Lightweight environment-friendly smokeless thermal insulation material for household appliances

A thermal insulation material and environmentally friendly technology, which is applied in the direction of layered products, glass/slag layered products, synthetic resin layered products, etc. Problems such as poor performance, to achieve the effect of light weight, low bulk density and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

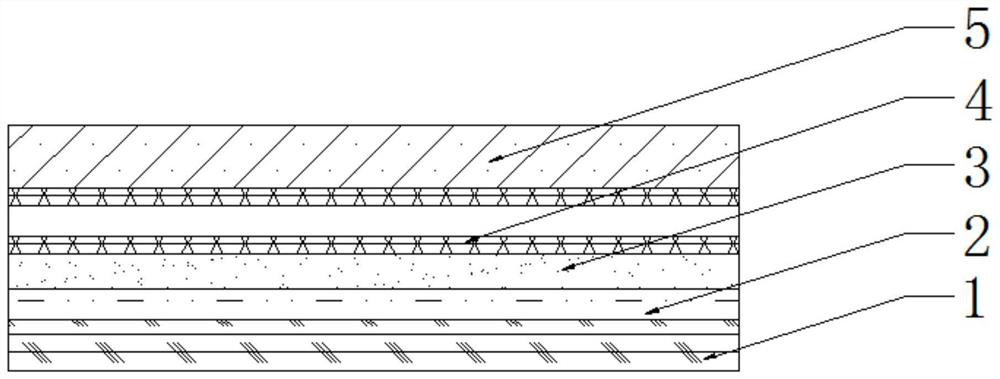

[0033] see figure 1 , the present invention provides a technical solution: a light-weight and environment-friendly heat preservation material for smokeless household appliances, comprising a base material layer 1 and a heat preservation layer 6, an anti-corrosion cloth layer 2 is fixed on the upper side of the base material layer 1, and the anti-corrosion cloth layer 2 A flame-retardant layer 3 is fixed on the upper side, and a reinforcing net 4 is fixed above the flame-retardant layer 3 , and a sound-insulating layer 5 is arranged between the reinforcing nets 4 , and a thermal insulation layer 6 is fixed on the top of the reinforcing net 4 . The reinforcing net 4 is provided with a double-layer structure, and the thicknesses between the reinforcing nets 4 are the same.

[0034] The light-weight, environment-friendly smokeless home appliance insulation material includes the following processing steps:

[0035] A. Material selection;

[0036] B. Material preparation;

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com