Acrylic rubber composition, vulcanizate, hose part, and sealing part

A rubber composition, acrylic technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of insufficient compression set, poor extrudability, insufficient mechanical properties, etc., and achieve good processing safety and sufficient Excellent mechanical properties and compression set resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

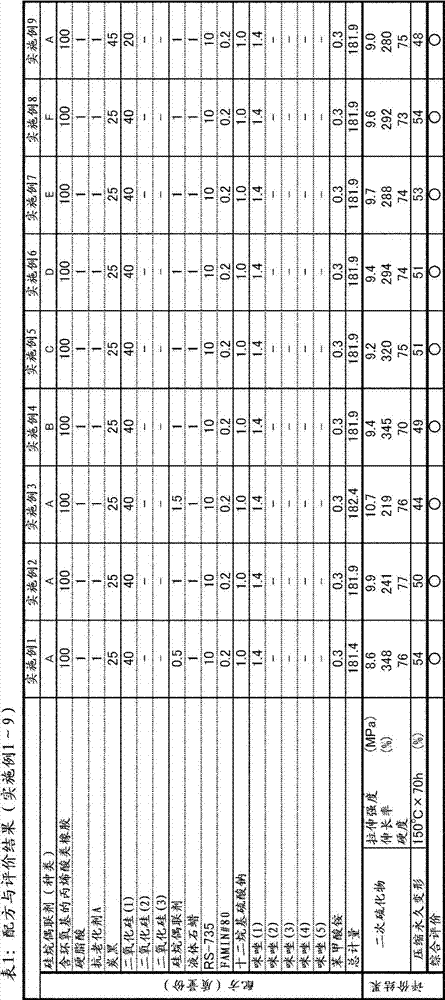

Embodiment 1

[0067] 2.7g stearic acid, 2.7g anti-aging agent A, 67.5g carbon black, 108g silicon dioxide (1), 0.5g stearamide, 2.7g liquid paraffin, 1.4g 3-ring Oxypropoxypropyldimethoxymethylsilane and 27 g of a plasticizer were kneaded in 270 g of the thus obtained acrylic rubber. 3.8 g of 1-cyanoethyl-2-methylimidazole, 0.8 g of ammonium benzoate, and 2.7 g of sodium lauryl sulfate were added to the obtained composition, and kneaded using an 8-inch open mill to obtain an acrylic rubber combination. The obtained acrylic rubber composition was heat-treated at 170° C. for 20 minutes with an electric heating type hot press, and then heat-treated with a Jill thermal aging test box at 170° C. for 4 hours to obtain Vulcanizates of acrylic rubber compositions.

Embodiment 2

[0069] An acrylic rubber composition was obtained in the same manner as in Example 1, except that 2.7 g of 3-glycidoxypropyldimethoxymethylsilane was added.

Embodiment 3

[0071] An acrylic rubber composition was obtained in the same manner as in Example 1, except that 4.1 g of 3-glycidoxypropyldimethoxymethylsilane was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com