Continuous progressive diameter expansion and rounding device and method for thick-walled metal straight seam welded pipe

A straight seam welded pipe and progressive technology, which is applied in the field of continuous and progressive diameter expansion and rounding devices for thick-walled metal straight seam welded pipes, can solve the problems of large force required, high investment, and huge equipment structure, so as to eliminate internal and external stress. difference, reducing residual stress, reducing the effect of the Singer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

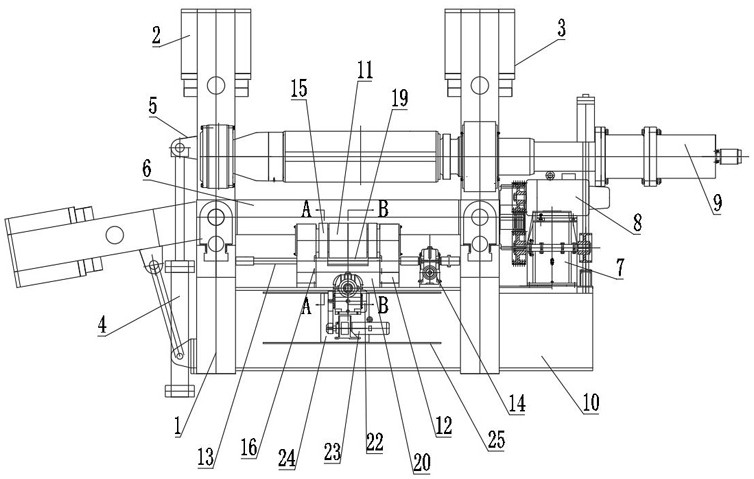

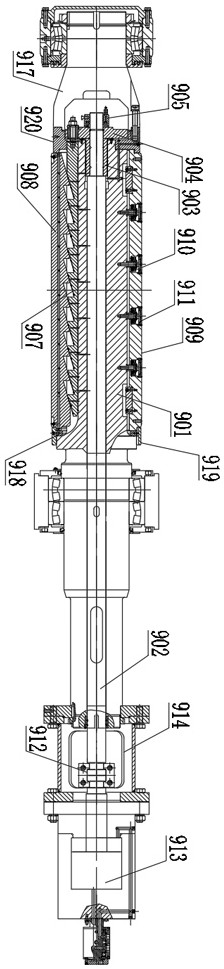

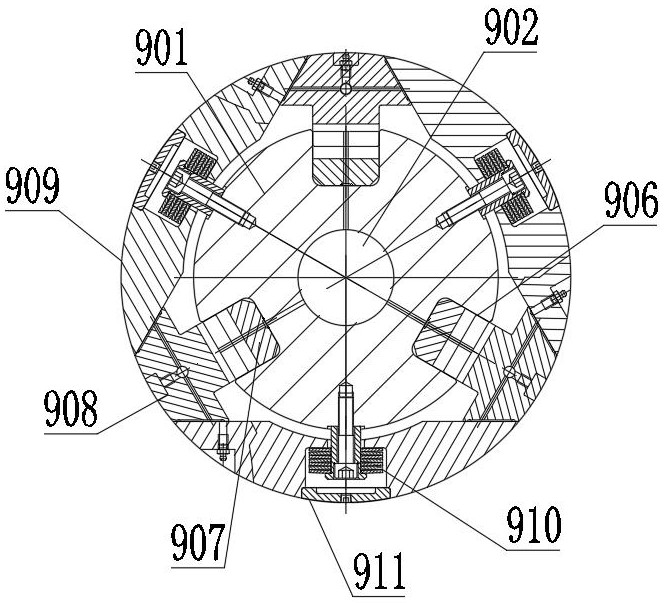

[0023] Such as Figure 1 to Figure 8As shown, a thick-walled metal straight seam welded pipe continuous progressive diameter expansion and full circle device includes two left and right bases 1, and a left frame 2 and a right frame 3 are respectively arranged on the tops of the left and right bases 1, The left frame 2 is hinged with the corresponding base 1, and an overturning hydraulic cylinder 4 is arranged on the outside of the left frame 2, and the piston rod of the overturning hydraulic cylinder 4 is hinged with the left frame 2 through a hinge seat 5, so that The cylinder body of the overturning hydraulic cylinder 4 is hinged with the base 1 below the left frame 2 through the hinge seat 5, and the overturning hydraulic cylinder 4 can realize the overturning of the left frame 2, and finally realize the rapid loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com