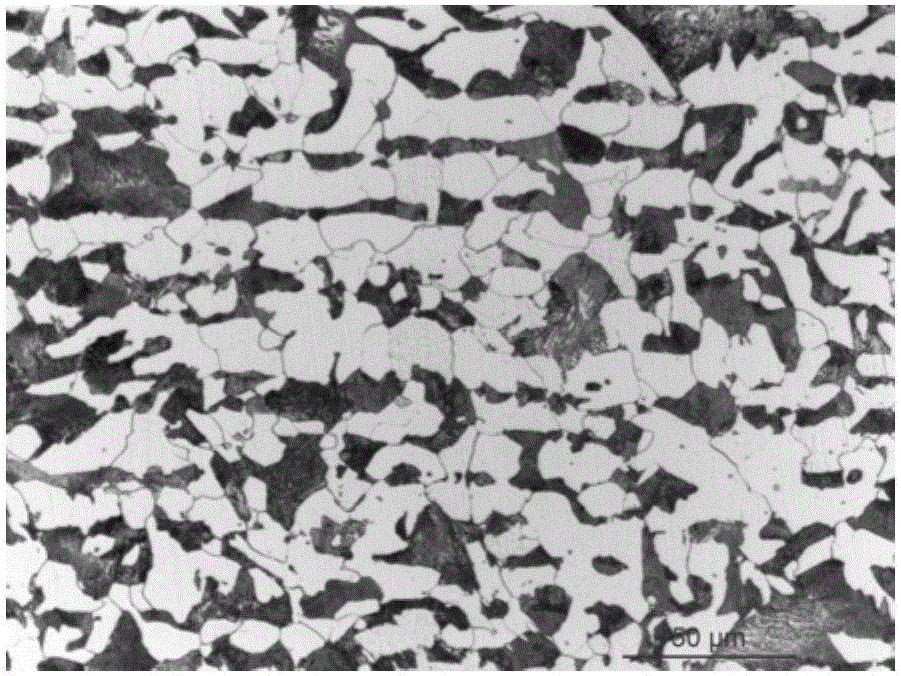

[0021] 1 Stelmo air-cooling control, cover the insulation cover 5-22#, control the slow cooling cooling rate 1°C / s, and obtain the ferrite content in the tissue to be 50-55%;

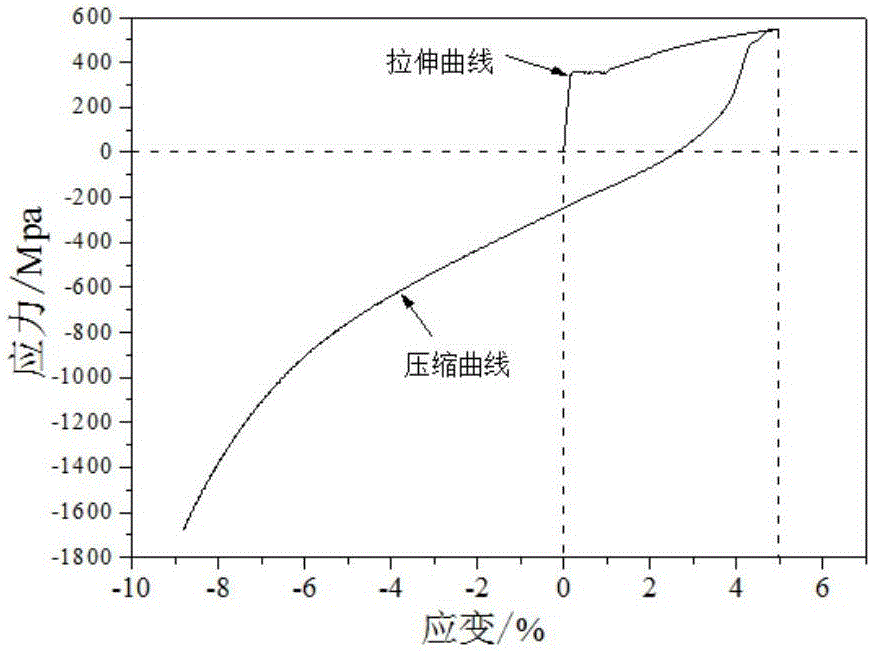

[0022] 2. The hot-rolled wire rod is processed and drawn by the user The area reduction rate of a single drawing pass is controlled at 25%.

[0023] Table 1 shows the mechanical properties of ¢6.5mm ferrite-pearlite type steel hot-rolled wire rod and the properties of steel wire after drawing.

[0024]

Embodiment 2

[0026] The present invention is used in the 160mm high line of Shougang 2 It has been applied in the production of Φ6.5mm wire rod, and non-quenched and tempered steel with excellent performance has been obtained.

[0027] 1 Stelmo air-cooling control, cover with insulation cover 5-18#, control the slow cooling rate of 3°C / s, and obtain a ferrite content of 45-50%;

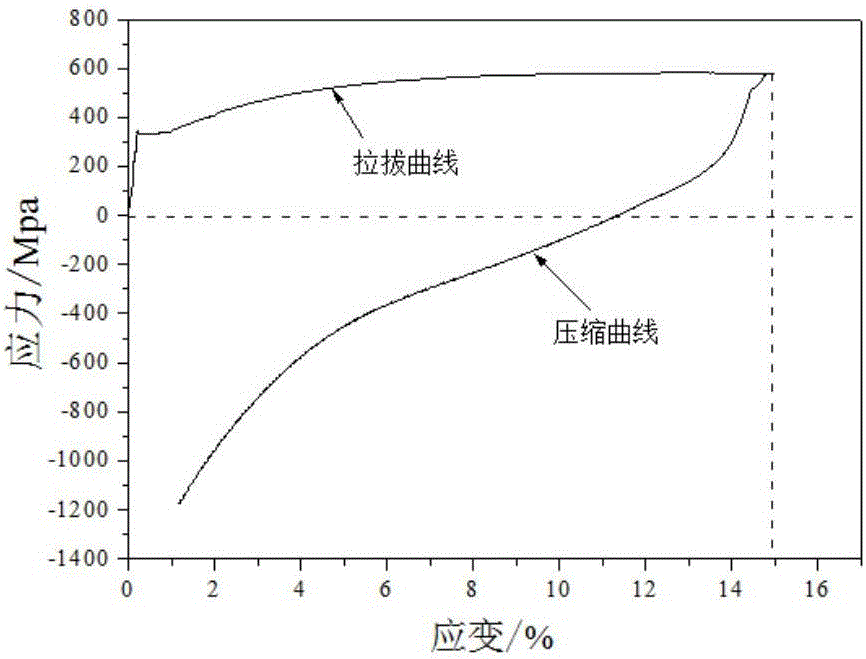

[0028] 2. The hot-rolled material is processed and drawn by the user The area reduction rate of a single drawing pass is controlled at 20%.

[0029] Table 1 shows the mechanical properties of φ6.5mm ferrite-pearlite type steel hot-rolled wire rod and steel wire properties after drawing.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com