High-abrasion resistance and high temperature-resistant cable sheath material

A technology of cable sheath and high temperature resistance, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor product stability, long service life, short service life, etc., and achieve good stability, long service life, high temperature resistance and The effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

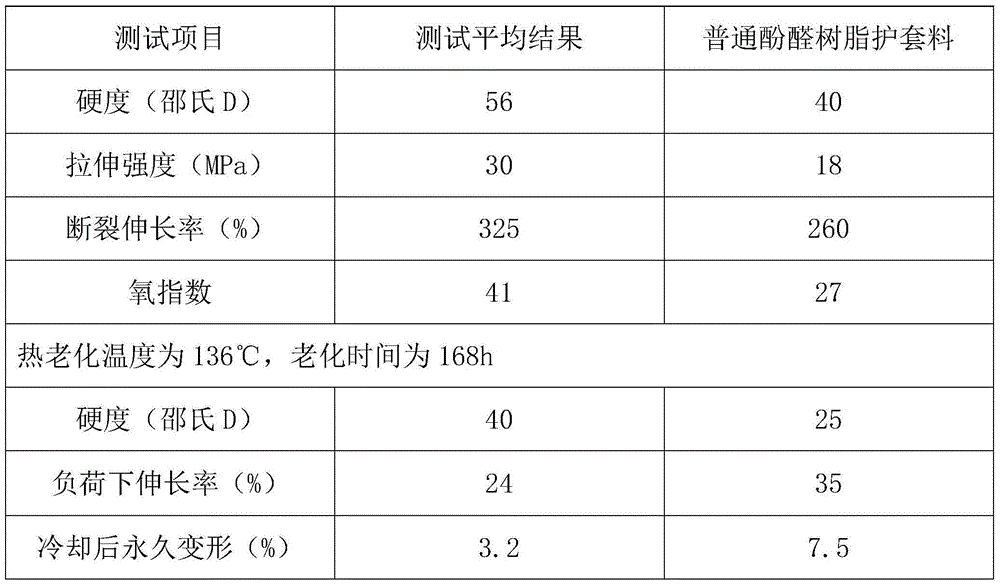

Examples

Embodiment 1

[0021] A kind of high abrasion and high temperature resistant cable sheath material proposed by the present invention, its raw material comprises by weight: 25 parts of modified phenolic resins, 35 parts of carboxylated nitrile rubbers, 30 parts of chlorohydrin rubbers, 1,1-bis-( 1.4 parts of tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.2 parts of sulfur powder, 0.8 parts of accelerator TMTM, 1.2 parts of accelerator CZ, 20 parts of magnesium oxide, furnace carbon black 30 parts, 30 parts of sepiolite powder, 10 parts of calcium silicate, 3 parts of trimellitate (n-octyl-n-decyl ester), 4 parts of epoxy butyl cottonseed oleate, 3 parts of anti-aging agent DFC-343 parts, anti-aging agent MBZ0. 5 copies;

[0022] In the preparation process of the modified phenolic resin, 0.02 parts of carbon nanotubes were dissolved in 2 parts of dimethylformamide by weight, soaked at room temperature for 3 days, ultrasonically treated for 20 minutes, filtered, washed, and sent into 0.05 part...

Embodiment 2

[0024] A kind of high wear-resistant and high-temperature-resistant cable sheath material proposed by the present invention, its raw material comprises by weight: 32 parts of modified phenolic resins, 27 parts of carboxylated nitrile rubber, 45 parts of chlorohydrin rubber, 1,1-bis-( 1 part of tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.35 parts of sulfur powder, 0.6 parts of accelerator TMTM, 1.4 parts of accelerator CZ, 12 parts of magnesium oxide, furnace carbon black 34 parts, 23 parts of sepiolite powder, 16 parts of calcium silicate, 1.5 parts of tris(n-octyl-n-decyl) trimellitate, 4.8 parts of epoxy butyl cottonseed oleate, 1.8 parts of anti-aging agent DFC-34, anti-aging agent MBZ1. 2 copies;

[0025] In the preparation process of the modified phenolic resin, 0.01 parts of carbon nanotubes were dissolved in 4 parts of dimethylformamide by weight, soaked at room temperature for 1.5 days, ultrasonically treated for 35 minutes, filtered, washed, and sent into 0.03 par...

Embodiment 3

[0027] A kind of high wear-resistant and high-temperature-resistant cable sheath material proposed by the present invention, its raw material comprises by weight: 30 parts of modified phenolic resins, 30 parts of carboxylated nitrile rubber, 40 parts of chlorohydrin rubber, 1,1-bis-( 1.1 parts of tert-butylperoxy)-3,3,5-trimethylcyclohexane, 0.3 parts of sulfur powder, 0.65 parts of accelerator TMTM, 1.32 parts of accelerator CZ, 15 parts of magnesium oxide, furnace carbon black 33 parts, 25 parts of sepiolite powder, 15 parts of calcium silicate, 2 parts of tris(n-octyl-n-decyl) trimellitate, 4.6 parts of epoxy butyl cottonseed oleate, 2 parts of anti-aging agent DFC-342 parts, 1 part of anti-aging agent MBZ ;

[0028] In the preparation process of the modified phenolic resin, 0.015 parts of carbon nanotubes were dissolved in 3.5 parts of dimethylformamide by weight, soaked at room temperature for 2 days, ultrasonically treated for 30 minutes, filtered, washed, and sent into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com