Bauschinger Effect Evaluation Method for Casing in Heavy Oil Steam Huff and Puff Thermal Recovery Wells

A technology of the Bauschinger effect and evaluation method, which is applied in the direction of testing the strength of materials by applying repetitive force/pulse force, and can solve problems such as scrapping, wellbore damage, and wellbore instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a Bauschinger effect evaluation method for casings used in heavy oil steam huff and puff thermal recovery wells. The evaluation method includes the following steps:

[0032] S1, the measured initial yield strength σ of the casing material under evaluation 0 and tensile strength σ t . Preferably, the casing material to be evaluated is a round bar sample, the surface roughness within the gauge range is less than or equal to R0.8, and the gauge length is greater than or equal to 5 times the diameter. Obtain the initial yield strength σ of the casing material under evaluation 0 and tensile strength σ t When using uniaxial stretching method, the stretching rate is less than or equal to 0.5mm / min. Among them, the initial yield strength is the stress corresponding to the residual plastic deformation of 0.2%.

[0033] S2, in step S1, the casing sample is taken from the casing material under evaluation, and the casing sample is subjected to multiple...

Embodiment 2

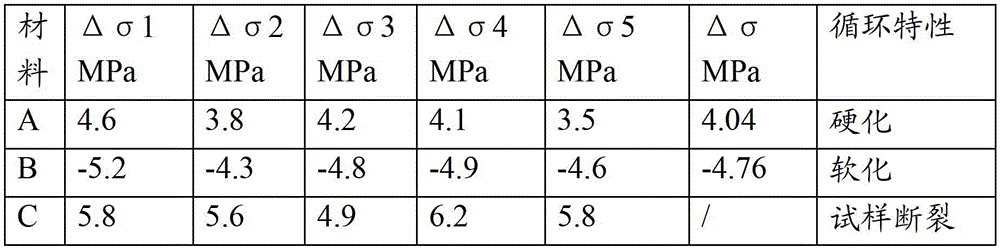

[0045] The embodiment of the present invention provides a Bauschinger effect evaluation method for casings used in heavy oil steam huff and puff thermal recovery wells. The Bauschinger effect evaluation method uses three casing materials for thermal recovery wells in a domestic oilfield as evaluation objects , the specific evaluation steps and situations are as follows:

[0046] Working condition:

[0047] 1) The depth of the well is about 260 meters;

[0048] 2) The steam injection temperature at the wellhead is 260-300°C;

[0049] 3) The design life is 6 years;

[0050] 4) 3 to 4 rounds of steam injection per year;

[0051] 5) The casing steel grade is N80.

[0052] Evaluation process:

[0053] 1) The three casing materials are numbered A, B, and C respectively, and the uniaxial tensile specimens (that is, the initial yield strength σ 0 and tensile strength σ t The diameter of the gauge section is 6.5mm, the gauge length is 40mm, the end is M16 thread, the transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com