Apparatus and method for precisely detecting Bauschinger effect of repeated bending of metal plate

A Bauschinger effect and repeated bending technology, applied in the field of mechanical property testing and sheet metal physical properties, can solve the problems of low precision, affecting test data, and large error of test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

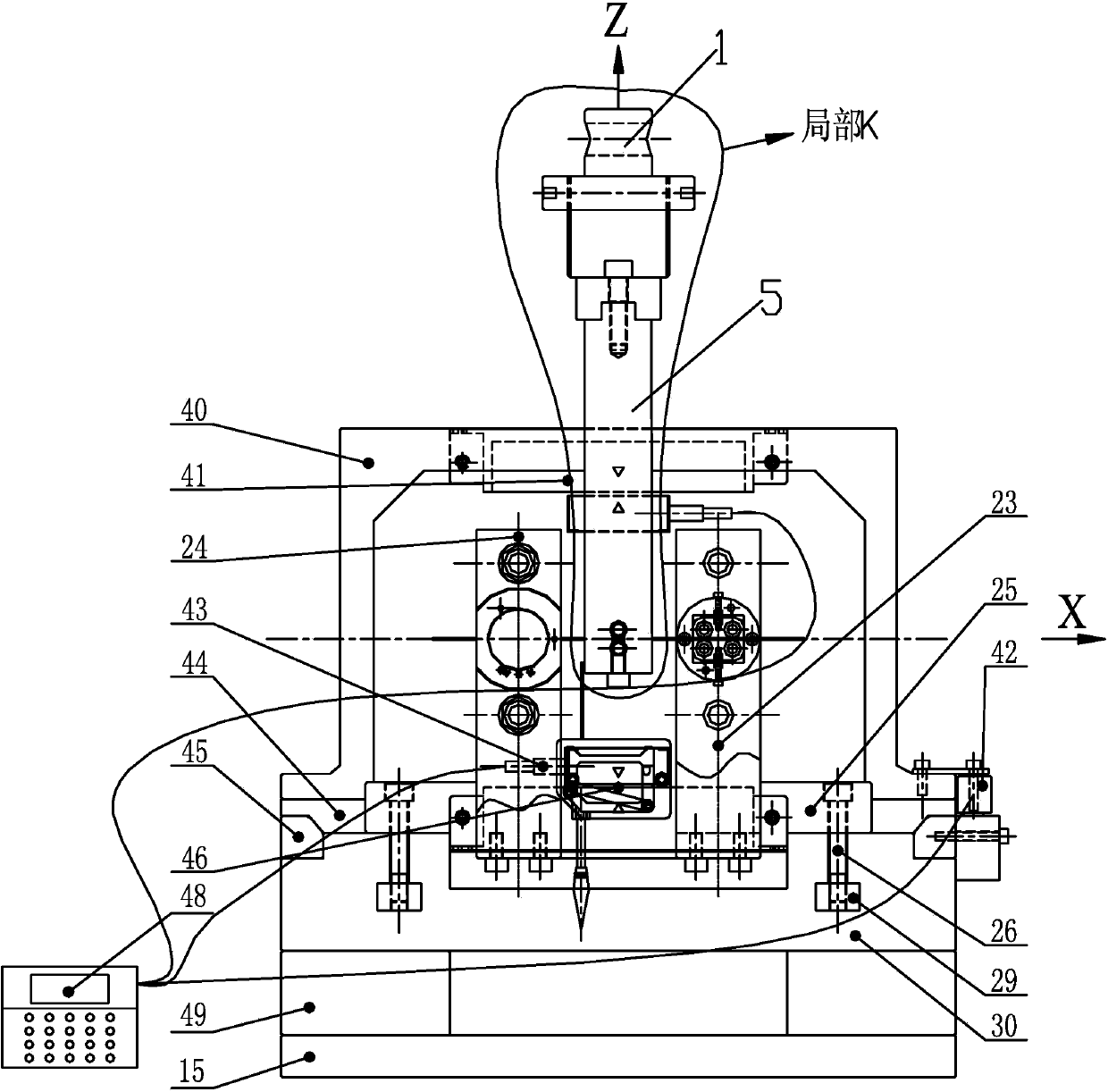

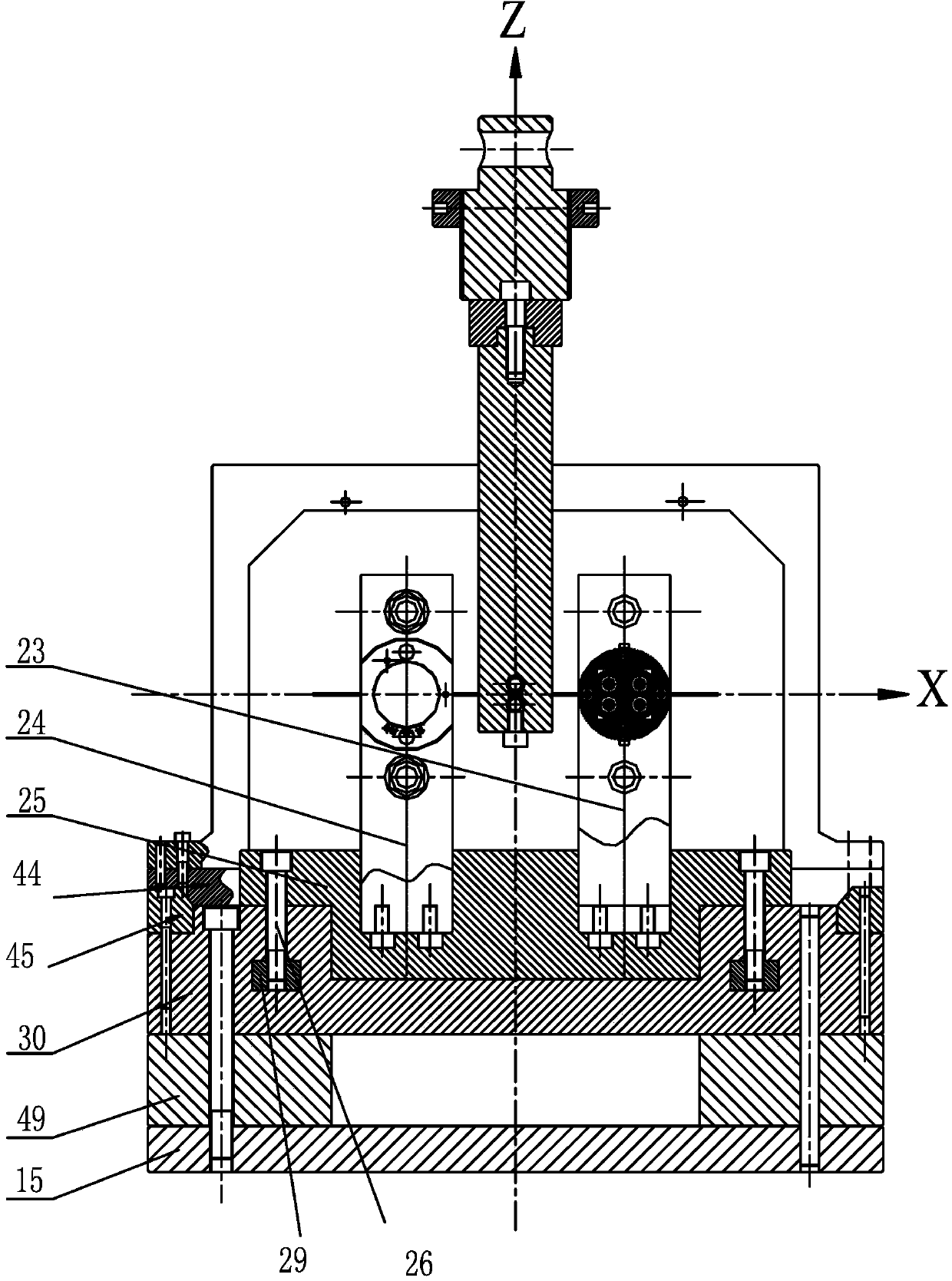

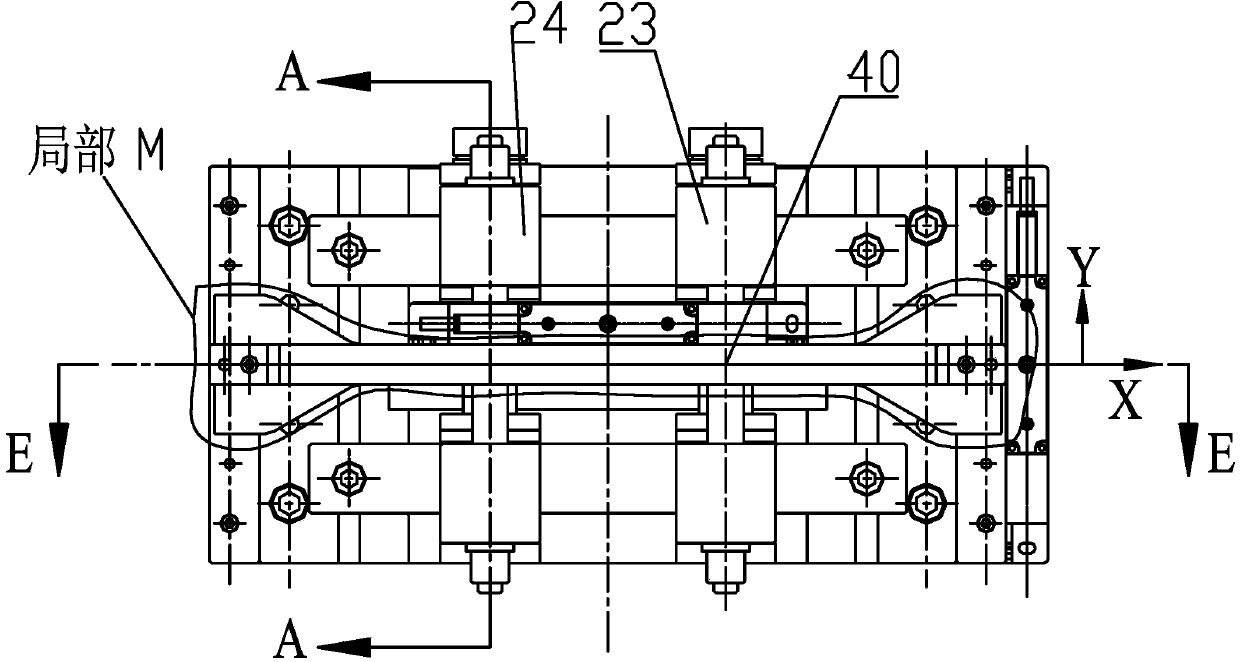

[0037] Attached below Figure 1-14 The structure, principle and working process of the present invention are further described.

[0038] Such as Figure 1-7 As shown, the precision detection device for repeated bending of metal sheet metal according to the present invention includes a mechanical loading module, a sheet metal clamping adjustable module with front and rear loading brackets 5 fixed at the bottom of the mechanical loading module; the mechanical loading module The testing machine is fixed and suspended in the air and set up vertically, and the X-direction adjustment blocks (24, 23) for adjusting the flatness of the sheet metal are arranged symmetrically on the left and right sides of the mechanical loading module and the sheet metal clamping adjustable module X direction, and each X direction The front and rear ends of the adjustment blocks (24, 23) are respectively fixed on the Y direction adjustment blocks (the Y direction front adjustment block 25 and the Y dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com