Method and device for quickly detecting bauschinger effect value of pipeline steel in steel plate production field

A Bauschinger effect, pipeline steel technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of loss, control of low rolling temperature, micro cracks on the edge of the steel plate, etc., achieve simple and feasible operation, and avoid detection errors , the effect of fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

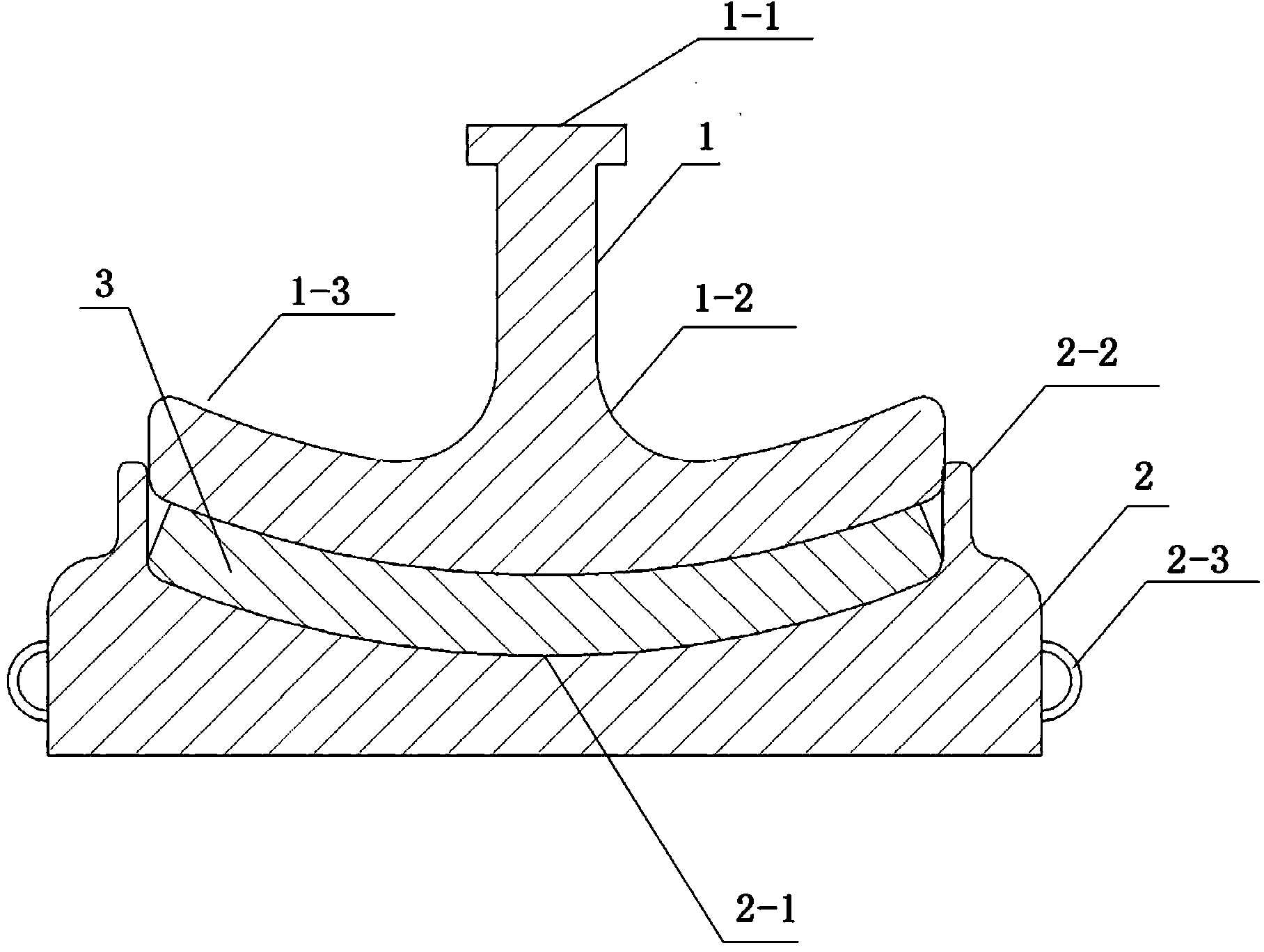

[0027] Such as figure 1 As shown, it is a schematic diagram of the working state of a multifunctional mold of the present invention, including an upper die 1 and a lower die 2, the upper die 1 is composed of a slider 1-1, a transmission shaft 1-2 and a punch 1-3, and the slider 1 -1 is connected with the notch on the power device of the press in a bayonet way, which is convenient for disassembly and assembly; the transmission shaft 1-2 plays the role of power transmission, and is smoothly connected with the punch to prevent fatigue cracks caused by stress concentration; punch 1- The outer arc diameter of 3 is identical with the diameter of the steel pipe made by the steel plate, and getting the steel pipe diameter among the present invention is 1016mm. The upper end surface of the lower mold 2 is provided with an arc-shaped punching groove 2-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com