Plastic and rubber composite material and preparation method thereof

A composite material and rubber technology, applied in the field of rubber and plastic materials, can solve the problems of waste plastics pollution, environmental pollution, etc., achieve good elasticity, obvious enhancement effect, and enhance competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

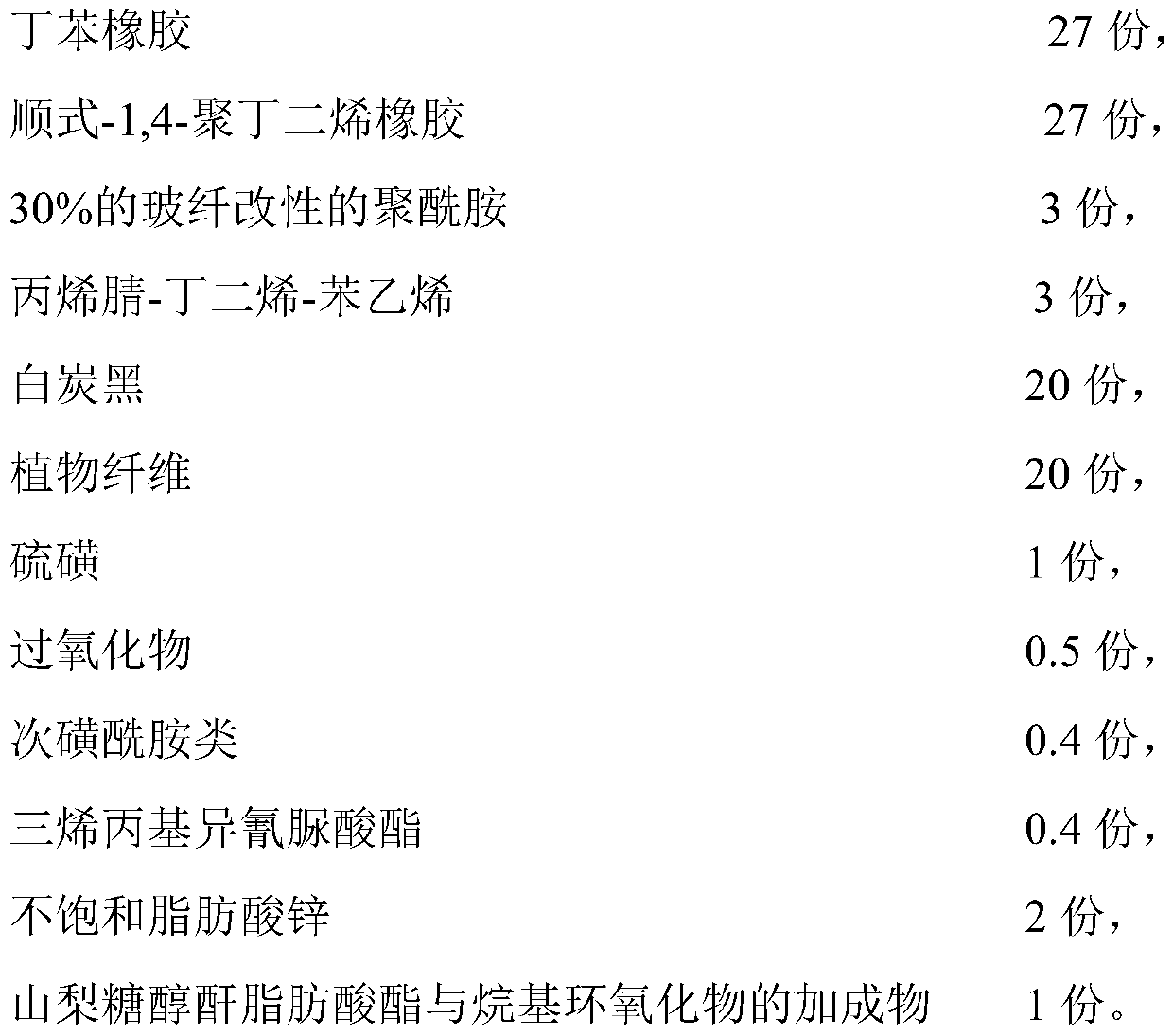

[0025] A composite material of plastic and rubber, comprising the following components in parts by weight:

[0026]

[0027] A preparation method of a composite material of plastics and rubber, comprising the following steps:

[0028] (1) Put styrene-butadiene rubber, cis-1,4-polybutadiene rubber, 30% glass fiber modified polyamide and acrylonitrile-butadiene-styrene into the internal mixer at 100°C Plasticize for 5 minutes, deglue to obtain blended rubber and plastic;

[0029] (2) Then add modified white carbon black, plant fiber, sulfenamides, triallyl isocyanurate, unsaturated fatty acid zinc, sorbitan fatty acid ester and alkyl epoxide in sequence The adduct was mixed at 130°C for 5 minutes, and the next sheet was discharged to obtain a mixed rubber;

[0030] (3) Throwing the mixed rubber, sulfur and peroxide into an open mill for refining, cutting, and cooling in a cooling bucket at -5°C for 24 hours to obtain a mixed billet;

[0031] (4) Put the mixed blank into th...

Embodiment 2

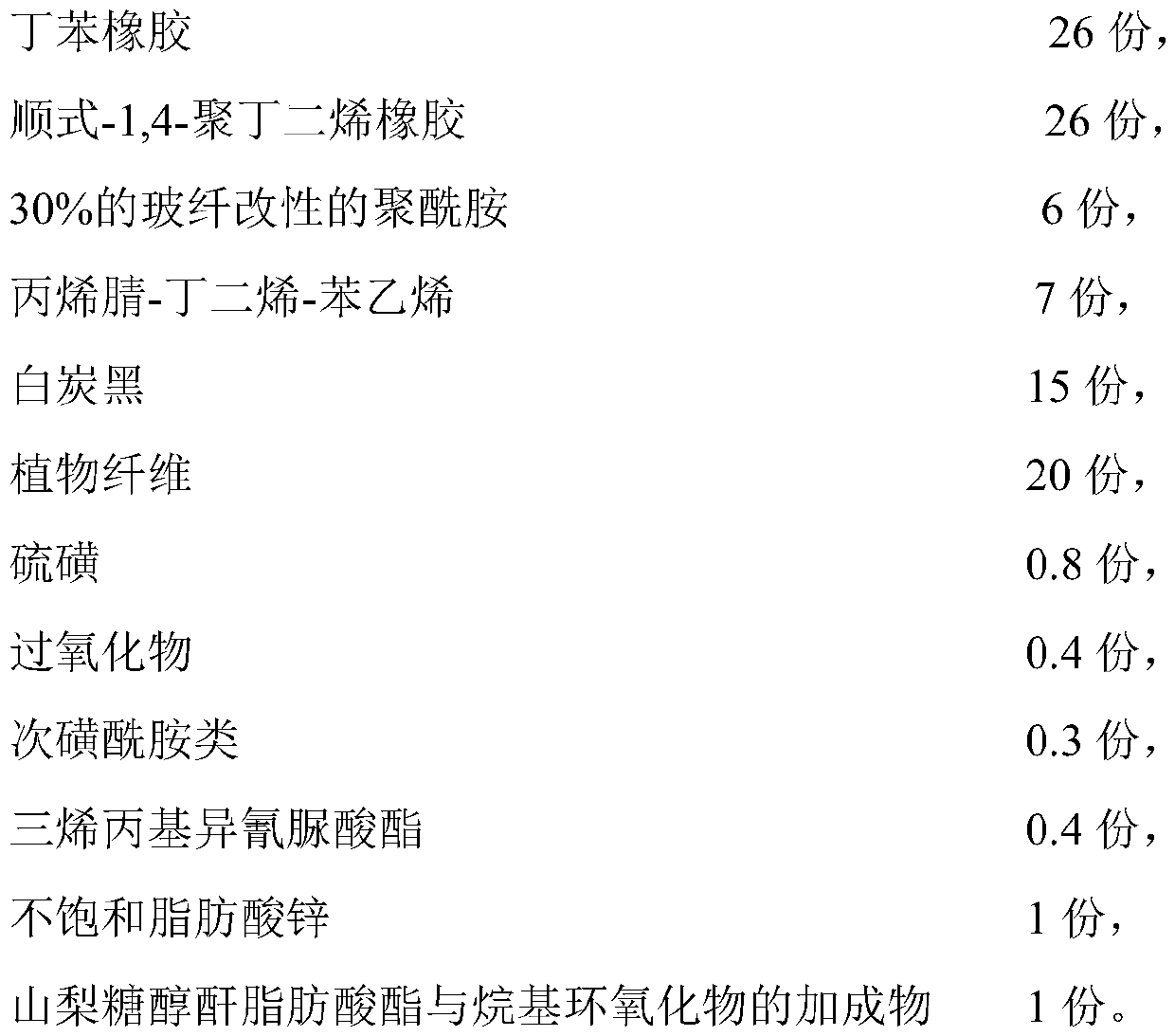

[0034] A composite material of plastic and rubber, comprising the following components in parts by weight:

[0035]

[0036] A preparation method of a composite material of plastics and rubber, comprising the following steps:

[0037] (1) Put styrene-butadiene rubber, cis-1,4-polybutadiene rubber, 30% glass fiber modified polyamide and acrylonitrile-butadiene-styrene into the internal mixer at 100°C Plasticize for 5 minutes, deglue to obtain blended rubber and plastic;

[0038] (2) Then add modified white carbon black, plant fiber, sulfenamides, triallyl isocyanurate, unsaturated fatty acid zinc, sorbitan fatty acid ester and alkyl epoxide in sequence The adduct was mixed at 130°C for 5 minutes, and the next sheet was discharged to obtain a mixed rubber;

[0039] (3) Throwing the mixed rubber, sulfur and peroxide into an open mill for refining, cutting, and cooling in a cooling bucket at -5°C for 24 hours to obtain a mixed billet;

[0040] (4) Put the mixed blank into th...

Embodiment 3

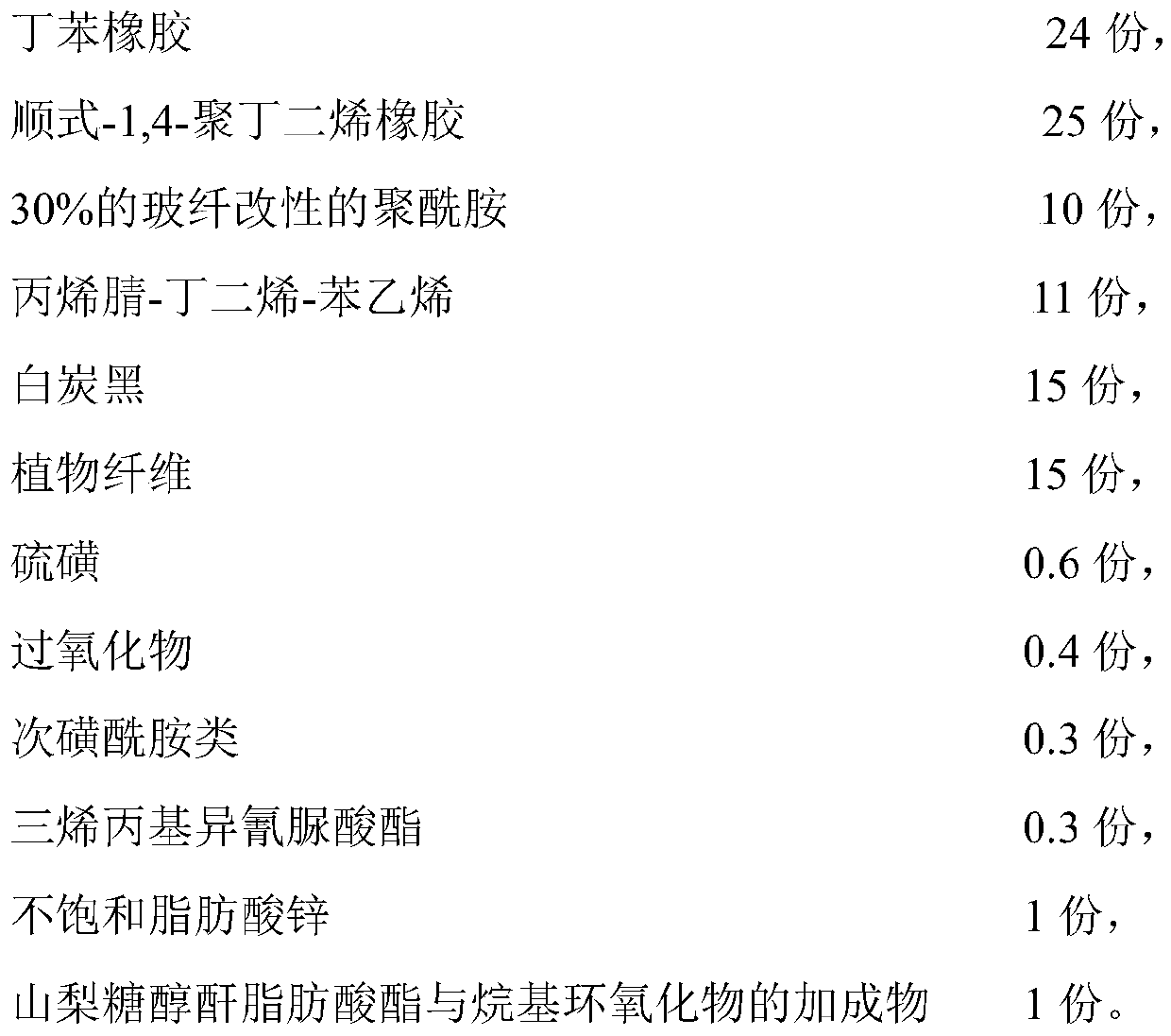

[0043] A composite material of plastic and rubber, comprising the following components in parts by weight:

[0044]

[0045] A preparation method of a composite material of plastics and rubber, comprising the following steps:

[0046] (1) Put styrene-butadiene rubber, cis-1,4-polybutadiene rubber, 30% glass fiber modified polyamide and acrylonitrile-butadiene-styrene into the internal mixer at 100°C Plasticize for 5 minutes, deglue to obtain blended rubber and plastic;

[0047] (2) Then add modified white carbon black, plant fiber, sulfenamides, triallyl isocyanurate, unsaturated fatty acid zinc, sorbitan fatty acid ester and alkyl epoxide in sequence The adduct was mixed at 130°C for 5 minutes, and the next sheet was discharged to obtain a mixed rubber;

[0048] (3) Throwing the mixed rubber, sulfur and peroxide into an open mill for refining, cutting, and cooling in a cooling bucket at -5°C for 24 hours to obtain a mixed billet;

[0049] (4) Put the mixed blank into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com