Casting polyurethane elastomer as well as preparation method and application thereof

A polyurethane elastomer and pouring material technology, which is applied in the direction of mechanical equipment, shafts and bearings, engine components, etc., can solve the problems of unsatisfactory mechanical properties and resilience, poor mechanical properties, poor heat resistance, etc., and achieve improved oil resistance , good mechanical properties and heat resistance, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepolymer synthesis: add 350g polyethylene adipate propylene glycol with a molecular weight of 3000 to the reactor, heat to 105°C, dehydrate under vacuum for 2.5h, then lower the material temperature to 70°C, add 105g TODI and 0.05g Bismuth isooctanoate was reacted at 95°C for 1.5h under the protection of nitrogen.

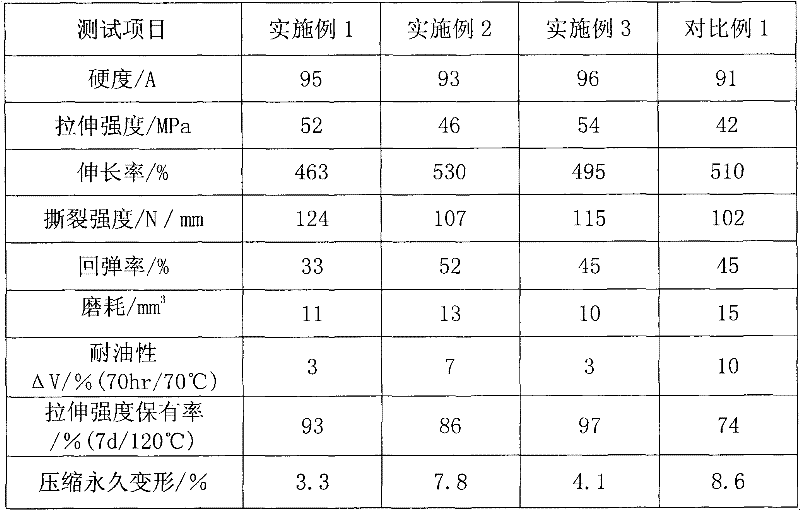

[0025] Preparation of elastomer: Mix the prepolymer and MOCA / TMP (1 / 0.6mol) according to the chain extension coefficient of 0.95, pour into a 4mm mold at 110°C, demould for 20 minutes, vulcanize at 100°C for 20 hours, and measure after 7 days at room temperature performance. The properties of the obtained materials are shown in Table 2.

Embodiment 2

[0027] Prepolymer synthesis: add 300g polytetramethylene polyol with a molecular weight of 650 into the reactor, heat to 105°C, dehydrate under vacuum for 2 hours, then lower the material temperature to 70°C, add 180g TODI and 0.3g tetratitanate n-Butyl ester was reacted at 75°C for 1.5h under the protection of nitrogen.

[0028] Preparation of elastomer: Mix the prepolymer and DMTDA / glycerin (1 / 1mol) according to the chain extension coefficient of 0.85, pour it into a 4mm mold at 100°C, demould it for 20 minutes, vulcanize it at 90°C for 24 hours, and test its performance after standing at room temperature for 7 days . The properties of the obtained materials are shown in Table 2.

Embodiment 3

[0030] Synthesis of prepolymer: add 300g of polycaprolactone with a molecular weight of 1000 to the reactor, heat to 105°C, dehydrate under vacuum for 2 hours, then lower the temperature of the material to 70°C, add 150g of TODI and 0.03g of tetra-n-butyl titanate , reacted at 80°C for 2.5h under nitrogen protection.

[0031] Preparation of elastomer: Mix the prepolymer and MOCA / TMP (1 / 1mol) according to the chain extension coefficient of 0.93, pour into a 4mm mold at 100°C, demould in 30 minutes, vulcanize at 110°C for 16 hours, and test the performance after 7 days at room temperature . The properties of the obtained materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com