Acrylic rubber

A technology of acrylic rubber and olefin, applied in the field of acrylic rubber, can solve the problem of insufficient improvement of compression set resistance and achieve good results in normal physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

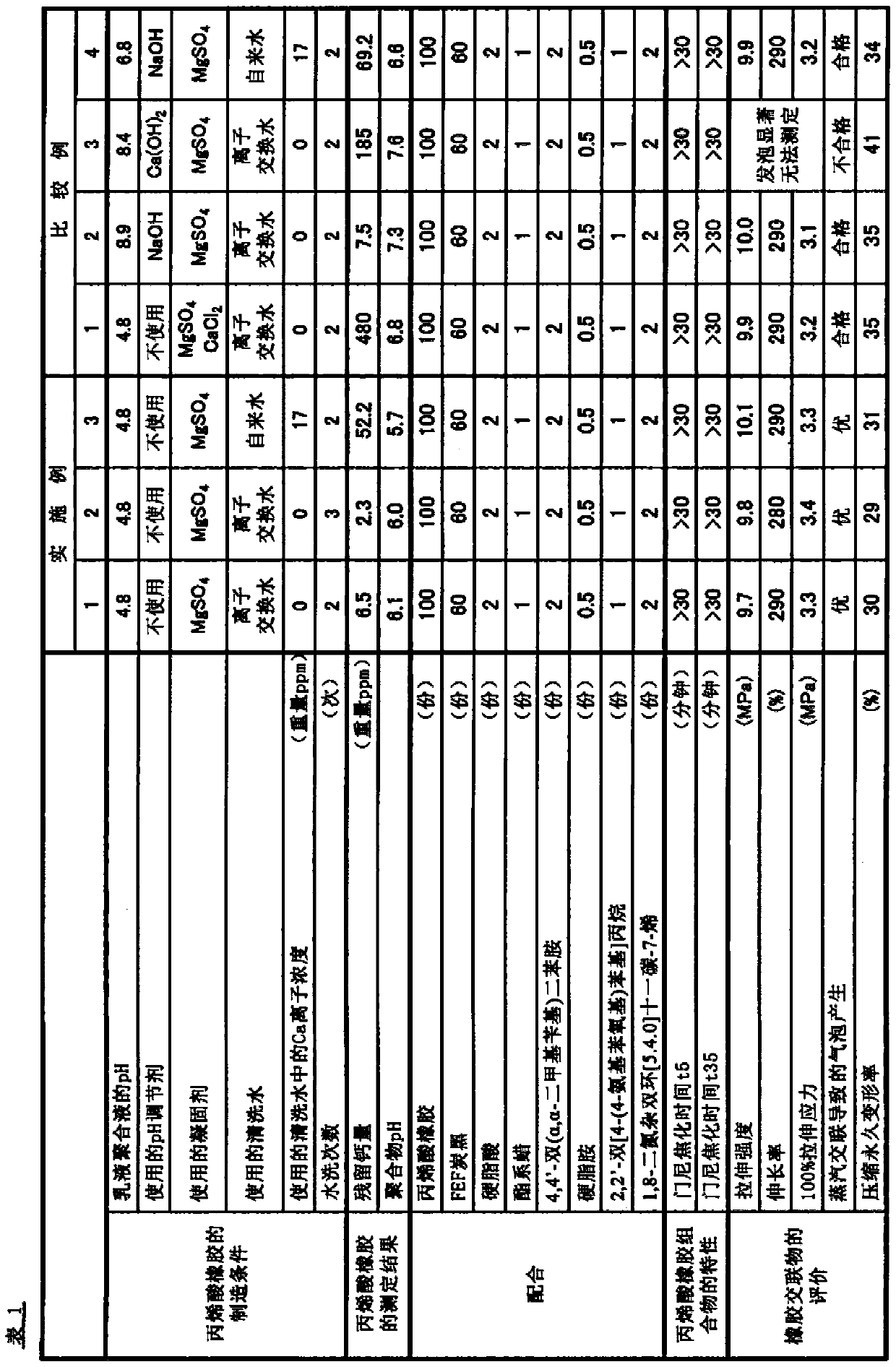

[0131] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples. In addition, unless otherwise specified, "parts" in each example are based on weight.

[0132] Various physical properties were evaluated according to the following methods.

[0133] [Residual Calcium Amount]

[0134]Sulfuric acid and nitric acid were added to acrylic rubber, heated to perform wet decomposition, and then diluted appropriately to obtain a sample. Using the obtained sample, an ICP-AES device (SPS-5000: manufactured by Seiko Instruments Inc. ), the amount of calcium ions was measured by the internal standard standard curve method, thus obtaining the amount of residual calcium.

[0135] [Polymer pH]

[0136] The polymer pH of the acrylic rubber was measured according to the following procedure. That is, first, an acrylic rubber is formed into a sheet using a roller, the sheet-shaped acrylic rubber is cut into pieces with scissors, and 6...

manufacture example 1

[0149] In the polymerization reactor with thermometer, stirring device, nitrogen introduction pipe and decompression device, add 200 parts of pure water, 69.8 parts of ethyl acrylate, 29.0 parts of n-butyl acrylate, 1.2 parts of fumaric acid mono-n Butyl ester, 2.4 parts of sodium lauryl sulfate (trade name "Emal 2FG", manufactured by Kao Corporation.) as a surfactant. Then, degassing and nitrogen replacement based on decompression were repeated, and after oxygen was fully removed, 0.00014 parts of sodium formaldehyde sulfoxylate and 0.25 parts of p-terpane hydroperoxide were added to start emulsion polymerization at normal pressure and temperature. , continue the reaction until the polymerization conversion rate reaches 95%, thus obtaining the emulsion polymerization liquid. The pH of the obtained emulsion polymerization solution was 4.8, and the solid content concentration was 32% by weight.

[0150] Then, the obtained emulsion polymerization solution was transferred to a c...

manufacture example 2

[0154] A solid acrylic rubber (A2) was obtained in the same manner as in Production Example 1 except that the number of water washings of the coagulated water-containing aggregate was changed from 2 times to 3 times. The composition of the obtained acrylic rubber (A2) was 69.8% by weight of ethyl acrylate unit, 29% by weight of n-butyl acrylate unit, and 1.2% by weight of mono-n-butyl fumarate unit. In addition, the residual calcium content of the acrylic rubber (A2) was 2.3 ppm by weight, and the polymer pH was 6.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com