Thermoplastic elastomer composition as well as preparation method and application thereof

A thermoplastic elastomer and composition technology, which is applied in the field of thermoplastic elastomer composition and its preparation, can solve the problems of increased hardness and viscosity of SBC, decreased processing performance, inability to exhibit viscoelasticity, etc. good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a preparation method of the thermoplastic elastomer composition, comprising the steps of:

[0074] The styrene block copolymer, white mineral oil and plasticizer are mixed and melted.

[0075] The preparation method has simple technological process and simple equipment requirements, and is suitable for large-scale industrial production.

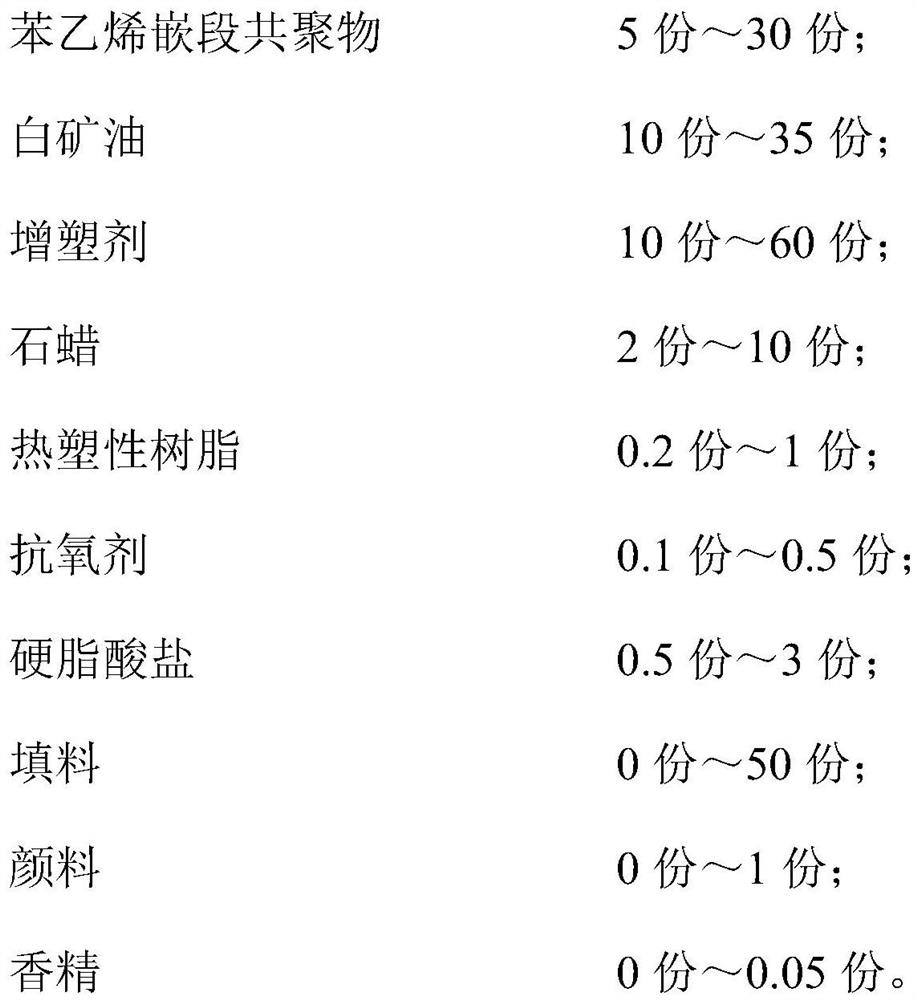

[0076] In one of the embodiments, the thermoplastic elastomer composition contains styrene block copolymer, white mineral oil, plasticizer, paraffin, thermoplastic resin, antioxidant, stearate and other additives ( Filler, pigment, essence), the preparation method of described thermoplastic elastomer composition comprises the steps:

[0077] S110 mixing the plasticizer and white mineral oil, heating and stirring to obtain the first product.

[0078] In one embodiment, the stirring rate is 20r / min-60r / min, the temperature is 120-140°C, and the working time is 10-30min.

[0079] S120 Pour the paraff...

Embodiment 1

[0088] This embodiment provides a thermoplastic elastomer composition and a preparation method thereof.

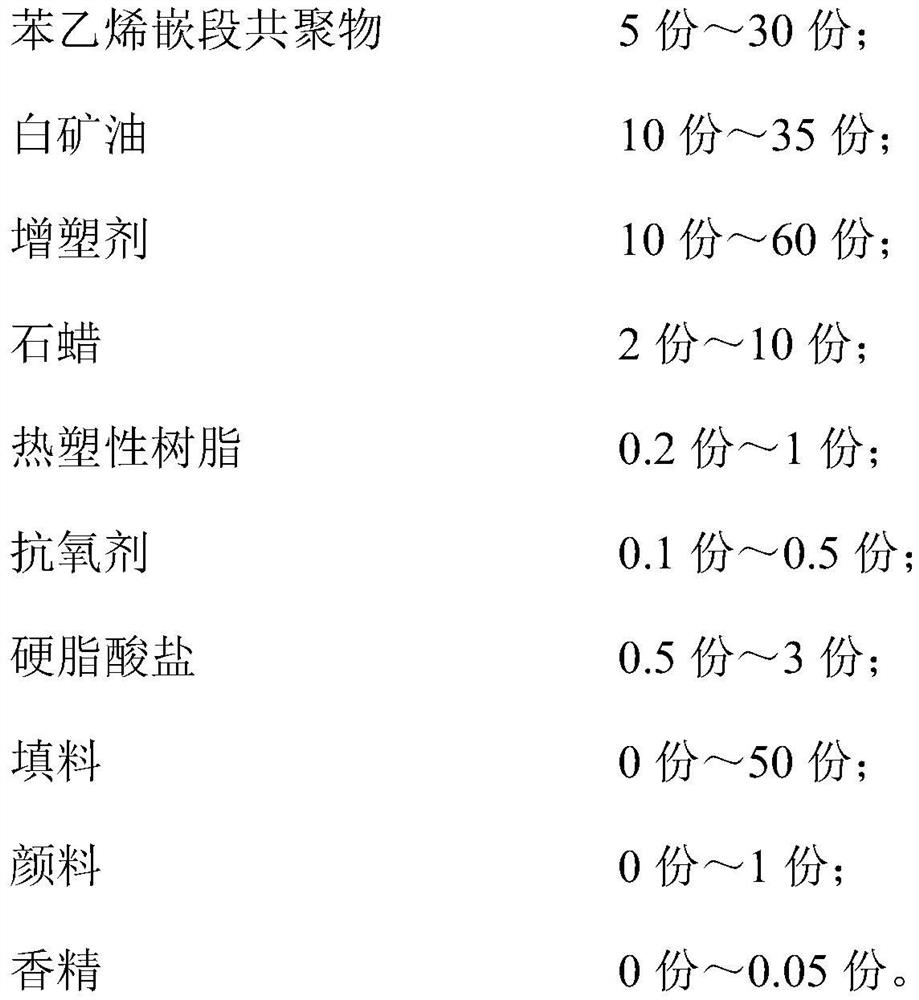

[0089] (1) In parts by weight, the raw materials for the preparation of thermoplastic elastomer composition 1 are as follows:

[0090]

[0091]

[0092] (2) Preparation of thermoplastic elastomer composition 1:

[0093] a: Pour 150N white mineral oil and DINP plasticizer into the reaction kettle, heat, keep the temperature between 120 ~ 140 ℃, stir at a stirring rate of 20r / min ~ 40r / min for 10min ~ 30min, stir until completely uniform After that, the first product is obtained.

[0094] b: Add 64# paraffin wax to the first product at 150-160°C, and stir at a stirring rate of 30r / min-50r / min for 20min-40min until the paraffin wax is completely melted to obtain the second product.

[0095] c: Add SEEPS4055, calcium carbonate, titanium dioxide pigment, strawberry flavor, antioxidant, hydrogenated carbon 5 petroleum resin and stearic acid to the second product under stir...

Embodiment 2

[0098] This embodiment provides a thermoplastic elastomer composition and a preparation method thereof.

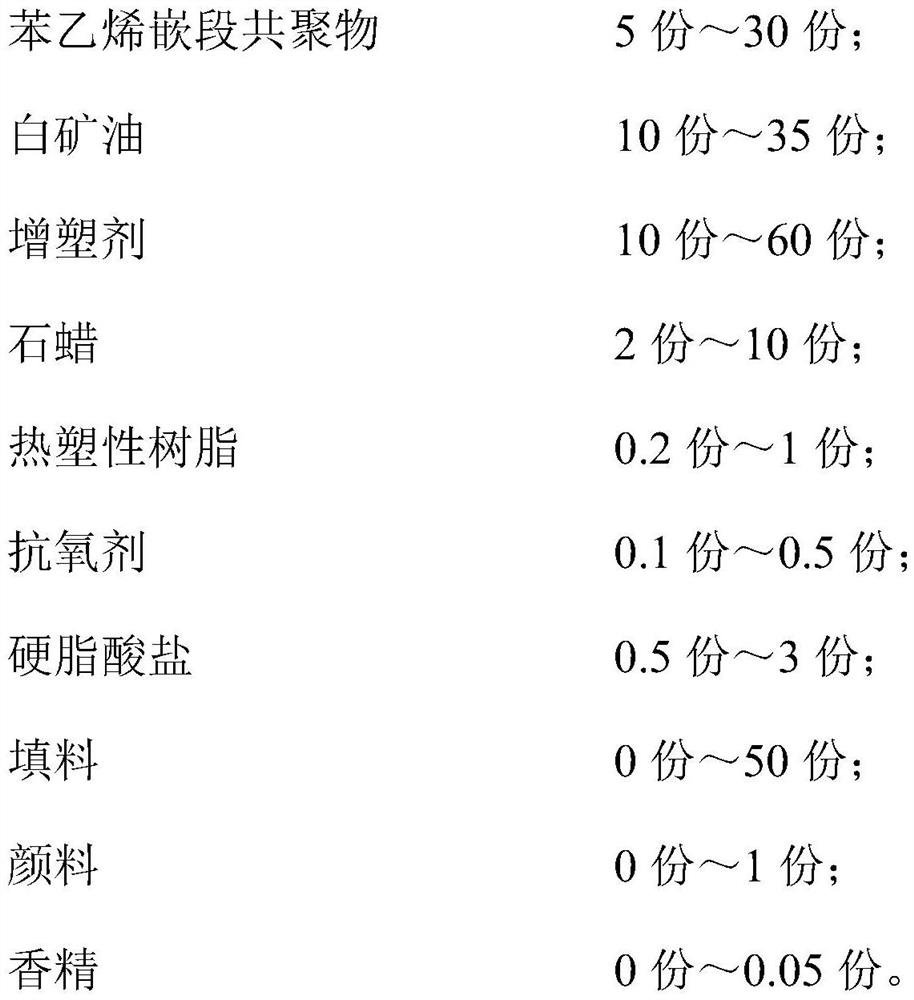

[0099] (1) In parts by weight, the raw materials for the preparation of thermoplastic elastomer composition 2 are as follows:

[0100]

[0101]

[0102] (2) Preparation of thermoplastic elastomer composition 2:

[0103] The preparation method is the same as in Example 1, and a thermoplastic elastomer composition 2 is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com