High-entropy alloy composition, high-entropy alloy thin film and preparation method of high-entropy alloy target material and thin film

A high-entropy alloy and composition technology, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the requirements of mechanical properties that are difficult to meet, the application prospect of high-entropy alloys is unclear, and the preparation of high-entropy alloys The theoretical system is not perfect and other problems, to achieve the effect of improving performance, reducing defects, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a method for preparing a high-entropy alloy target, comprising vacuum melting the above-mentioned high-entropy alloy composition to prepare a high-entropy alloy target. Of course, the vacuum smelting method here can be operated in a manner understandable by those skilled in the art, as long as each metal can be smelted uniformly to form an alloy.

[0052] The present invention also provides a method for preparing a high-entropy alloy thin film. In a further preferred embodiment, in order to ensure the performance of the high-entropy alloy thin film, it is further selected that the above-mentioned high-entropy alloy target is subjected to magnetron sputtering, High-entropy alloy thin films were prepared.

[0053] In a more preferred embodiment, the magnetron sputtering can be further defined as DC magnetron sputtering, such as Figure 10 As shown, the DC magnetron sputtering specifically includes:

[0054] S100. Place the substrate a...

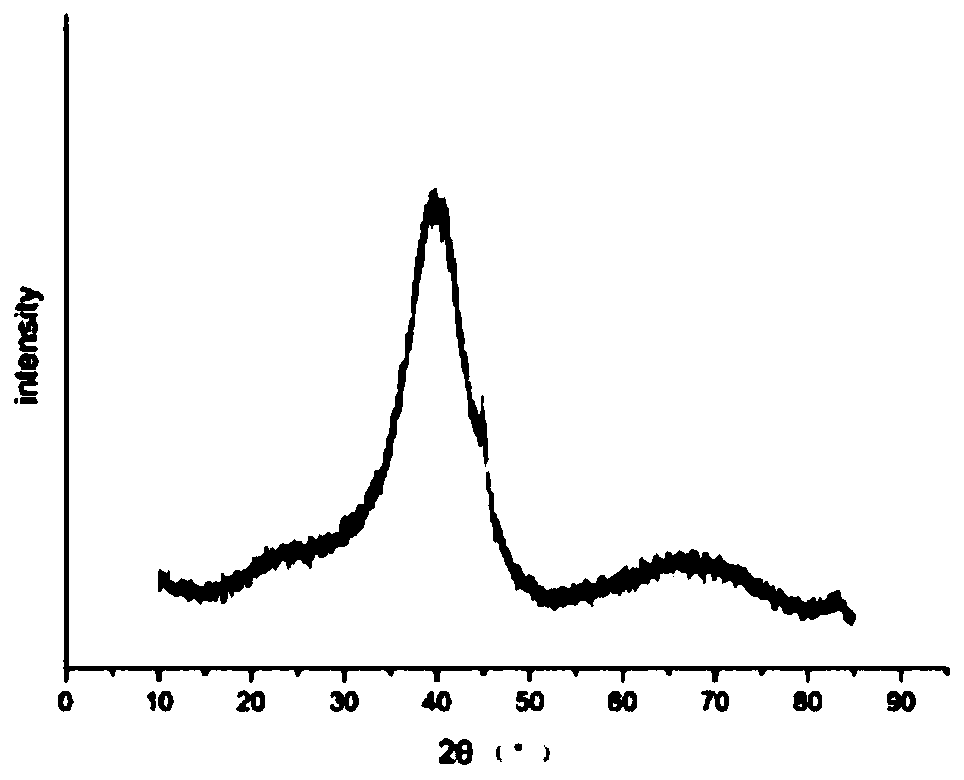

Embodiment 1

[0068] 1) Weighing Al, Cr, Ti, Gd, Zr raw materials with a material ratio of 1:1:1:1:1, and using a vacuum casting method to prepare a high-entropy alloy target;

[0069] 2) Wash the substrate in acetone, deionized water, and absolute ethanol for 10 minutes respectively, and place it in a magnetron sputtering vacuum chamber facing the target 10 cm after drying;

[0070] 3) After the mechanical pump is vacuumed to a vacuum degree of 10Pa, turn on the molecular pump to pump a vacuum to a vacuum degree of 5×10 -3 Pa, flow argon gas at a flow rate of 80sccm, adjust the partial pressure valve to make the vacuum degree reach 1.0Pa, turn on the bias power supply, increase the bias voltage to -900V, and perform glow cleaning on the substrate for 10min; then turn off the bias power supply , adjust the partial pressure valve so that the vacuum degree is 0.5Pa, the sputtering current is 0.7A, and the high-entropy alloy target is sputtered and cleaned for 5 minutes;

[0071] 4) Open the ...

Embodiment 2

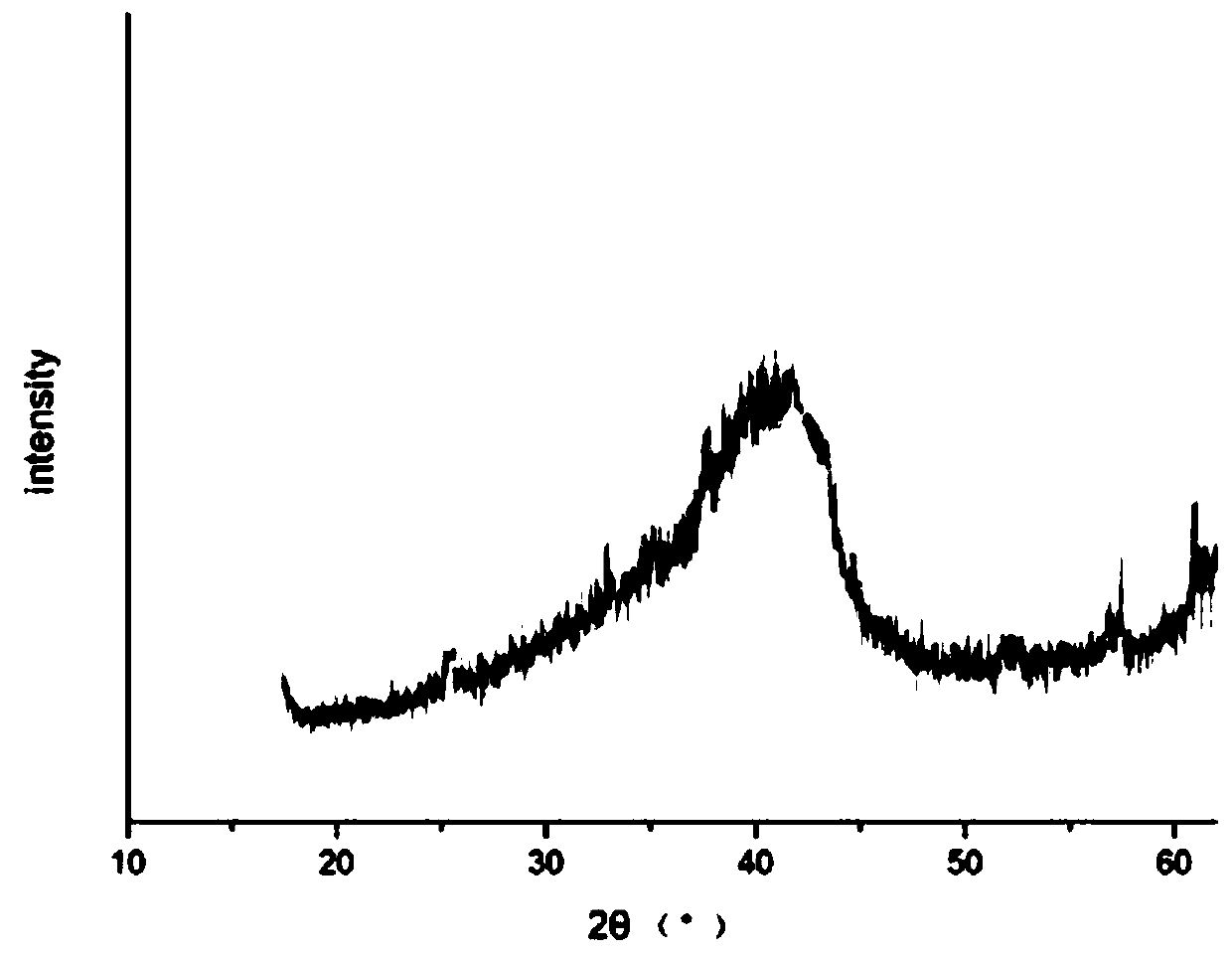

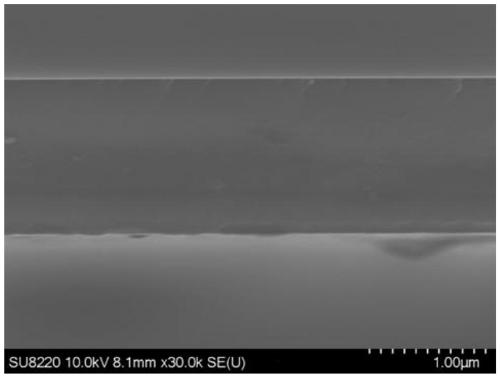

[0074] Prepare according to the method of Example 1, the difference is that the ratio of the amount of substance of Al, Cr, Ti, Gd, Zr raw materials is 2:2:1:1:1, and the sputtering current in step 4) is 0.8A , the sputtering time is 1.5h, and the high-entropy alloy thin film A2 is obtained. (the XRD collection of A2 obtained at room temperature is as Figure 7 , showing an amorphous structure; SEM at room temperature as Figure 8 As shown, it presents a compact, smooth and defect-free cross-sectional morphology; the nanohardness of A2 is as follows Figure 9 As shown, it can be seen that its hardness is as high as 13Gpa or more, which has very good hardness. )

[0075] The invention can conveniently convert the cast AlCrTiGdZr high-entropy alloy into an amorphous AlCrTiGdZr high-entropy alloy thin film through the method of magnetron sputtering. At the same time, it can be further seen from the above examples and characterization diagrams that the prepared high-entropy al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com