Heat-curable polyurethane resin composition and urethane elastomer molded article using the same

A polyurethane resin and polyurethane prepolymer technology, which is applied in the field of polyurethane elastomer moldings, can solve the problems of deterioration of compression set resistance, difficulty in obtaining flame-retardant and low-hardness polyurethane elastomer moldings, etc., and achieve compression resistance Excellent permanent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

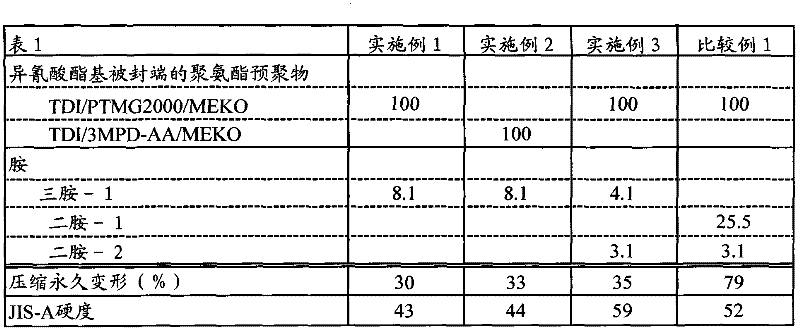

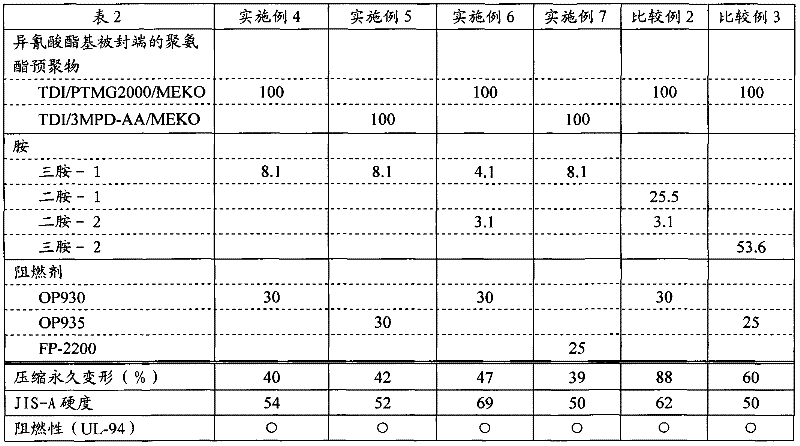

[0070] Hereinafter, the present invention will be explained in more detail through examples, but the scope of the present invention is not limited to these examples.

[0071] In addition, in the present invention, unless otherwise specified, "parts" are "parts by mass" and "%" are "mass%".

Synthetic example 1

[0072] Synthesis Example 1 Synthesis of polyurethane prepolymer (D-1) with blocked isocyanate groups

[0073] While stirring vigorously, add 74 parts of 2,4-toluene diisocyanate (NCO / OH = 1.7) to 500 parts of polytetramethylene ether glycol ("PTMG-2000" manufactured by Mitsubishi Chemical Corporation, number average molecular weight 2000) ), react at 100°C for 4 hours to obtain a polyurethane prepolymer.

[0074] This polyurethane prepolymer was cooled to 60°C, 31 parts of methyl ethyl ketoxime as a blocking agent was put into it, stirred at 70°C for 2 hours and reacted, thereby obtaining a polyurethane prepolymer with blocked isocyanate groups (D-1) . The obtained isocyanate group blocked polyurethane prepolymer (D-1) had a viscosity of 3800 mPa·s at 80°C.

Synthetic example 2

[0075] Synthesis Example 2 Synthesis of polyurethane prepolymer (D-2) with blocked isocyanate groups

[0076] While vigorously stirring, into 500 parts of liquid polyester diol (polyester diol obtained from 3-methylpentanediol and adipic acid, molecular weight 2000) was added 74 parts of 2,4-toluene diisocyanate (NCO / OH=1.7) and reacted at 100°C for 4 hours to obtain a polyurethane prepolymer.

[0077] This polyurethane prepolymer was cooled to 60°C, 31 parts of methyl ethyl ketoxime as a blocking agent was put into it, stirred at 70°C for 2 hours and reacted, thereby obtaining a polyurethane prepolymer with blocked isocyanate groups (D-2) . The obtained polyurethane prepolymer (D-2) in which the isocyanate group was blocked had a viscosity at 80°C of 4200 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com