Novel rubber material of run-flat tire

A technology of anti-explosion tires and rubber materials, which is applied in special tires, tire parts, transportation and packaging, etc., which can solve the problems of reduced vehicle driving performance, easy deformation tire performance, and easy aging of tires, and achieves anti-oxidation, good plasticity, The effect of excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

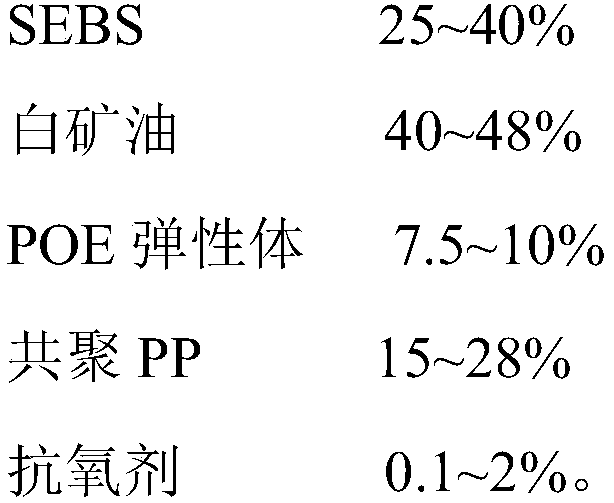

[0029] A kind of rubber material of novel run-flat tire, it is made up of the raw material of following percentage by weight:

[0030]

Embodiment 2

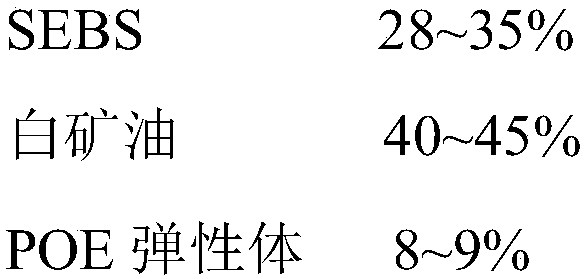

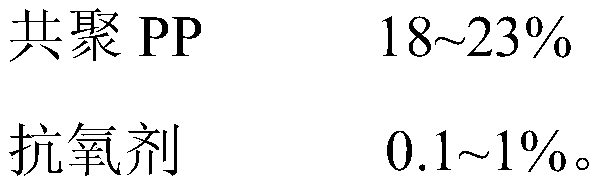

[0032] A kind of rubber material of novel run-flat tire, it is made up of the raw material of following percentage by weight:

[0033]

Embodiment 3

[0035] A kind of rubber material of novel run-flat tire, it is made up of the raw material of following percentage by weight:

[0036]

[0037] In the above examples, SEBS is Kraton G7000, POE elastomer is LG Chemical LC170, copolymerized PP is ethylene copolymerized polypropylene, and antioxidant is 2,2,4-trimethyl-1,2-dihydroquinoline polymer.

[0038] The preparation method of a kind of rubber material of novel explosion-proof tire is, embodiment and comparative example are weighed according to formula, and above-mentioned material is weighed by certain ratio, and SEBS, POE elastomer, copolymerized PP, white mineral oil and antioxidant are weighed. Put them together in a high-speed mixer and mix them. The compounded materials are non-bonding and uniformly dispersed, then put them into a low-speed mixer to cool, and finally mold and cool to make high-temperature-resistant automobile tires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com