Anti-buckling clamping device, sample and assembling method thereof

A clamping device, anti-buckling technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the influence uncertainty of data processing, limit the in-depth understanding of materials, material friction coefficient It can avoid buckling instability, break through limitations, and eliminate friction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

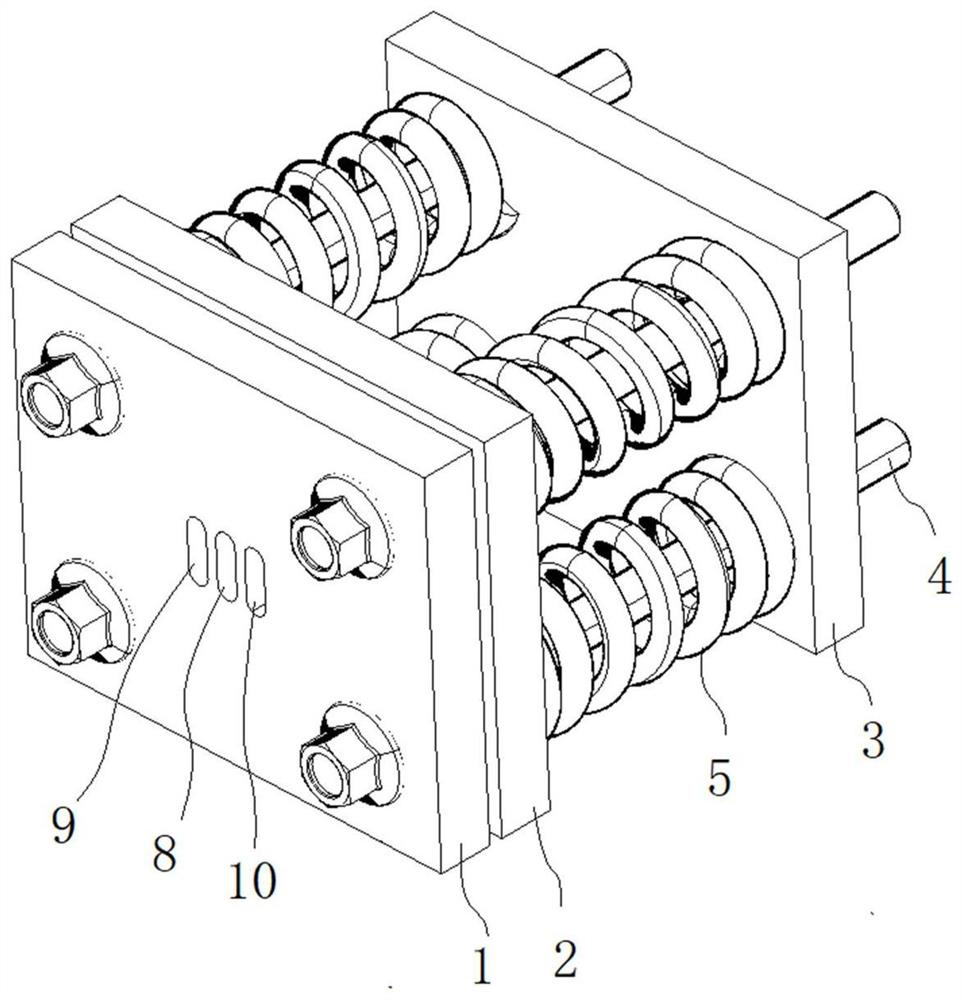

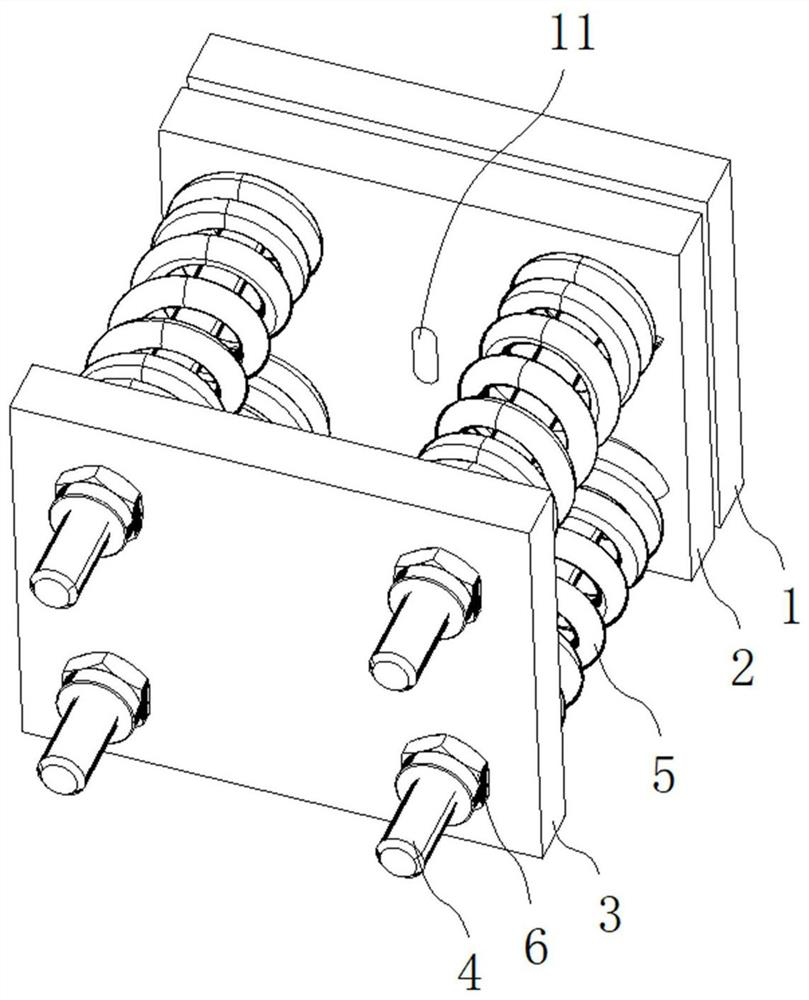

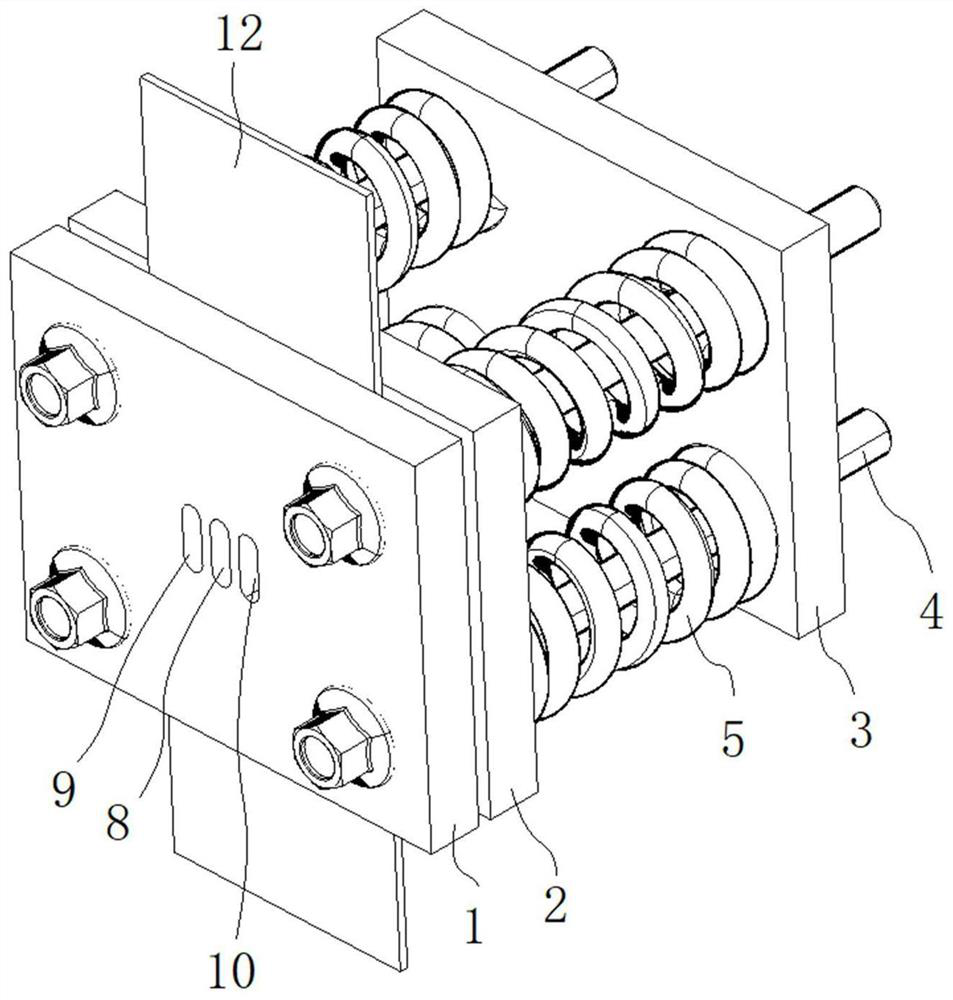

[0094] see Figure 1-7 , the anti-buckling device shown is an embodiment of the present invention, including an outer splint 1, an inner splint 2, a spring pressure plate 3, a bolt 4, a coil spring 5 and a nut 6. The bolt 4 runs through the bolt hole 7 of the outer splint 1, the inner splint 2, and the spring pressure plate 3, wherein the sample 12 is clamped between the outer splint 1 and the inner splint 2 (such as image 3 As shown), the coil spring 5 is clamped between the inner splint 2 and the spring pressure plate 3. The specific method is to insert the coil spring 5 into the bolt 4, and the tail end of the bolt 4 passes through the bolt hole 7 of the spring pressure plate 3, and uses the nut 6 lock (such as figure 2 shown).

[0095] see further image 3 , the outer splint 1 and the middle of the inner splint 2 are respectively provided with an outer state depression 8 (such as Figure 5 shown) and the inner state recess 11 (such as Figure 6 As shown), the centra...

Embodiment 2

[0105] This embodiment provides a sample matched with the anti-buckling clamping device of Embodiment 1, which is characterized in that:

[0106] The sample 12 includes the clamping end 22, the transition zone 23 and the gauge length section 24, and its geometric shape adopts a plane symmetrical design, as shown in FIG. 9 .

[0107] The width of the clamping end 22 is equal to the width of the outer splint 1 , and a bolt gap 25 is provided to realize automatic alignment of the sample 12 and the anti-buckling clamping device in the compression direction.

[0108] The gauge section 24 has a width equal to the distance between the two central axes of the left observation recess 9 and the right observation recess 10, so as to observe the "uniform neck expansion" and "local neck expansion" of the sample 12.

[0109] The position of the bolt notch 25 corresponds to the bolt hole 7 on the outer splint 1, and its width is equal to the diameter of the bolt 6, so as to limit the lateral...

Embodiment 3

[0112] In this embodiment, on the basis of Embodiment 1 and Embodiment 2, the assembly method of the anti-buckling device of the present invention is described in detail, and the steps include:

[0113] In the first step, insert bolts to the outer splint 1. Put the side of the outer splint 1 with the recess facing upwards, insert bolts 4 into each bolt hole of the outer splint 1, and the bolts 4 pass through the bolt holes 7 in the same direction, as shown in Figure 9(a) and Figure 9 (b) shown.

[0114] In the second step, the polytetrafluoroethylene film 13 is arranged. On the side facing the bolt 4, a polytetrafluoroethylene film 13 is placed on the outer splint 1, as shown in Figure 10 (a) and Figure 10 (b), its thickness is 0.1mm, the polytetrafluoroethylene film 13 The plane size of the outer splint is the same as that of the outer splint 1, and the position, size and number of openings on it are consistent with the outer splint 1.

[0115] In the third step, sample 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com