Improved rubber composite environment-friendly rubber floor and manufacturing method

An environmentally friendly rubber and floor technology, applied in the direction of rubber layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of poor wear resistance of PVC floors, substandard environmental protection, affecting physical safety, etc., and achieve good elasticity. , cheap, and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment discloses an improved rubber-plastic composite environment-friendly rubber floor, which includes a surface layer, a transition layer and a bottom layer in sequence from top to bottom, and the surface layer, transition layer, and bottom layer are pressed together by high temperature.

[0020] Wherein, the surface layer is vulcanized rubber, comprising the following components by mass: styrene-butadiene rubber 50-80, natural rubber 0-30, chlorinated polyethylene rubber 20-40, zinc oxide 4-8, stearic acid 4 -10, Accelerator 3-6, Antiaging Agent 2-4, Silica 20-40, Kaolin 30-50, Flame Retardant 50-80, Sulfur 2-5 and Pigment 2-10.

[0021] In this embodiment, in order to improve the compression deformation resistance, aging resistance, wear resistance and anti-skid properties of the rubber floor surface layer, the accelerators are thiurams and thiazoles, and the flame retardants are inorganic flame retardants , Anti-aging agent is phenolic anti-aging agent. P...

Embodiment 2

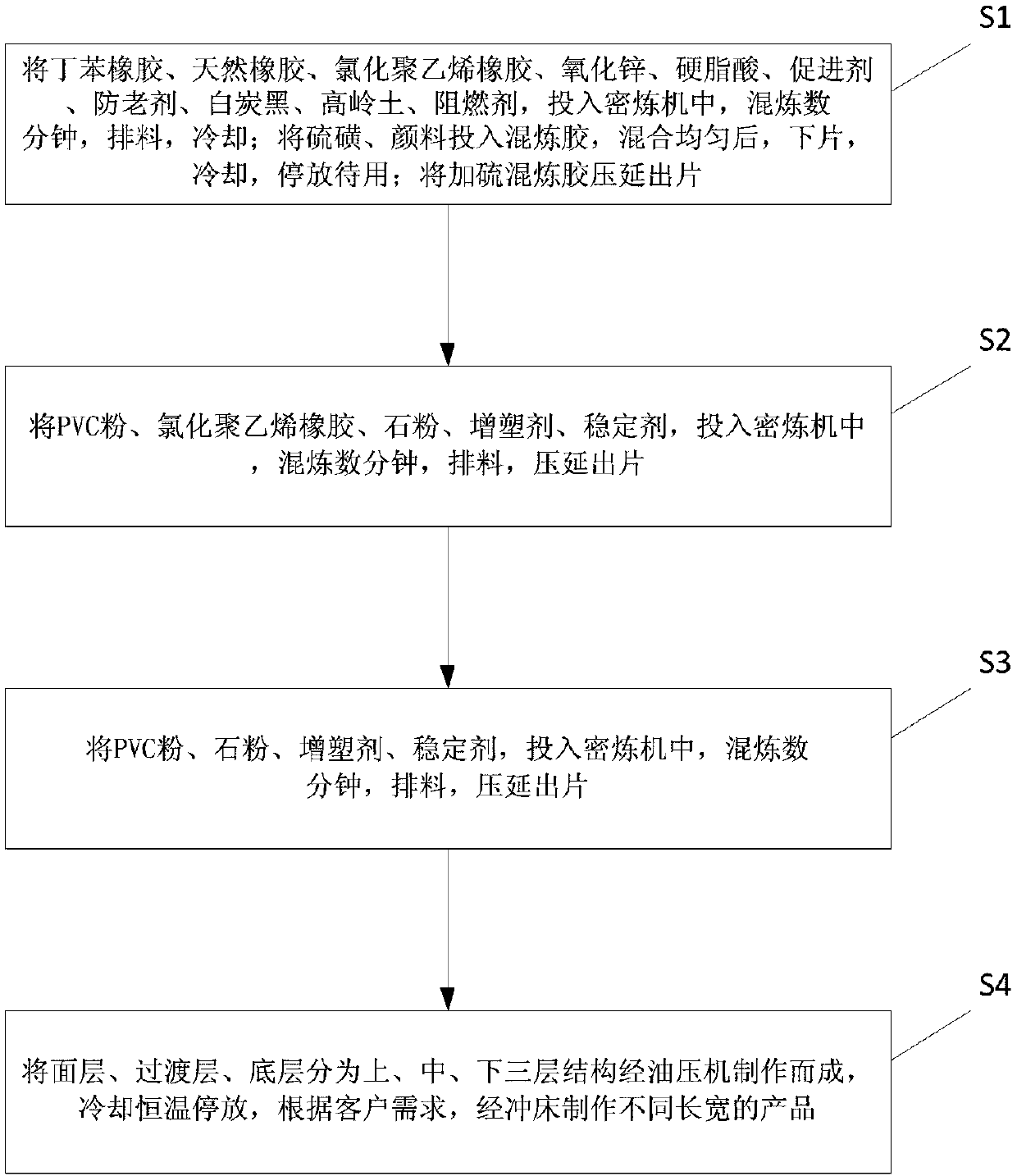

[0025] This embodiment discloses a manufacturing method of an improved rubber-plastic composite environmental-friendly rubber floor, which specifically includes the following steps:

[0026] In the first step, styrene-butadiene rubber 50-80, natural rubber 0-30, chlorinated polyethylene rubber 20-40, zinc oxide 4-8, stearic acid 4-10, accelerator 3-6, antioxidant 2-4 , white carbon black 20-40, kaolin 30-50, flame retardant 50-80, put into the internal mixer, knead for 10-20 minutes, discharge, cool; put sulfur 2-5, pigment 2-10 into the mixing After mixing the rubber evenly, the film is released, cooled, and parked for use; the vulcanized mixed rubber is calendered and rolled out, the thickness and width can be customized according to actual needs, the thickness can reach 0.5-3.0mm, and the width can reach 0.5-2.0m , the length can reach 0.5-2.0m;

[0027] In the second step, put PVC powder 80-100, chlorinated polyethylene rubber 80-100, stone powder 100-150, plasticizer 10-...

Embodiment 3

[0031] This embodiment discloses a manufacturing method of an improved rubber-plastic composite environmental-friendly rubber floor, which specifically includes the following steps:

[0032] In the first step, 39kg of styrene-butadiene rubber, 21kg of chlorinated polyethylene rubber, 3.6kg of zinc oxide, 3.3kg of stearic acid, 2.4kg of accelerator, 2.4kg of antioxidant, 21kg of white carbon black, 18kg of kaolin, and 42kg of flame retardant, Put it into the internal mixer, mix for 17 minutes, discharge, and cool; put 1.2kg of sulfur and 1.6kg of pigment into the rubber compound, mix evenly, remove the tablet, cool it, and park it for use; calender the sulfur-added rubber compound Sheet, thickness 1.2mm, width 1.1m, length 1.1m;

[0033] In the second step, 48kg of PVC powder, 48kg of chlorinated polyethylene rubber, 60kg of stone powder, 12kg of plasticizer, and 1.0kg of stabilizer are put into the internal mixer, mixed for 3.5 minutes, discharged, calendered, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com