Thermoplastic elastomer material for secondary overmolding with polyketone material and preparation method thereof

A technology of thermoplastic elastomer and secondary injection bonding, which is applied in the chemical industry, can solve the problems of lack of texture and touch comfort, and achieve good weather resistance, high tensile strength and elongation at break, and excellent temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a further description of the present invention through specific examples. It must be pointed out that the following examples are only further descriptions of the present invention, rather than limiting the scope of the present invention, and some non-essential improvements and adjustments made by those skilled in the art based on the contents of the present invention above still belong to the present invention. protection scope of the invention.

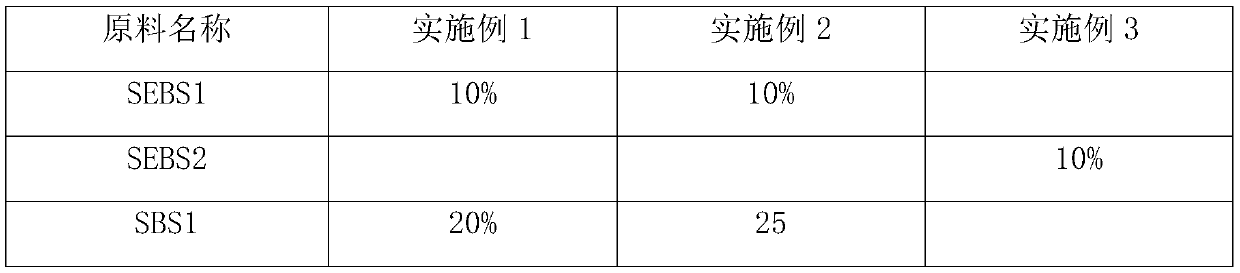

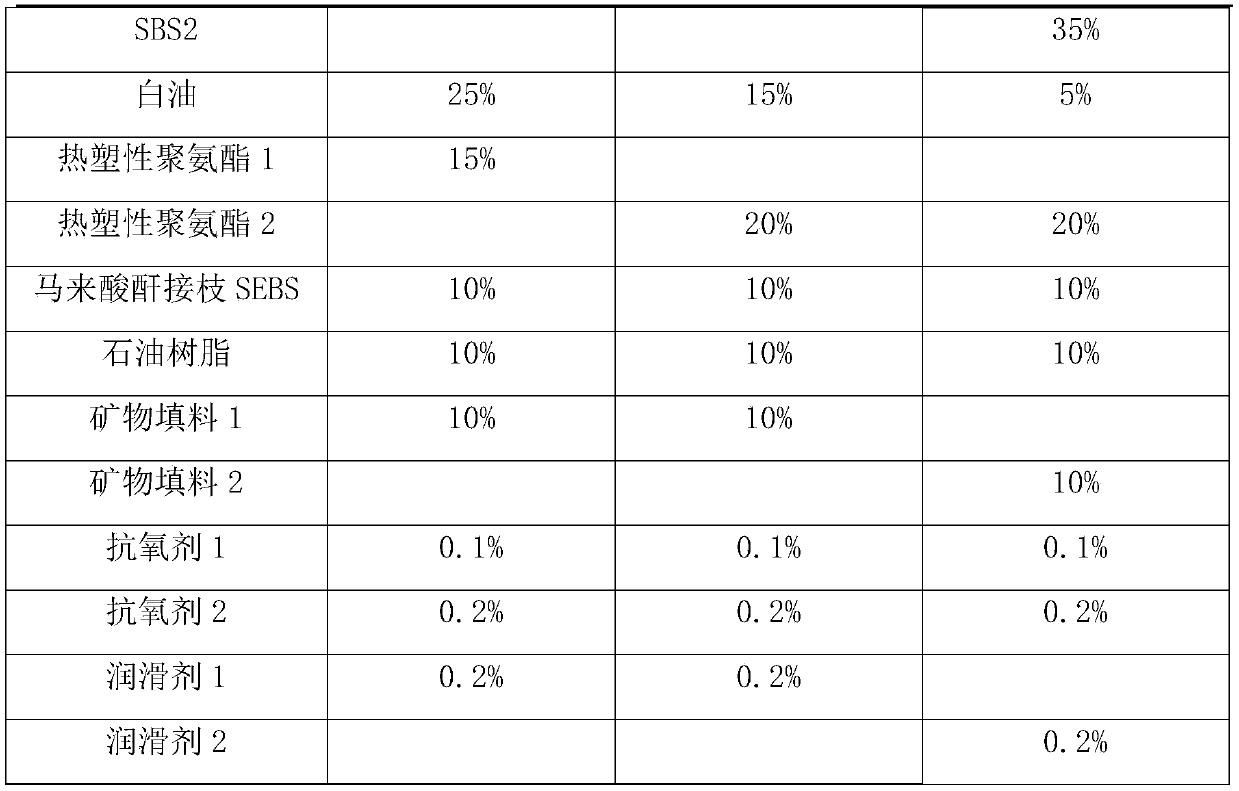

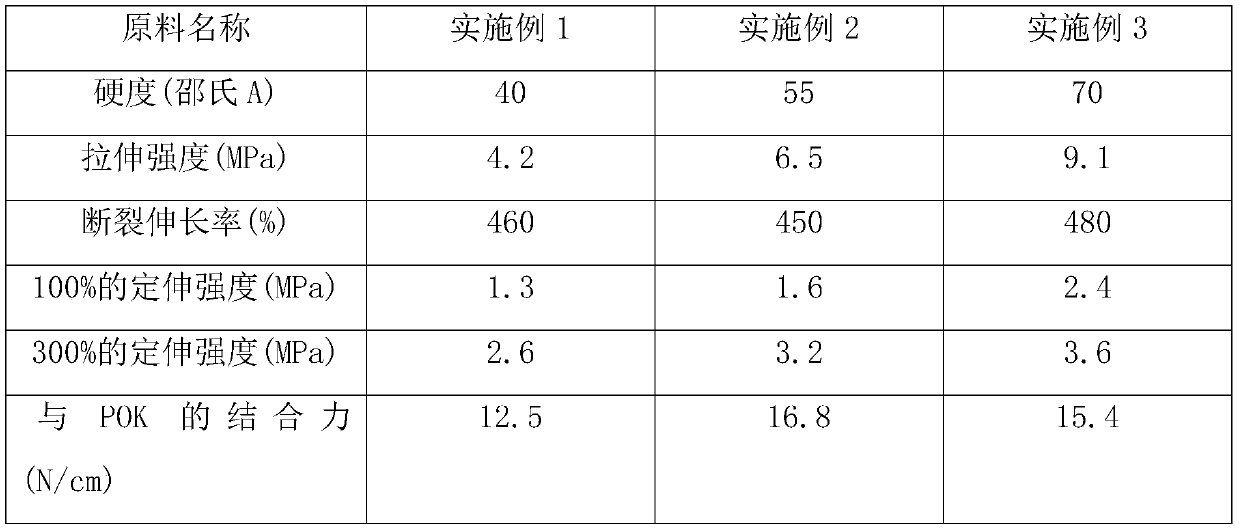

[0031] The component formula of embodiment

[0032]

[0033]

[0034] Note, each component in the embodiment is introduced as follows:

[0035] SEBS1: Model G1651, American Kraton Company, the monomer ratio of styrene and rubber is 33 / 67, and the hardness is 61A.

[0036] SEBS2: Model 7550, Taiwan Li Changrong Chemical Industry Co., Ltd., 30% styrene content, 67A hardness.

[0037] SBS1: Model D1155, American Kraton Company, the monomer ratio of styrene and rubber is 40 / 60, and the hardness is 87A.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com