Thermal recovery well casing material selection method

A thermal recovery well and casing technology, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problem that the casing does not meet the needs of thermal recovery wells, and achieve the effect of ensuring safe use and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

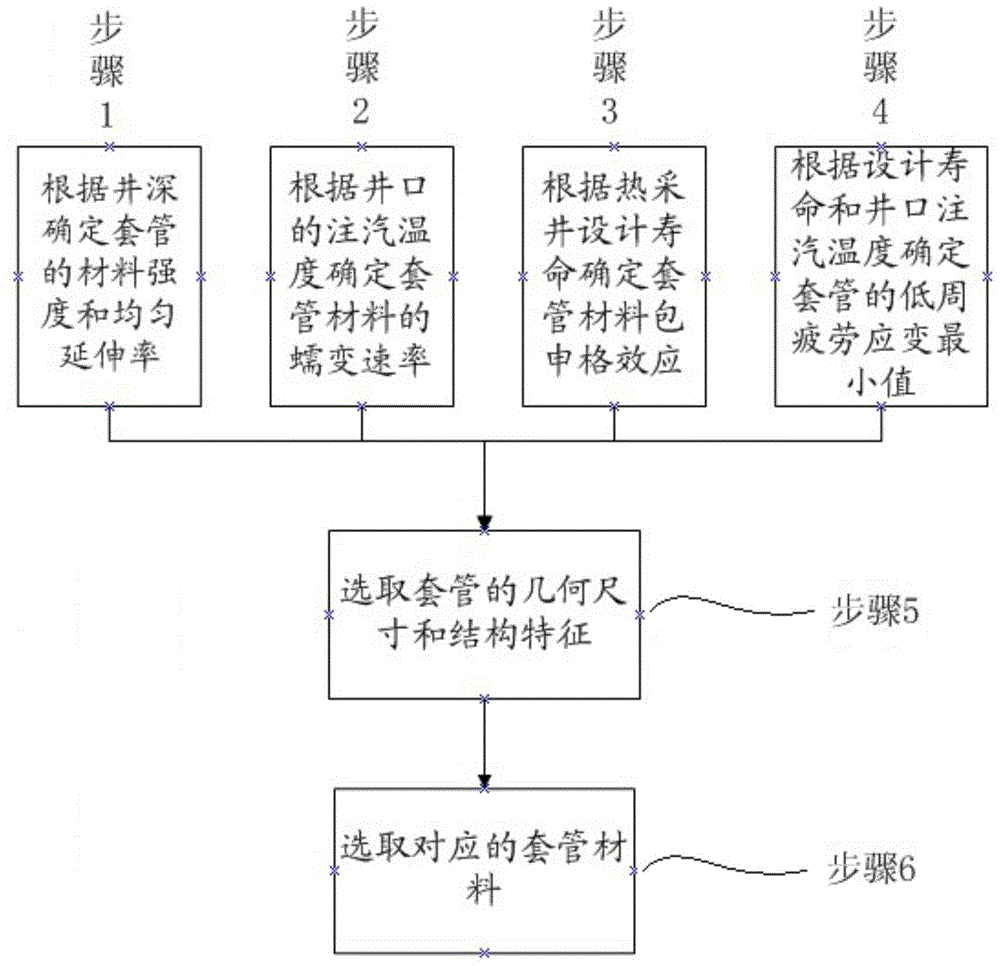

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a method for selecting a casing material for a thermal recovery well, and the method for selecting a casing material includes:

[0034] Step 1: Determine the material strength performance index and uniform elongation performance index of the casing material according to the depth of the thermal recovery well;

[0035] Step 2: Determine the creep rate performance index of the casing material according to the steam injection temperature at the wellhead of the thermal recovery well;

[0036] Step 3: Determine the Bauschinger effect performance index of the casing material according to the design life of the thermal recovery well;

[0037] Step 4: Determine the minimum low-cycle fatigue strain of the casing material according to the design life of the thermal recovery well and the steam injection temperature at the wellhead of the thermal recovery well;

[0038] Step 5: Select the geometric dimens...

Embodiment 2

[0058] Selection of Casings for Thermal Recovery Wells in Fengcheng District of Xinjiang Oilfield

[0059] Working condition:

[0060] 1) The well depth is 260 meters;

[0061] 2) The steam injection temperature at the wellhead is 260-300°C;

[0062] 3) The design life is 6 years;

[0063] 4) 3-4 rounds of steam injection per year.

[0064] Corresponding casing material performance index selection:

[0065] 1) The elastic limit is 450MPa, the tensile limit is 560MPa, and the uniform elongation is 4.5%;

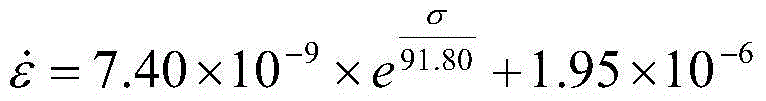

[0066] 2) Creep rate boundary equation: ϵ · = 7.40 × 10 - 9 × e σ 91.80 + 1.95 × 10 - 6

[0067] 3) Bauschinger effect index: 0.75;

[0068] 4) Low cycle fatigue strain t...

Embodiment 3

[0071] Selection of Casings for Thermal Recovery Wells in Hong 003 Area of Xinjiang Oilfield

[0072] Working conditions:

[0073] 1) The well depth is 560-600 meters;

[0074] 2) The steam injection temperature at the wellhead is 310-340°C;

[0075] 3) The design life is 10 years;

[0076] 4) 3-4 rounds of steam injection per year.

[0077] Corresponding casing material performance index selection:

[0078] 1) The elastic limit is 560MPa, the tensile limit is 660MPa, and the uniform elongation is 6.5%;

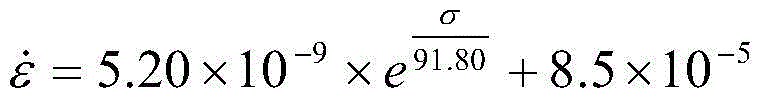

[0079] 2) Creep rate boundary equation: ϵ · = 5.20 × 10 - 9 × e σ 91.80 + 8 . 5 × 10 - 5

[0080] 3) Bauschinger effect index: 0.90;

[0081] 4) Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com