Near-beta type titanium alloy with good matching of strength and plasticity and preparation method thereof

A technology of titanium alloy and plasticity, which is applied in the field of near-β-type titanium alloy and its preparation, can solve the problems of high cost and cumbersome process, and achieve good plasticity, optimized strength and plasticity matching, and remarkable effect of solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares nearly β type titanium alloy and comprises the following steps:

[0027] Step 1, adopt powder metallurgy method to prepare nearly β type titanium alloy ingot, the composition of near β type titanium alloy ingot is, by mass percentage, 5%Al, 5%Mo, 5%V, 3%Cr and 0.36% O, the rest is Ti and unavoidable impurities. After the alloy ingot is upset and forged, it is rolled into a φ11.5mm bar;

[0028] Step 2: heating the alloy bar at 600° C. for 1 hour, and then air cooling to room temperature to obtain a nearly β-type titanium alloy with good matching of strength and plasticity.

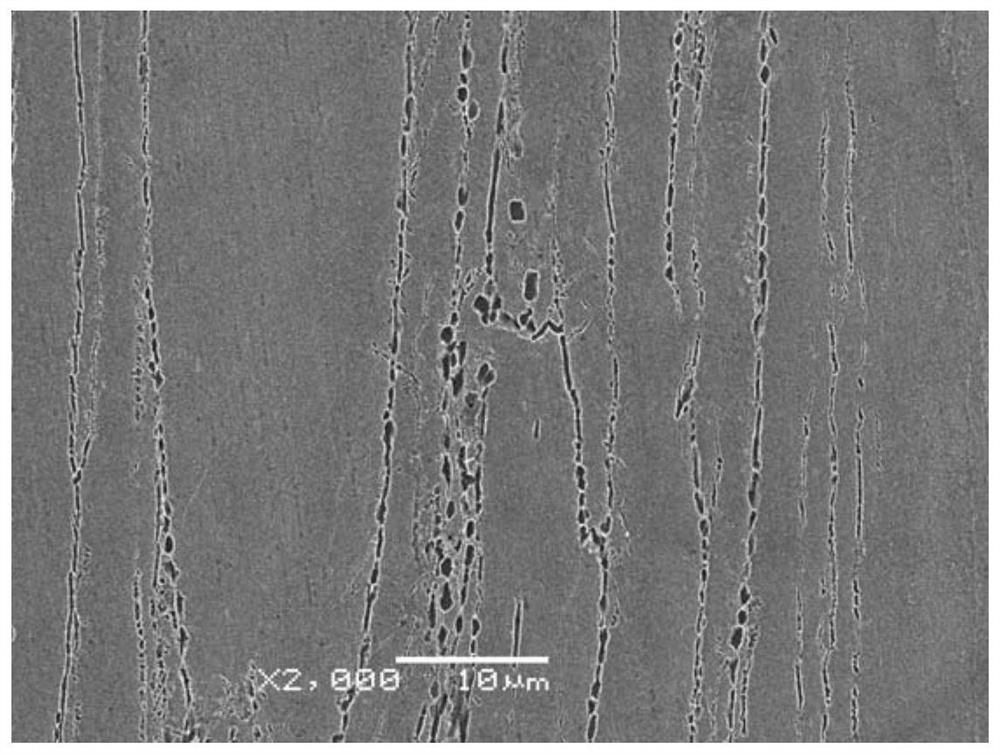

[0029] see figure 1 , figure 1 It is the microstructure figure of the near β type titanium alloy after the heat treatment of embodiment 1 from figure 1 It can be seen that the alloy exhibits the characteristics of layered heterogeneous multi-level second phase structure after heat treatment. Among them, the heterogeneous mixed crystals include ultrafine β grains and coarser...

Embodiment 2

[0032] Embodiment 2 prepares nearly β type titanium alloy and comprises the following steps:

[0033] Step 1, adopt powder metallurgy method to prepare alloy ingot of nearly β type titanium alloy, the composition of near β type titanium alloy ingot is, by mass percentage, 5% Al, 5% Mo, 5% V, 3% Cr and 0.36% O, the rest is Ti and unavoidable impurities; after the alloy ingot is upset and forged, it is rolled into a φ11.5mm bar;

[0034] Step 2: Heat the alloy bar at 630° C. for 1 hour, and then cool it to room temperature in air to obtain a nearly β-type titanium alloy with good matching of strength and plasticity.

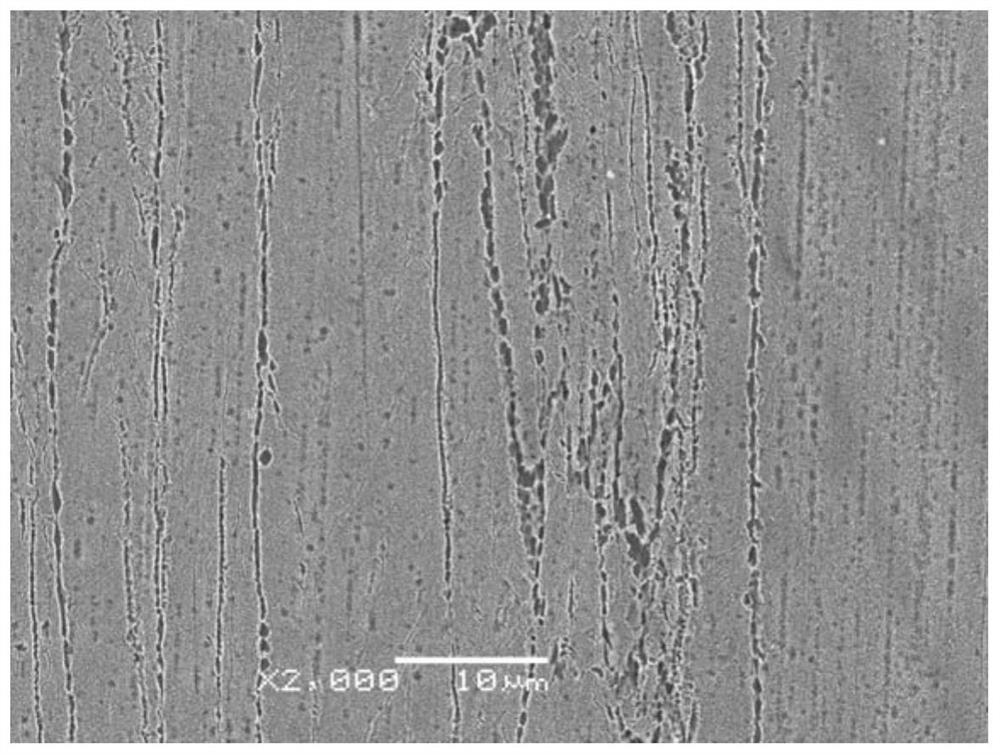

[0035] see figure 2 , figure 2 Be the microstructure diagram of the near β type titanium alloy after the heat treatment of embodiment 2, from figure 2 It can be seen that the alloy exhibits the characteristics of layered heterogeneous multi-level second phase structure after heat treatment. Among them, the heterogeneous mixed crystals include ultrafine β gra...

Embodiment 3

[0038] Embodiment 3 prepares nearly β type titanium alloy and comprises the following steps:

[0039] Step 1, adopt powder metallurgy method to prepare alloy ingot of nearly β type titanium alloy, the composition of near β type titanium alloy ingot is, by mass percentage, 5%Al, 5%Mo, 5%V, 3%Cr and 0.36% O, and the rest is Ti and unavoidable impurities. After the alloy ingot is upset and forged, it is rolled into a φ11.5mm bar;

[0040] Step 2: Heat the alloy bar at 660° C. for 1 hour, and then cool it to room temperature in air to obtain a near-β-type titanium alloy with a good match between strength and plasticity.

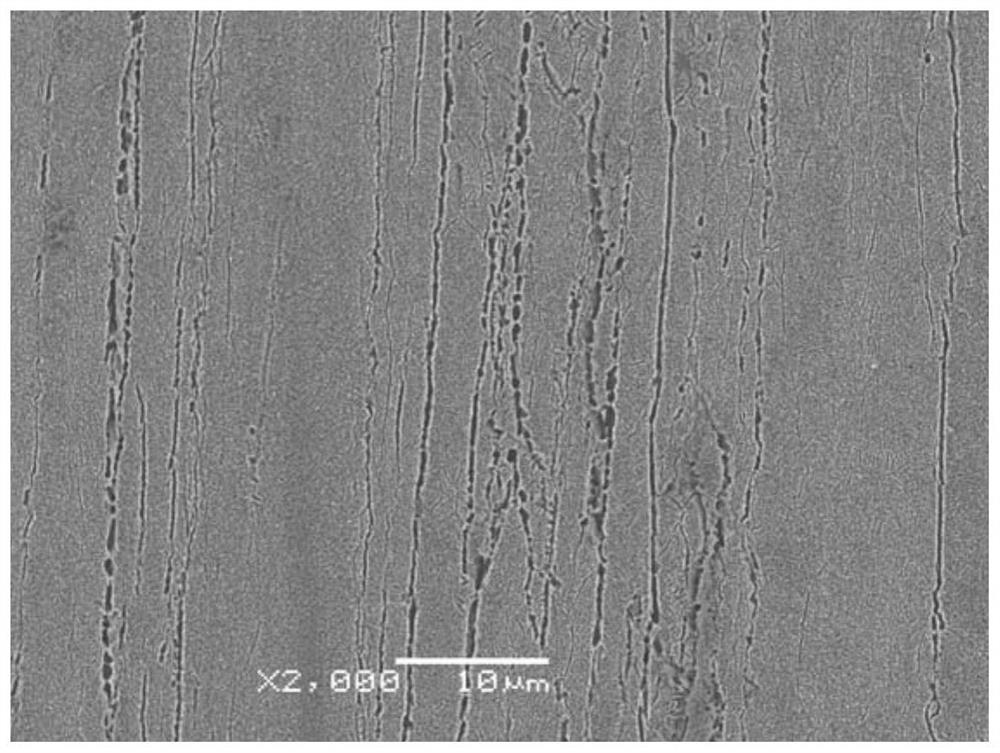

[0041] see image 3 , image 3 Be the microstructural figure of the nearly β type titanium alloy after the heat treatment of embodiment 3, from image 3It can be seen that the alloy exhibits the characteristics of layered heterogeneous multi-level second phase structure after heat treatment. Among them, the heterogeneous mixed crystals include ultrafine β gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com