Experimental device for steel plate Bauschinger effect coefficient measurement

A technology of Bauschinger effect and experimental device, which is applied in the field of experimental device for measuring the coefficient of Bauschinger effect of steel plates, can solve the problems of unstable bending, affecting the accuracy of compressive yield strength, etc. The effect of high guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention and its specific implementation will be further described in conjunction with the accompanying drawings.

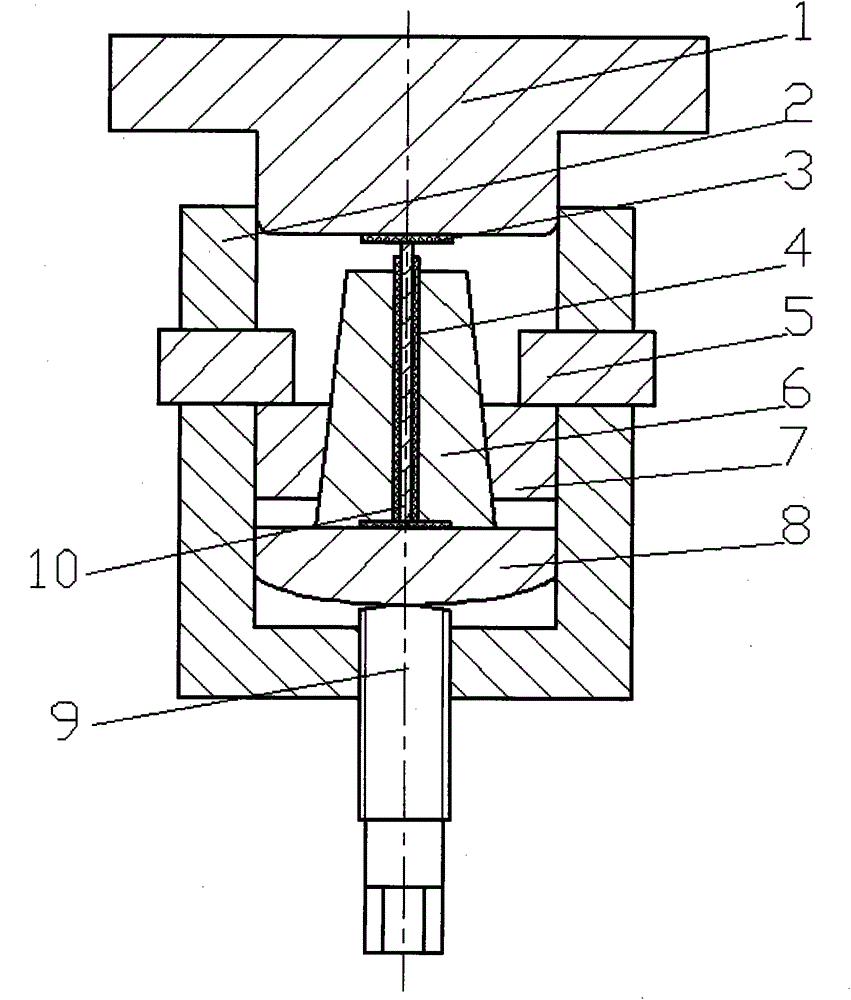

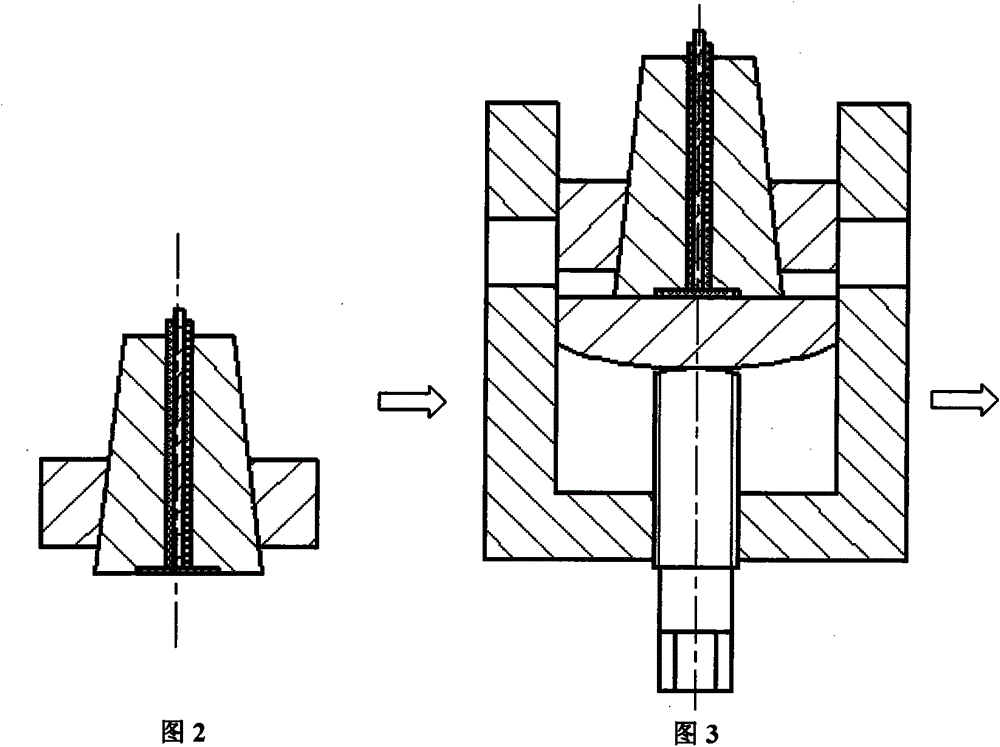

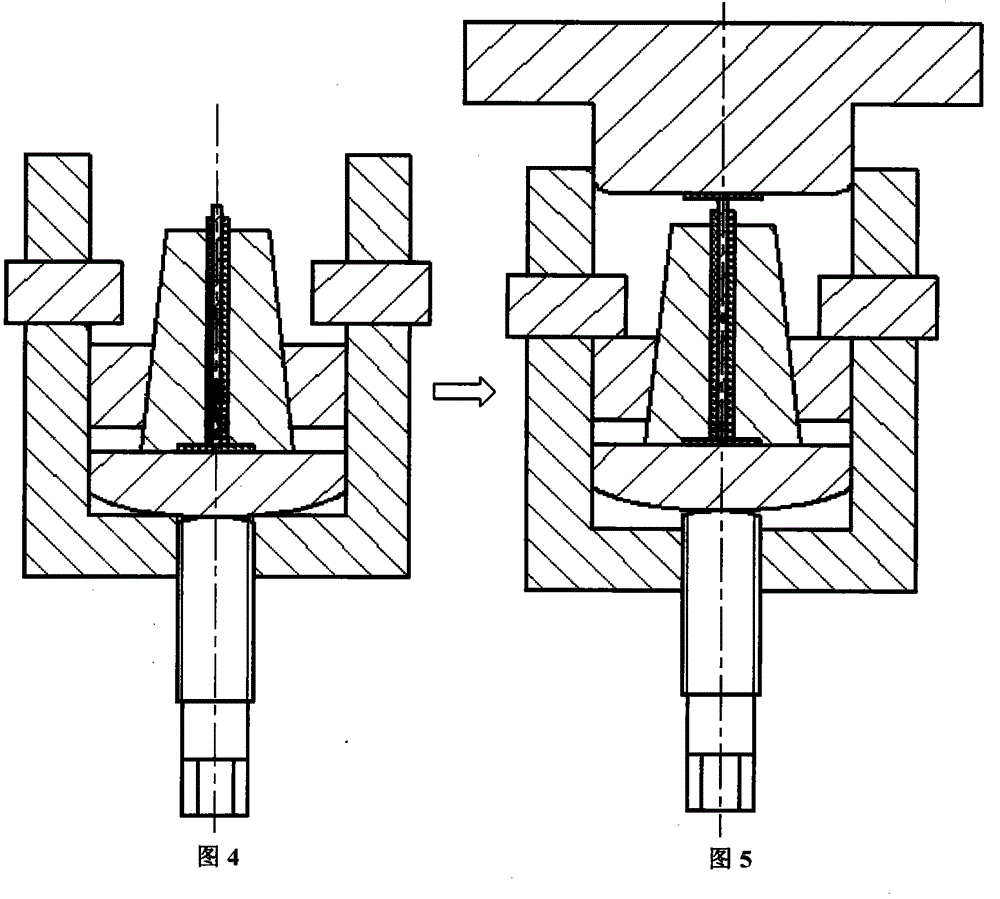

[0015] The device is attached figure 1 , including 1. Press block; 2. Main cylinder; 3. Plastic spacer; 4. Side spacer; . Main parts such as top wire, 10 is the sample to be compressed. First put the spherical supporting plate 8 into the bottom of the main cylinder 2, adjust the jacking wire 9 to lift the spherical supporting plate 8 to an appropriate height, stick the side spacers 4 on both sides of the sample 10, and then use two conical The pressure block 6 is tightly attached to the side gasket, and then the tapered ring 7 is set on the outside of the tapered pressure block 6. After the initial alignment and compression of the sample, it is placed on the spherical support plate 8 in the main cylinder 2. And lower the top wire 9, so that the tapered ring 7 and the sample 4 are lowered to a suitable position below the round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com