Welded steel pipe for linepipe with superior compressive strength, and process for producing same

一种焊接钢管、制造方法的技术,应用在制造工具、焊接设备、金属轧制等方向,能够解决韧性变差、高钢管、DWTT性能降低等问题,达到高压缩强度、高强度、优异韧性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

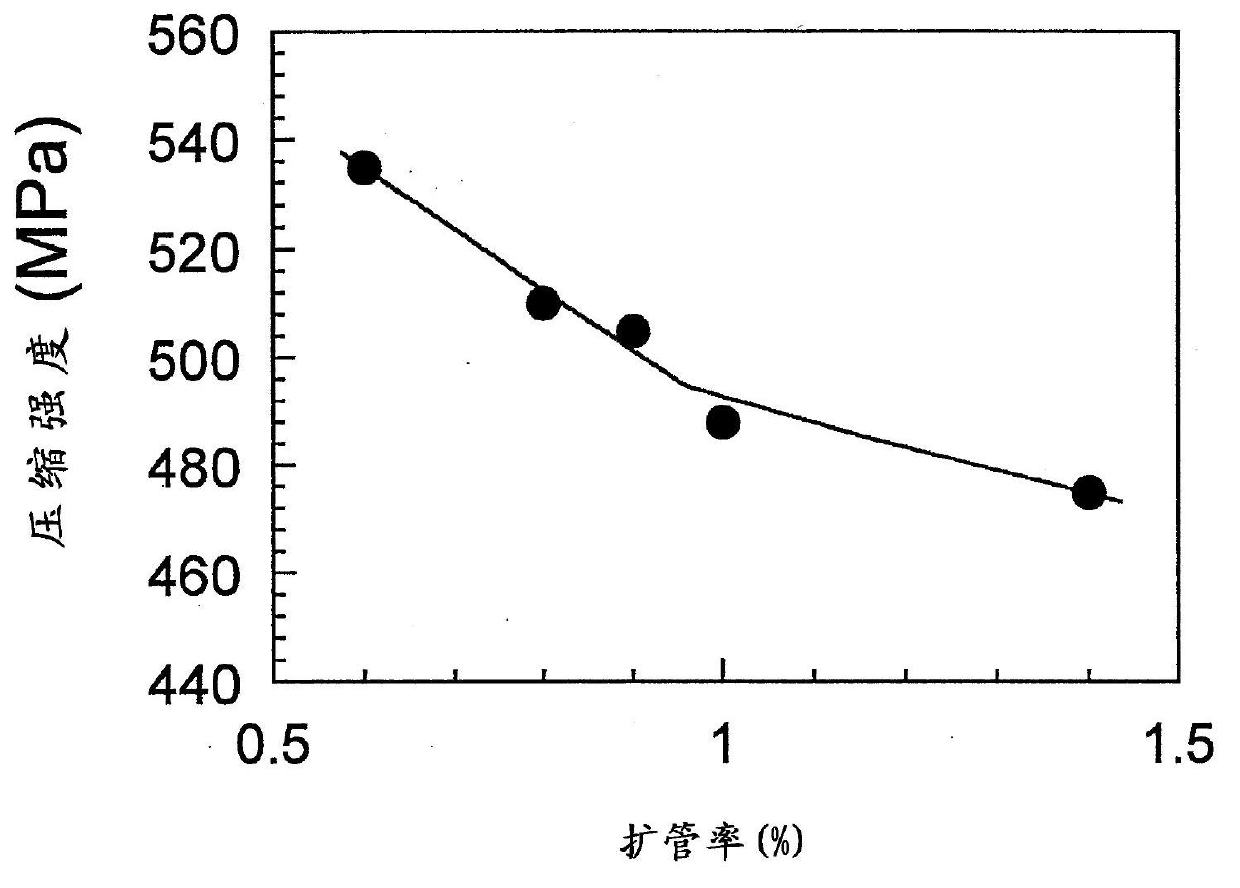

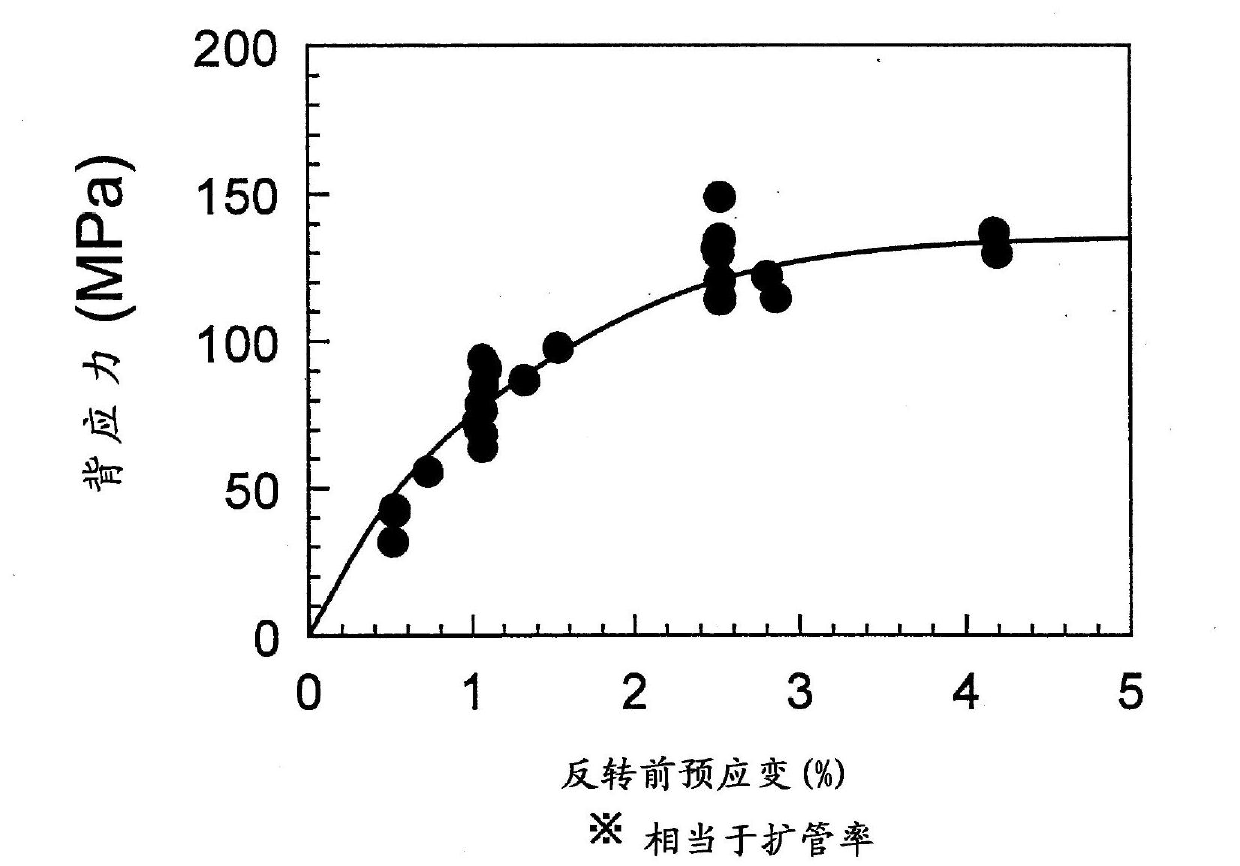

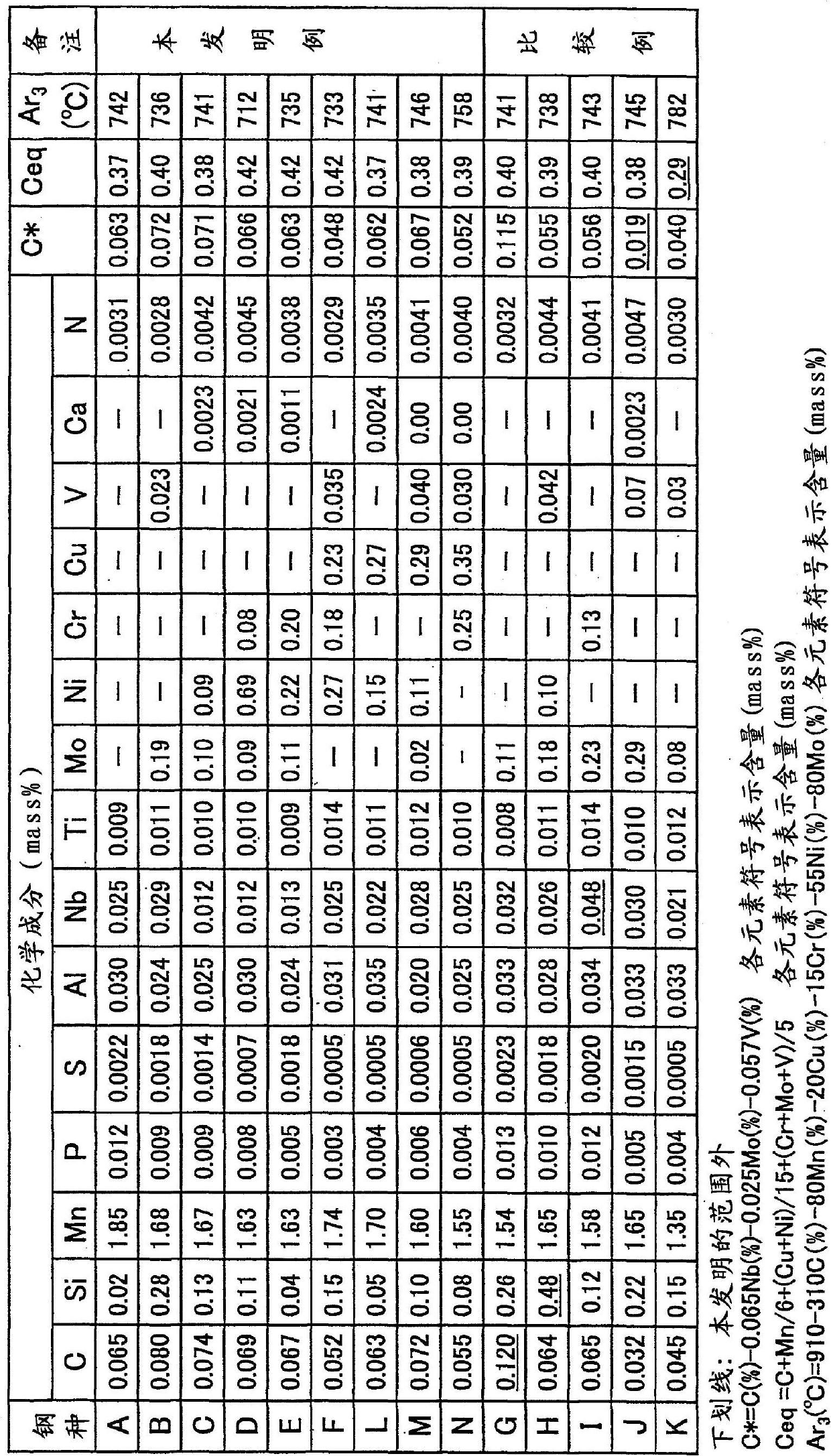

[0130] Steels (steel grades A to N) with the chemical compositions shown in Table 1 are formed into slabs by continuous casting process, and thick steel plates (No. 1 ~24). Table 2 shows the production conditions of the steel sheets. The reheating treatment at the time of manufacturing a steel sheet is reheating using an induction heating furnace installed on the same line as the accelerated cooling facility. The surface temperature at the time of reheating is the surface temperature of the steel sheet at the exit of the induction heating furnace, and the center temperature is the temperature of the steel sheet at the time when the surface temperature and the center temperature after heating become almost the same. Using these steel sheets, steel pipes of various outer diameters are manufactured by the UOE process. Table 2 also shows the pipe expansion ratio during steel pipe production.

[0131] For the tensile properties (tensile properties) of the steel pipes manufacture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com