Thermoplastic vulcanizate elastomer composition and preparation method thereof

A rubber elastomer and thermoplastic vulcanization technology, which is applied in the field of thermoplastic vulcanized rubber elastomer composition and its preparation, can solve the problems of easy formation of mold scale, degradation of mechanical properties of materials, and influence on the service life of injection molded products, and achieve excellent surface effect, The production process is simple and easy, the effect of softness and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

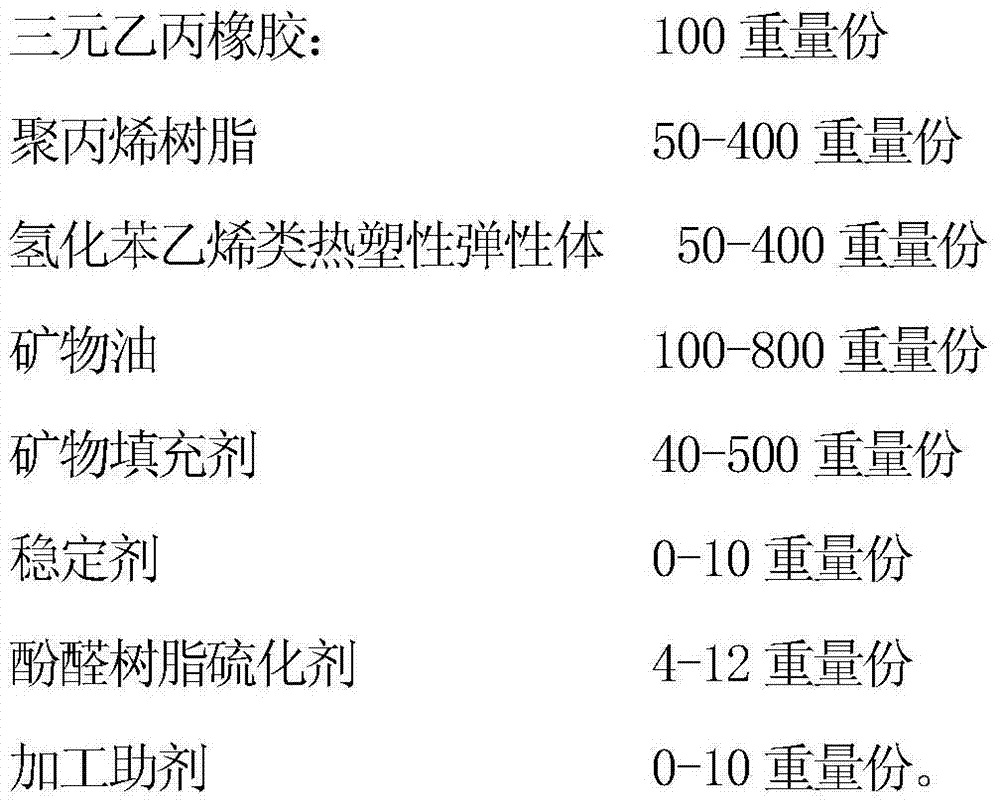

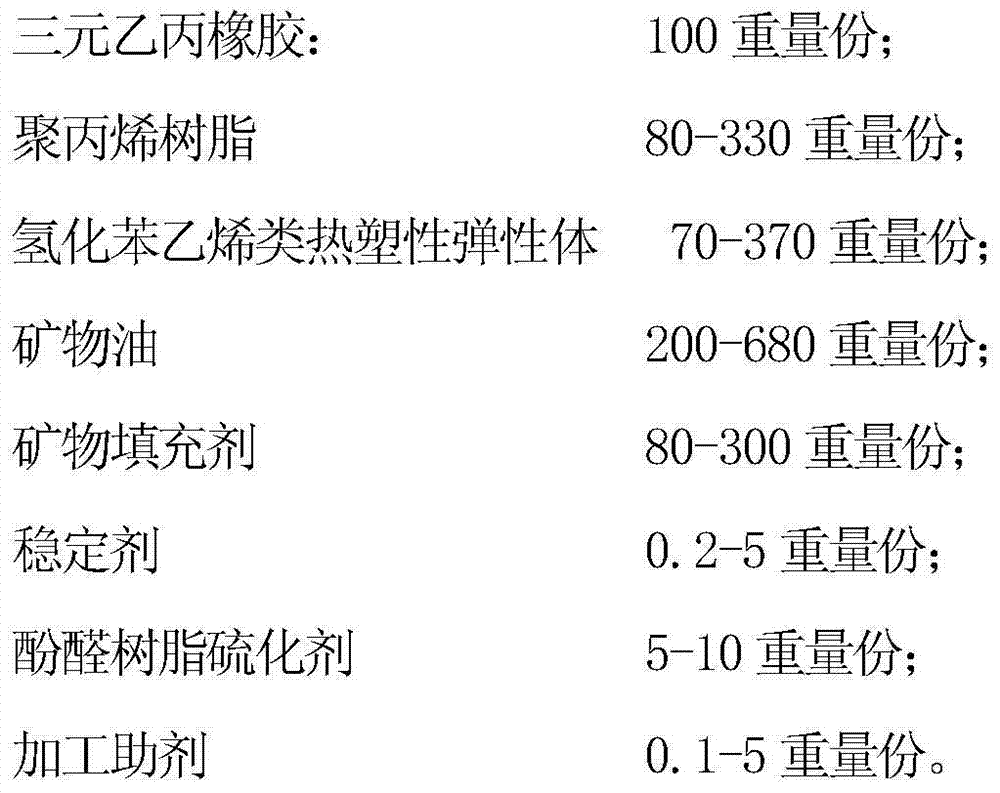

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the thermoplastic vulcanizate elastomer composition improving fluidity of the present invention comprises the following steps:

[0025] (1) Fully mix the styrene-based thermoplastic elastomer and mineral oil;

[0026] (2) After the styrene-based thermoplastic elastomer has fully absorbed the oil, add EPDM rubber, polypropylene resin, mineral fillers, stabilizers such as antioxidants, processing aids, and vulcanizing agents, and mix them in a mixer Uniform;

[0027] (3) Send the homogeneously mixed materials in step (2) into a twin-screw extruder, and undergo twin-screw high-speed shearing, mixing, extrusion, stranding, cooling, and granulation.

[0028] It can be seen from the above technical solutions that the hardness of the thermoplastic elastomer provided by the present invention can be adjusted between 30A and 55D, and the material has good mechanical properties and excellent processability.

[0029] The production process of the thermop...

Embodiment

[0031] The present invention will be further described below in conjunction with embodiment.

[0032] The various raw materials in the embodiments can be purchased from related products of multiple manufacturers. The present invention lists the manufacturers of raw materials, but it should not be construed as a limitation of the present invention.

[0033] Among the following raw materials,

[0034] Dynamic vulcanization elastomer TPV, SANTOPRENE101-55,201-64, purchased from ExxonMobil;

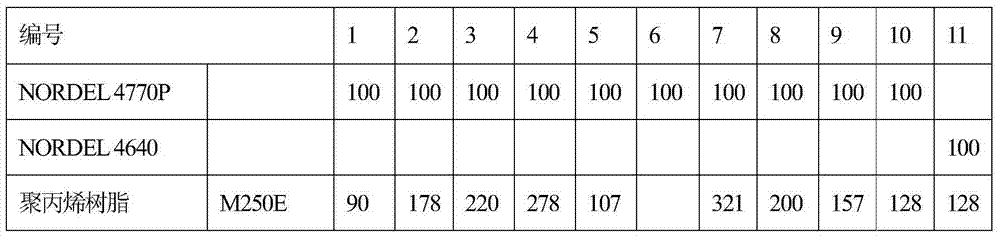

[0035] EPDM rubber: NORDEL4770P, weight average molecular weight 200000, ENB mass content 4.9%; NORDEL4640, weight average molecular weight 160000, ENB mass content 4.9%.

[0036] Polypropylene resin: M250E (random copolymerization), Y2600T (homopolymerization) (purchased from Sinopec, PP), 230°C, melt index at 2.16 kg are 2.5 and 26 respectively;

[0037] Hydrogenated styrene thermoplastic elastomer: 503 (purchased from Yueyang Petrochemical Company, SEBS), 1651, 1654 (purchased from Krato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com