Thin-film encapsulation structure and organic light-emitting diode display thereof

A light-emitting diode and thin-film packaging technology, which is applied in the direction of organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., can solve problems such as the inability to reflect the density of inorganic thin-film layers and water-repellent film quality, the inability to optimize, and the monitoring of coating quality. Achieve the effect of reducing non-luminous dark spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

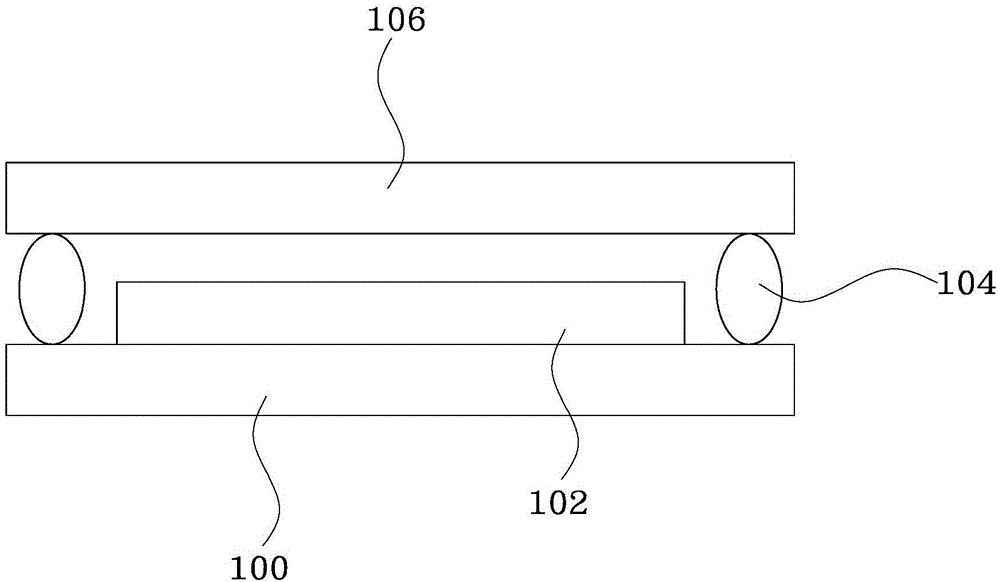

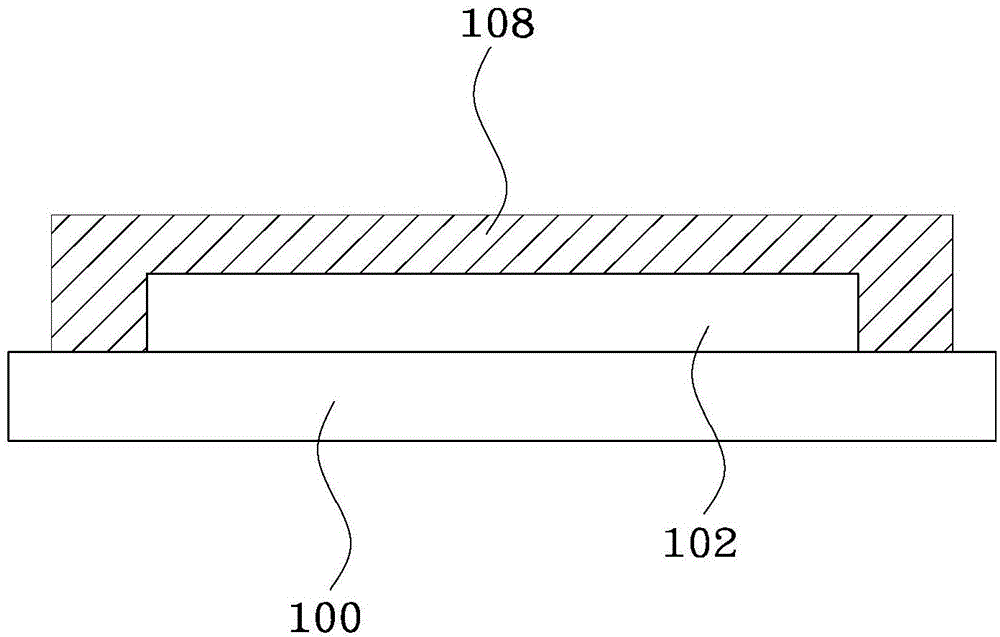

[0038] Figure 1A A schematic diagram showing a packaging structure of an organic light-emitting diode based on adhesive bonding in the prior art.

[0039] refer to Figure 1A, the conventional OLED display includes a first glass substrate (first glass substrate) 100 , an OLED 102 , a sealing layer (sealant) 104 and a second glass substrate (second glass substrate) 106 . Here, the second glass substrate 106 may also be referred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com