Test sample for measuring plate Bauschinger effect, test fixture and test method

A technology of Bauschinger effect and test fixture, which is applied in the direction of applying stable torsion to test the strength of materials, measuring devices, and analyzing materials. Simple, easy-to-use, simple-to-structure effects for testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

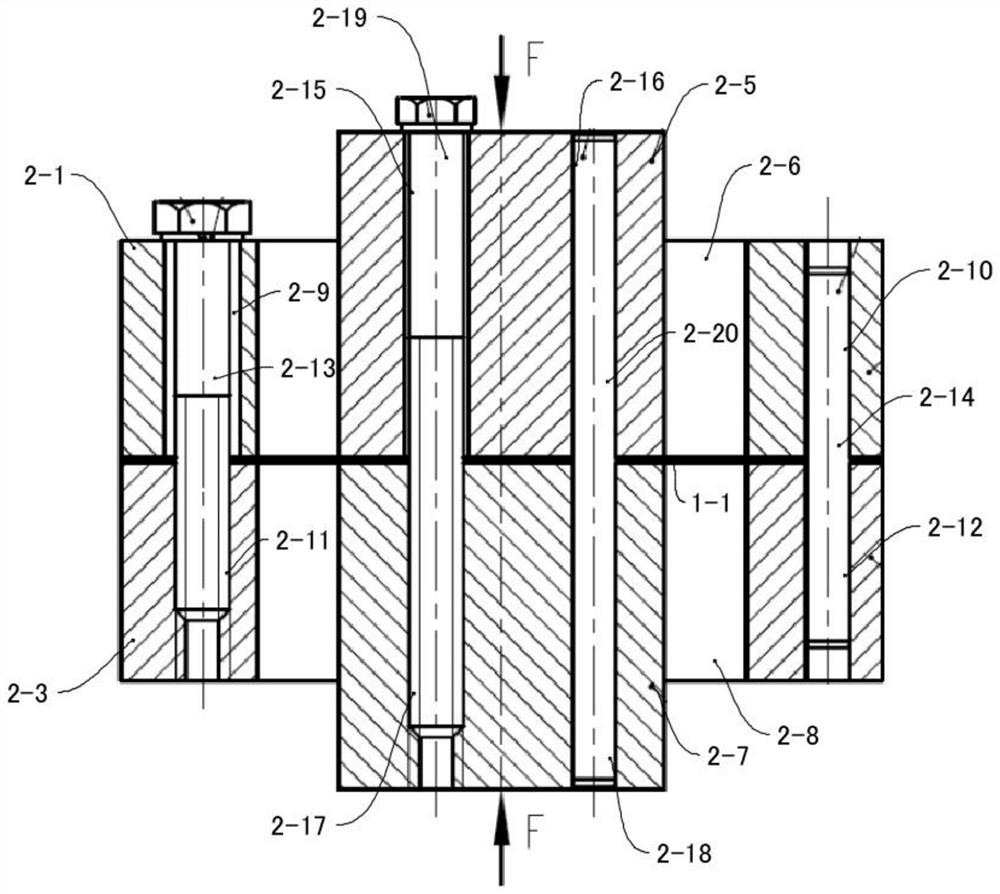

[0047] Embodiment: This embodiment provides a high-strength steel plate as a test fixture that matches the high-strength steel plate, and uses the test fixture to clamp the test sample to detect the Bauschinger effect of the test sample;

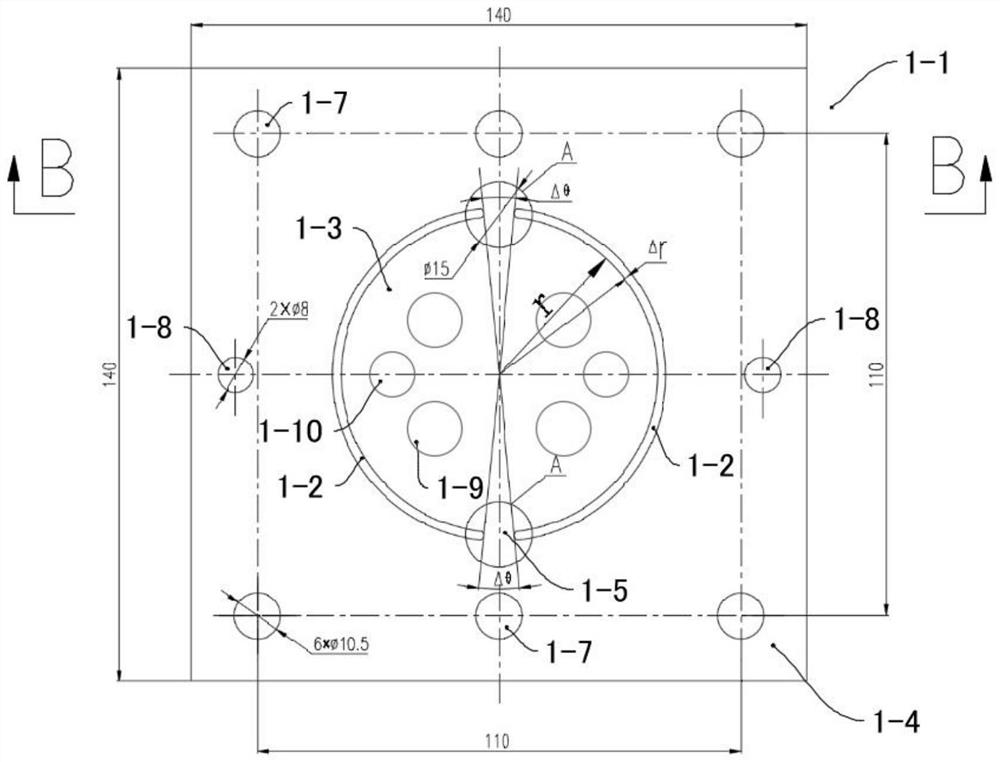

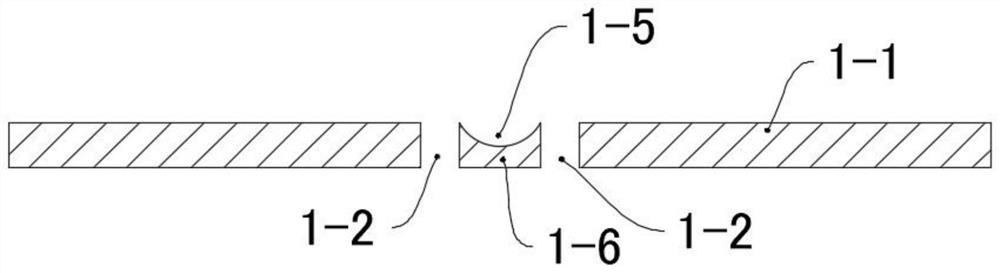

[0048] First, if figure 1 As shown, the test sample is specifically a square high-strength steel plate 1 with a length of 140 mm and a width of 140 mm. The plate 1 is provided with two axisymmetric semi-annular grooves 1-2, and a clamp is formed between the two semi-annular grooves 1-2. Holding area 1-3, two semi-annular grooves 1-2 form an active area 1-4, such as figure 1 As shown in A, the junction of the two semi-annular grooves 1-2 is two grooves 1-5, and the grooves 1-5 are arc grooves, and as figure 2 As shown, the arc groove is the bridge 1-6 of the two semi-annular grooves 1-2, and the reserved thickness of the bridge 1-6 is 1mm;

[0049] More specifically, such as figure 1 As shown, a number of first screw holes 1-7 and a numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com