Anti-corrosion nested type gear and gear pump filling machine

A corrosion-resistant, nested technology, used in portable lifting devices, belts/chains/gears, hoisting devices, etc., can solve the problems of easy corrosion, difficult to repair, poor gear replacement, etc., to achieve cost reduction, not easy to rust , High wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

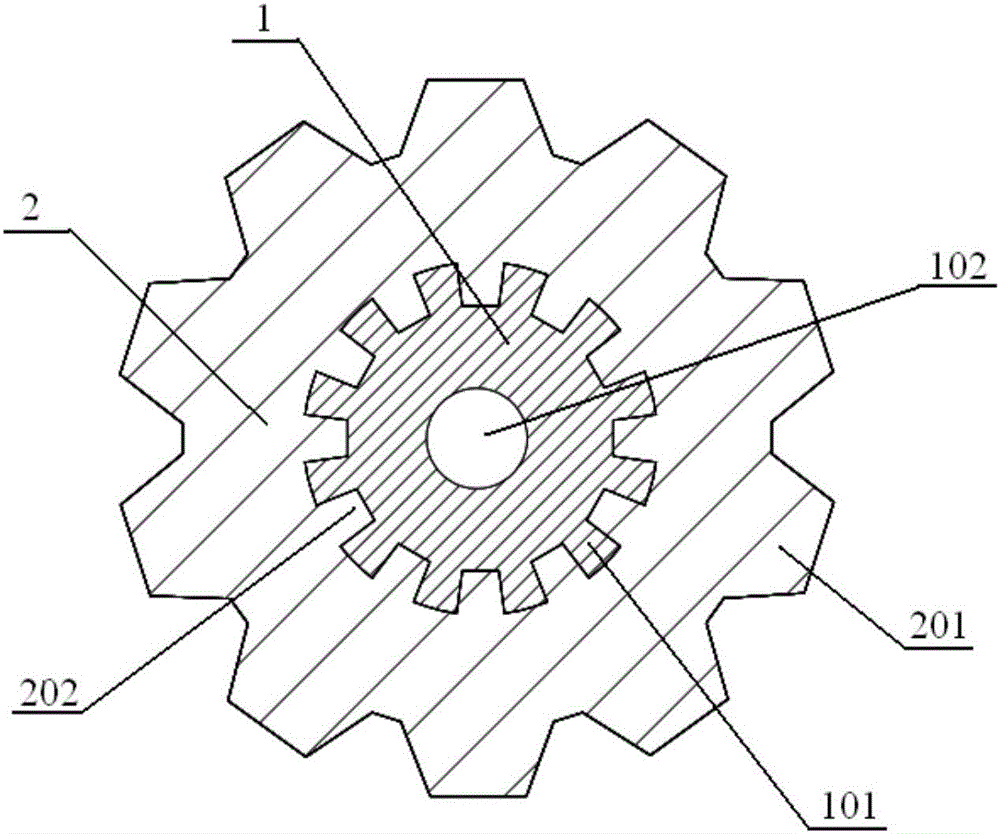

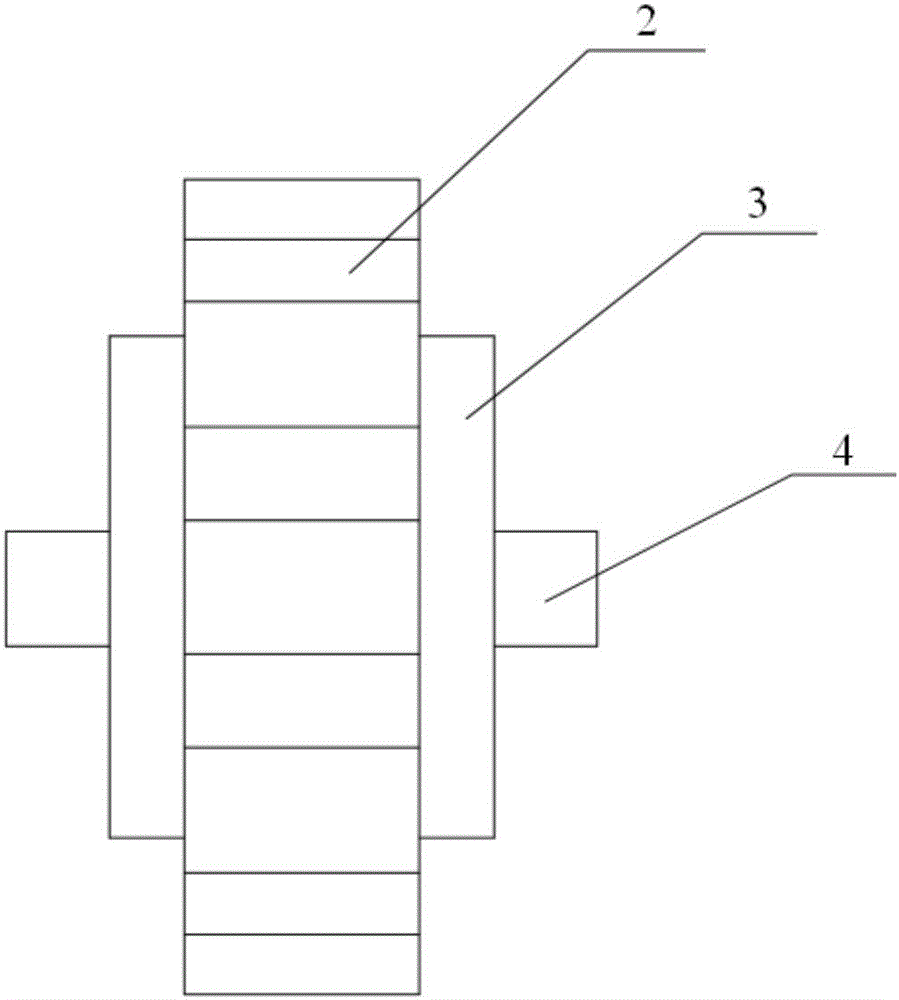

[0032] The corrosion-resistant nested gear and gear pump filling machine described in this embodiment includes an inner ring gear 1 and an outer ring gear 2 . Such as figure 1 , figure 2 As shown, the outer ring gear 2 is nested outside the inner ring gear 1; the center of the inner ring gear 1 is provided with a shaft hole 102; the outer peripheral surface of the outer ring gear 2 is provided with a plurality of first teeth Teeth 201;

[0033] The outer ring gear 2 described in this embodiment is made of corrosion-resistant plastic material, specifically, novolac epoxy vinyl ester resin (Novolac vinyl ester resin), polyparaphenylene terephthalamide (PPA), polytetrafluoroethylene One of (PTFE) and polyether ether ketone (PEEK).

[0034] The inner ring gear 1 described in this embodiment is made of low-alloy structural steel, specifically one of the grades of 20CrMnTi, 20CrMo, 20CrMnMo, 30CrMnTi, 30CrMnSi and 22CrMoH steel; wherein, Cr-chromium, Mn-manganese, Ti-titanium, ...

Embodiment 2

[0040] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

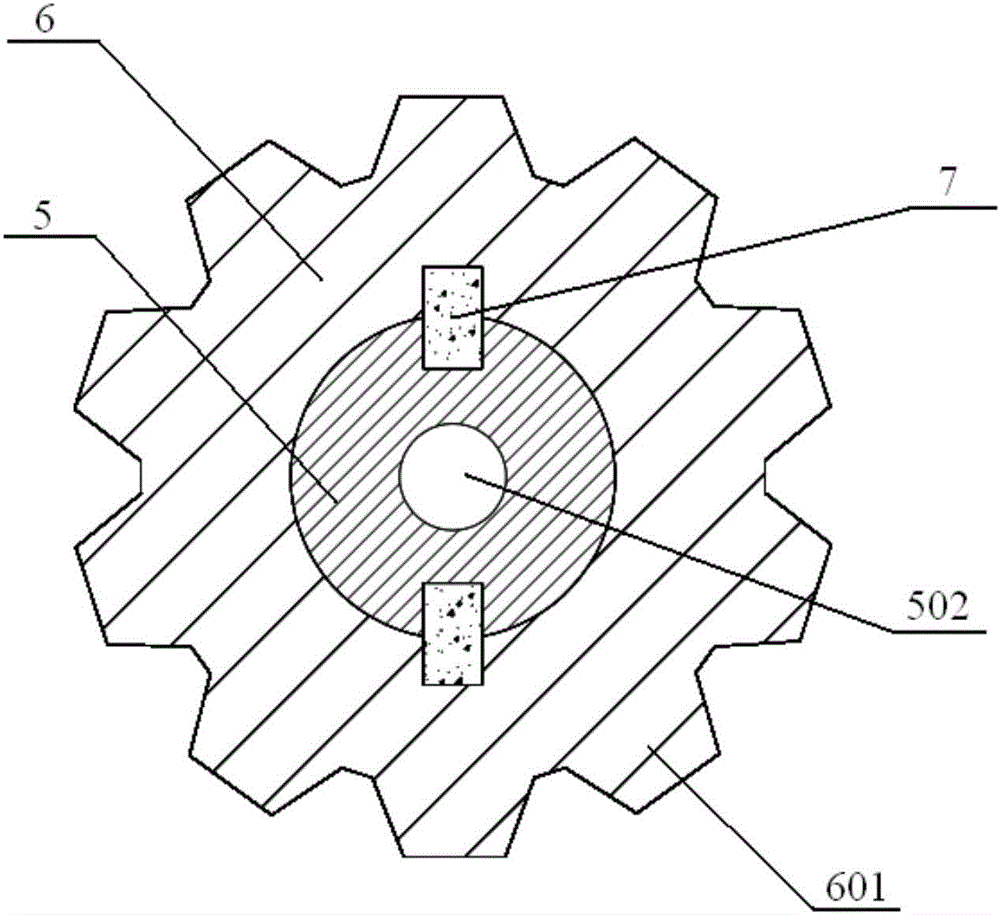

[0041] The corrosion-resistant nested gear and gear pump filling machine described in this embodiment, such as image 3 and Figure 4 As shown, it includes an inner ring gear 5 and an outer ring gear 6 . The outer ring gear 6 is nested outside the inner ring gear 5; the center of the inner ring gear 5 is provided with a shaft hole 502; the outer peripheral surface of the outer ring gear 2 is provided with a plurality of first teeth 601;

[0042] The connection mode between the inner ring gear 5 and the outer ring gear 6 in this embodiment is specifically as follows:

[0043] Such as image 3 As shown, the end face of the inner ring gear 5 and the end face of the outer ring gear 6 are provided with cuboid square hole slots that can communicate with each other, and a centrally symmetrical pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com