DIC-based Bauschinger effect test sample, fixture and method

A Bauschinger effect and test fixture technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as easy instability, and achieve the effects of small deformation area, high test efficiency and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

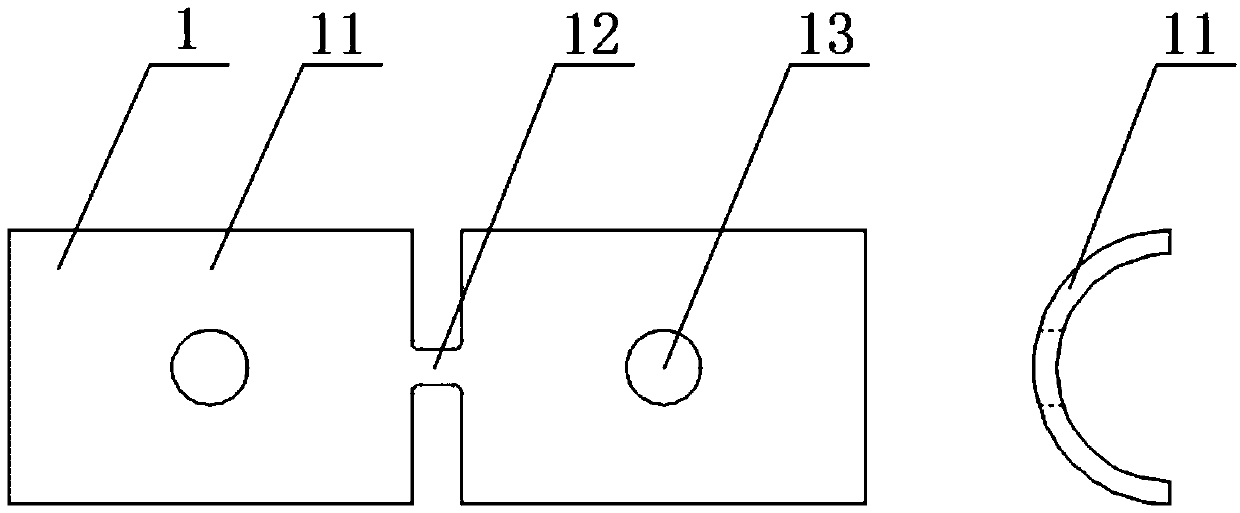

[0034] Such as figure 1 As shown, a kind of Bauschinger effect test sample based on DIC comprises a connecting body 12 and two sample bodies 11 arranged symmetrically, the two sample bodies 11 are connected through the connecting body 12, and the two Holes 13 are provided on each of the sample bodies 11, and the sample bodies 11 are in the shape of a semicircle.

[0035] Specifically, the length of the sample body 11 is 30mm, the outer diameter is 12mm, and the thickness is 1.9mm, the length of the connecting body 12 is 3.9-4.1mm, the width is 1.9-2.1mm, and the diameter of the opening 13 is 6mm. .

[0036] The small gauge sample 1 used in the DIC-based Bauschinger effect test sample in Example 1 is smaller than the critical instability wavelength in a low stress state, so the critical instability force can be delayed without lateral restraint The generation of (critical instability point) can obtain more objective compressive strain, the deformation area is small, the defor...

Embodiment 2

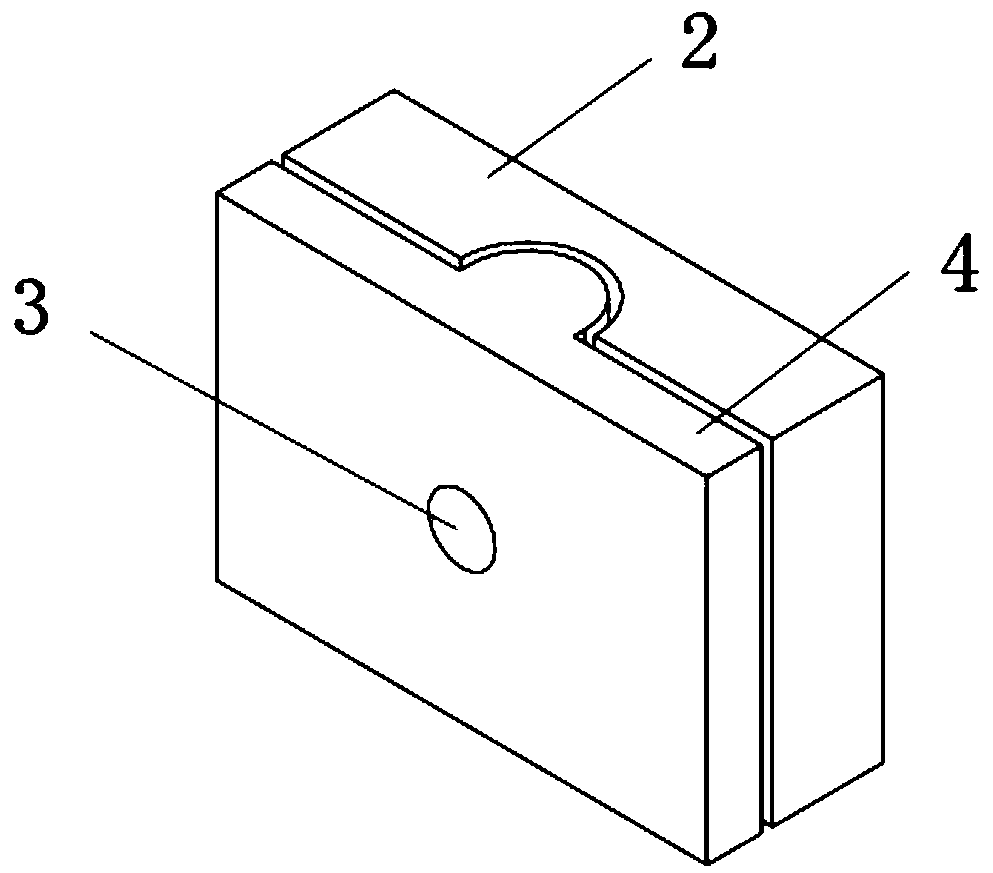

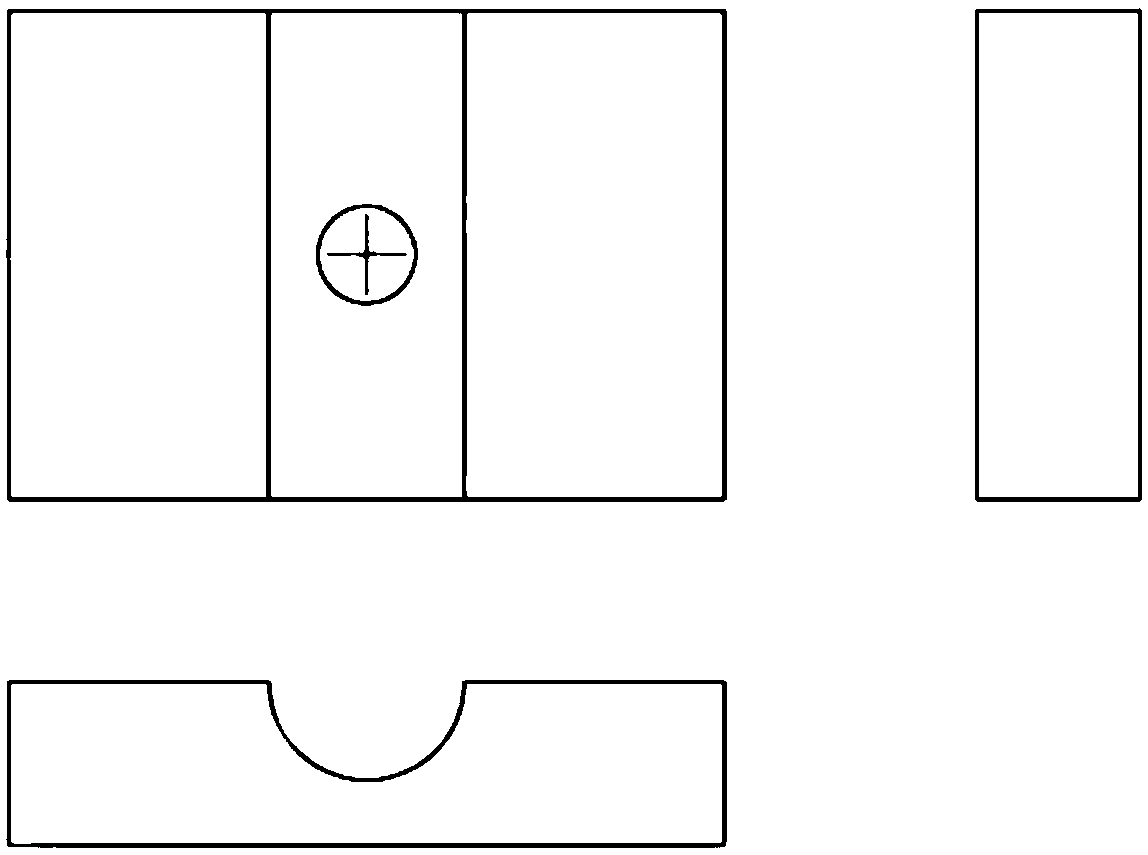

[0038] Such as Figure 2 to Figure 5 Shown, a kind of Bauschinger effect test fixture based on DIC comprises first fixture 2, second fixture 4 and pin 3, and described first fixture 2 is rectangular parallelepiped and middle part is provided with semicircular groove longitudinally, and described half The longitudinal middle part of the circular groove is provided with a first matching hole, the second fixture 4 is a cuboid and the middle part is longitudinally fixed with a protrusion, and the longitudinal middle part of the protrusion is provided with a second matching hole, and the pin 3 is sequentially connected with the first fitting hole. A matching hole and the second matching hole are matched and connected, and the protrusion of the second clamp 4 presses and fixes the sample 1 in the semicircular groove of the first clamp 2 .

[0039] Specifically, the first fixture 2 is 44mm long, 30mm wide, and 10mm high, and the radius of the semicircular groove is 6mm. The second fi...

Embodiment 3

[0043]Such as Figure 6 As shown, a method for testing the Bauschinger effect based on DIC, using the described Bauschinger effect test fixture based on DIC to test the sample 1, the specific steps are as follows:

[0044] Step 1, making small gauge sample 1: for thin-walled tube blanks, process the tube blanks into small gauge sample 1 by wire cutting according to the size;

[0045] Step 2, speckle production and clamping of sample 1: first uniformly spray a layer of white paint on the gauge section of sample 1, and after the paint is dry, spray uneven black spot-like paint to make speckle sample 1, And clamp the sample 1 on the test fixture;

[0046] Step 3, digital speckle system calibration: turn on the electronic universal testing machine and digital speckle system, set the focal length in the focal plane where sample 1 is located, adjust the aperture size to obtain a clear speckle picture, and then use the calibration board to carry out Calibration of the digital speck...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com