Granulator

A granulator and silo technology, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of powder, low strength, and low granule forming rate, and achieve low energy consumption, increased output, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

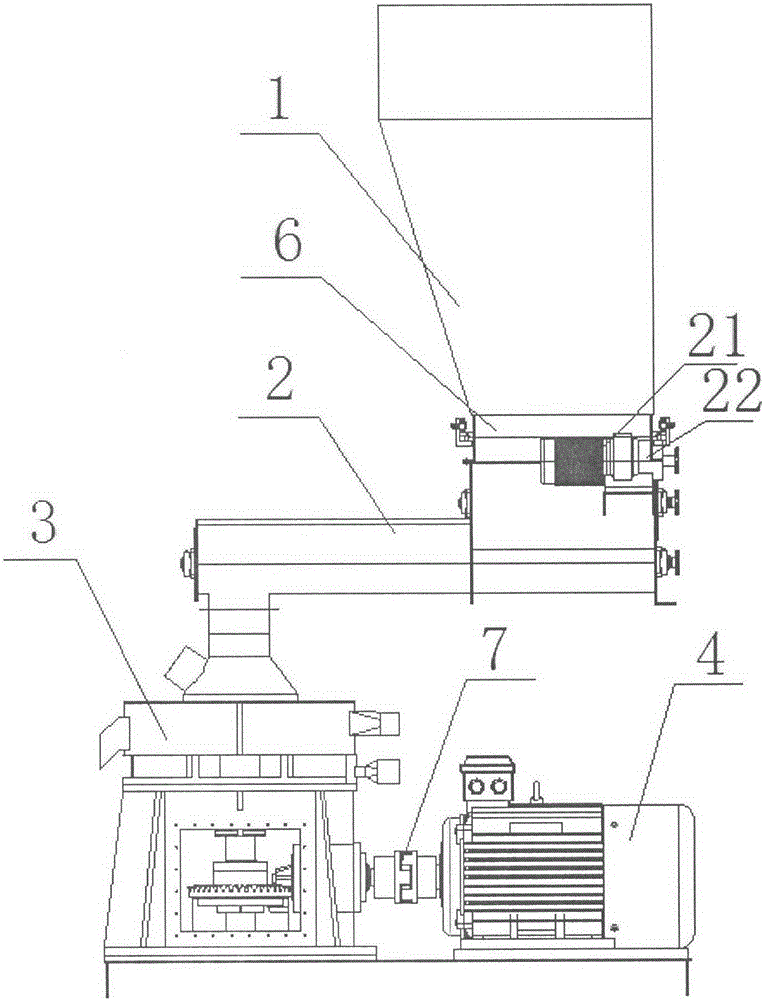

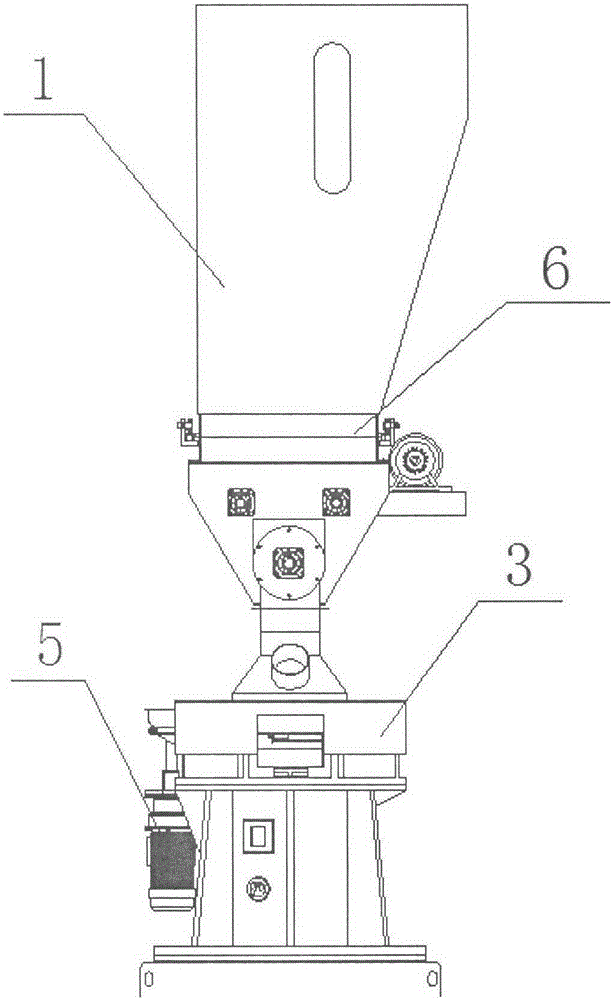

[0025] Such as Figure 1-2 As shown, a granulator, which is fixed on the base, includes a bin to be granulated 1, a feeder 2, a pressing device 3, a main motor 4 and a distribution motor 5,

[0026] The lower end of the bin 1 to be granulated is connected to the feed port of the feeder 2 through a movable connection mechanism 6; the discharge port of the feeder 2 is softly connected to the feed port of the pressing device 3; the main motor 4 passes The elastic coupling 7 is connected with the pressing device 3 ; the distribution motor 5 is arranged on the side wall of the pressing device 3 .

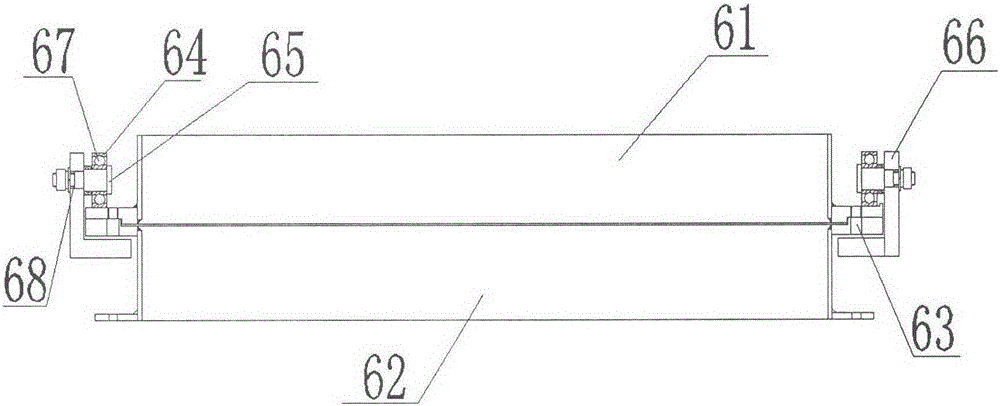

[0027] Such as image 3 As shown, the movable connection mechanism is divided into a fixed part 61 and a movable part 62. The fixed part 61 is welded to the bin 1 to be granulated, and the movable part 62 is connected to the feeder 2 through bolts; the movable connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com