Method for determining thin plate reverse loading Bauschinger effect

A technology of Bauschinger effect and reverse loading, applied in the field of sheet stamping, can solve the problems of stress, uneven strain, complex stress state, serious edge effect, etc. Simple, accurate rebound effect

Inactive Publication Date: 2013-10-09

XI AN JIAOTONG UNIV

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the cyclic simple shear test, the obtained stress and strain are not uniform, the stress is in a complex state, and when the strain is large, the edge effect is very serious

In the tension-compression test, the thin plate is very easy to be unstable when co

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

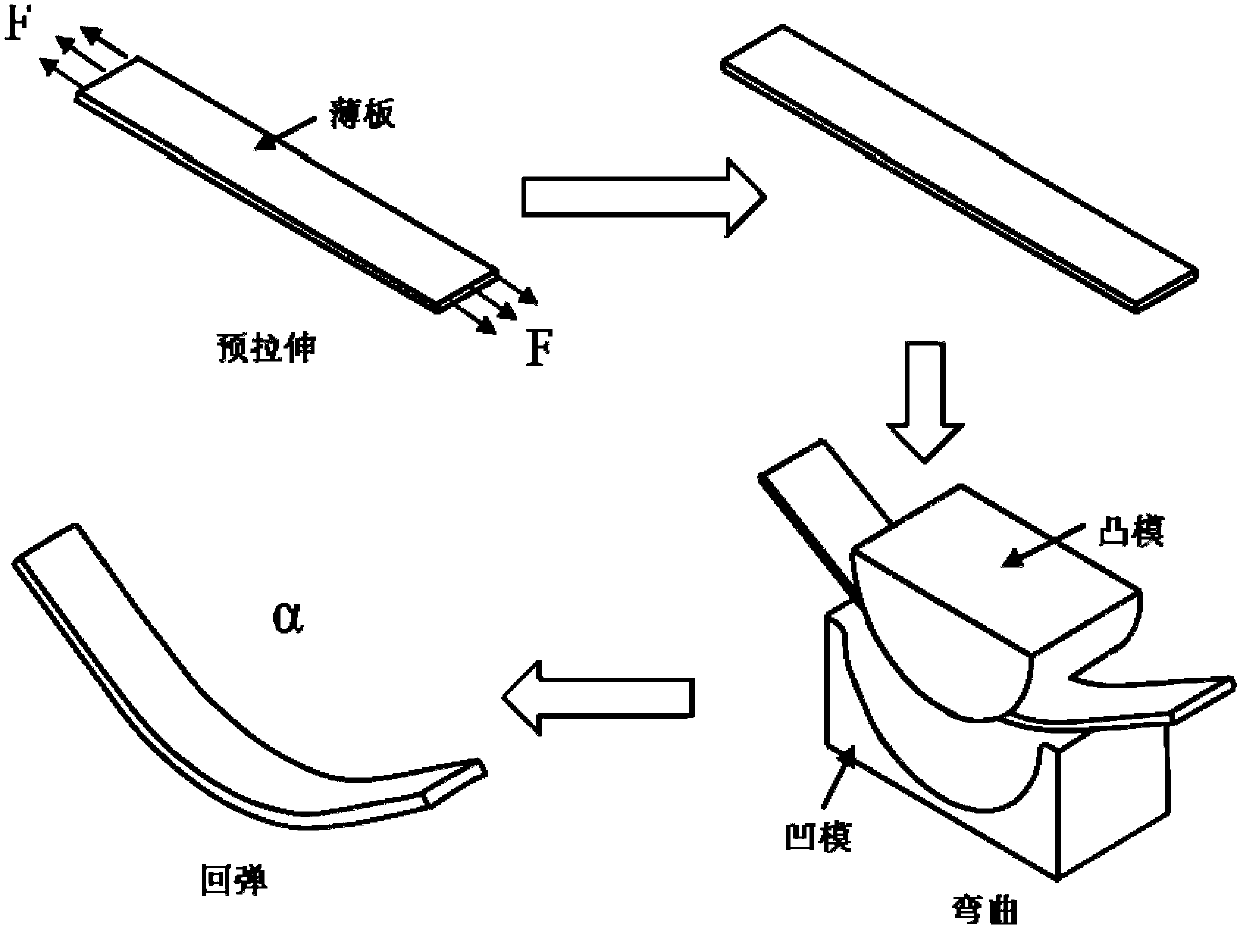

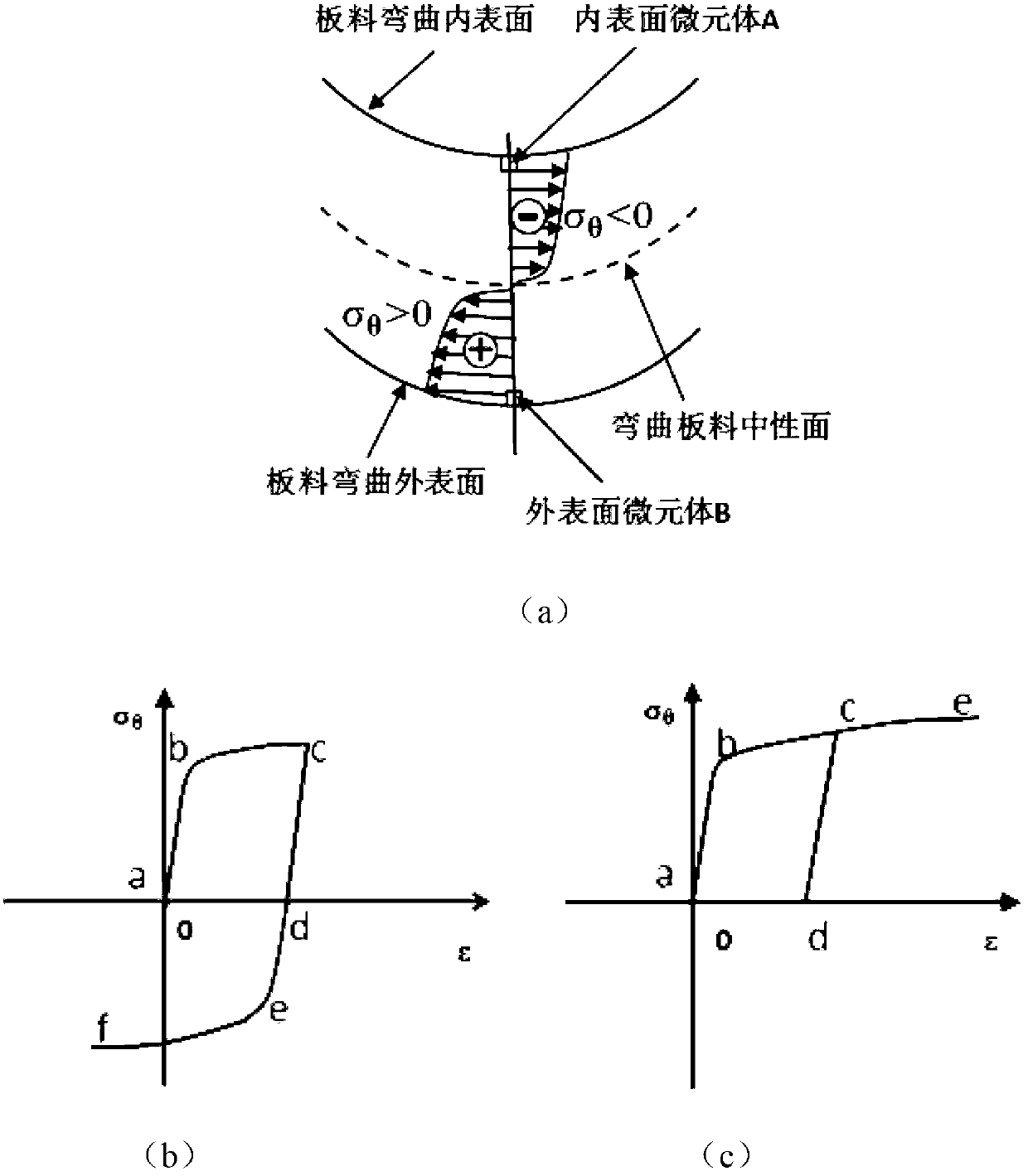

The invention discloses a method for determining thin plate reverse loading Bauschinger effect, and belongs to the field of thin plate stamping technology. The method comprises the following steps: 1) prestretching a to-be measured thin plate, unloading the prestretching force, then bending the thin plate, measuring deformation angle Z* after the thin plate rebounds; 2) measuring a series of the deformation angles Z* after the thin plate rebounds; 3) constructing a parameter model of the material of the to-be measured thin plate, endowing an initial value, and analog computing the thin plate rebounding angle to obtain a series of the deformation angles Z after the thin plate rebounds, comparing with the test result in step 2) till the difference of the two deformation angles reaches a preset threshold, and outputting a material parameter A which is obtained by calculating at the same time; and 4) carrying out finite element simulation by using the material parameter A to obtain a Bauschinger effect curve of the thin plate. The test apparatus and the data processing method are simple, mechanical testing data in larger strain can be obtained, influence factors are less and parameters are accurate.

Description

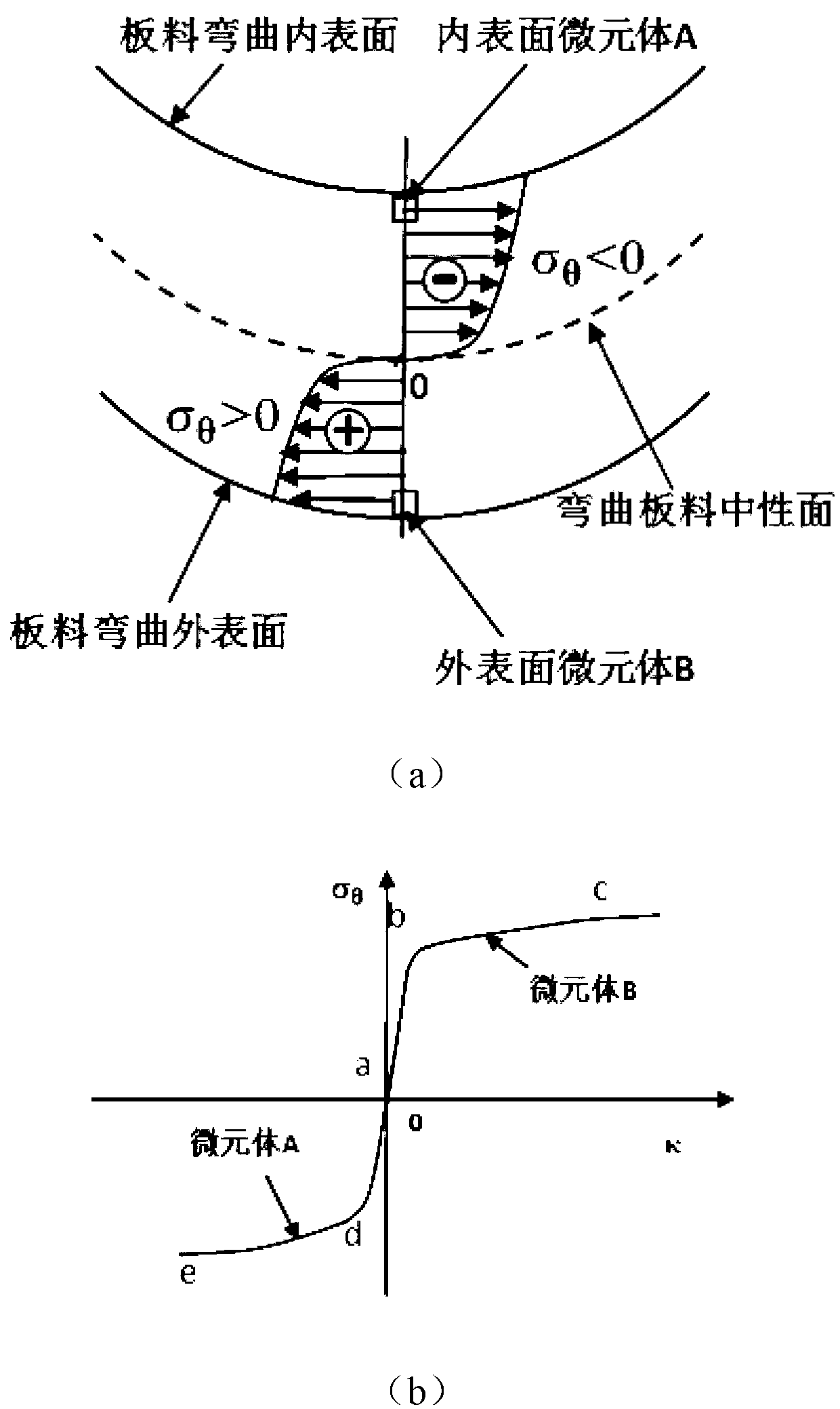

technical field [0001] The invention belongs to the technical field of sheet stamping, and in particular relates to a method for measuring the Bauschinger effect of reverse loading of a sheet. Background technique [0002] During plastic processing of metals, forward loading induces plastic strain strengthening, resulting in plastic strain softening (lower yield limit) of the metal material during subsequent reverse loading. This phenomenon was discovered by J. Bauschinger in 1886 in experiments on the mechanical properties of metal materials, and it is called the Bauschinger effect. [0003] Springback is one of the most important and difficult to control defects in sheet metal stamping, and the constitutive model of sheet is the key to high-precision prediction of springback by finite element method. At present, the constitutive model is insufficient to describe the mechanical properties of thin plates under variable path loading, which is the bottleneck that hinders the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/00

Inventor 臧顺来牛超李少鹏

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com