Ecological floating bed for oil-polluted water remediation

A technology of water body restoration and ecological floating bed, which is applied in the fields of water pollutants, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the loss of catalytic materials, poor recyclability and reusability of catalysts, and limited photocatalysis Wide application of materials and other issues to achieve strong adsorption performance, good visible light activity, enhanced adsorption and degradation performance and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

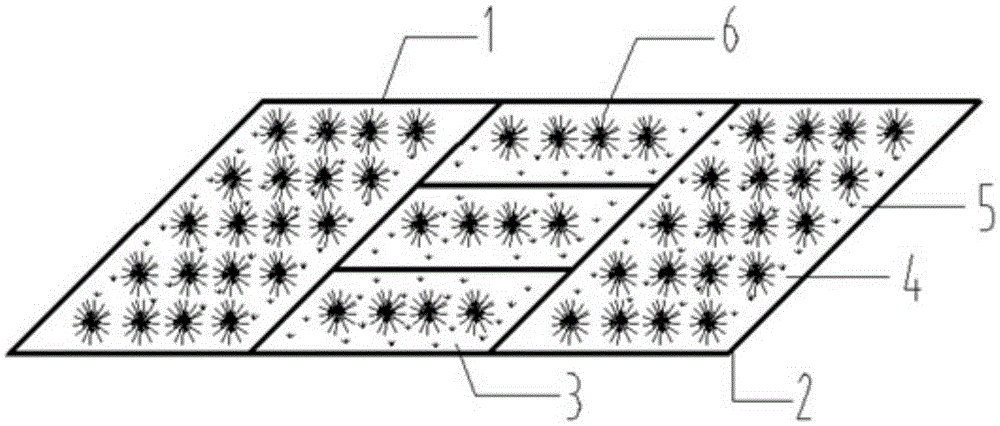

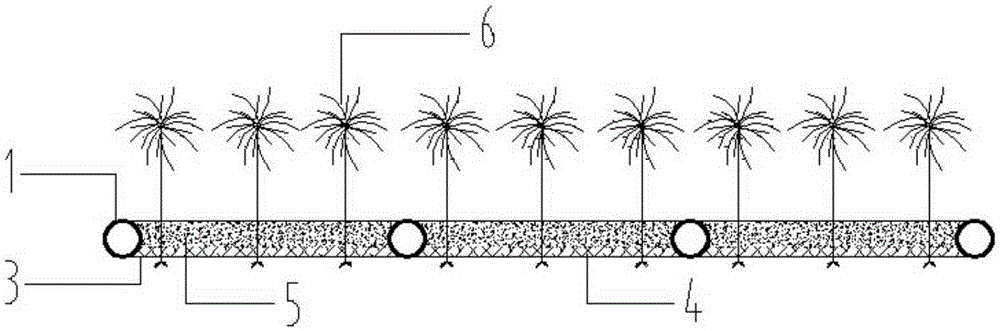

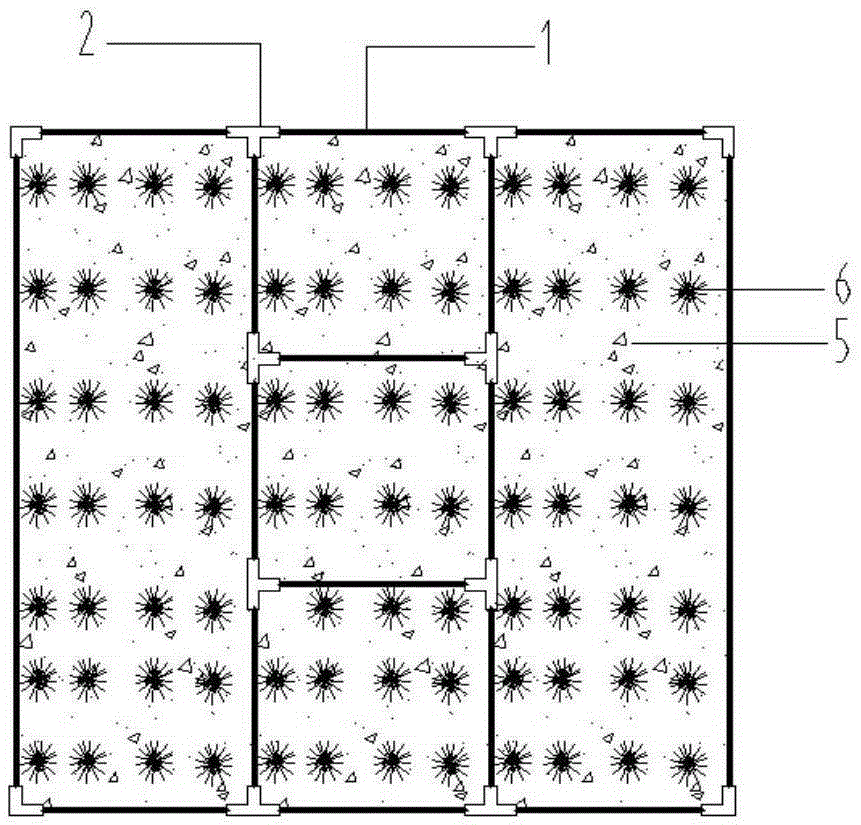

[0039] An ecological floating bed for remediation of oil-polluted water prepared based on waste materials, comprising: a main frame 1, a PVC casing joint 2, a non-woven fabric 3, a bottom filling material 4, an upper filling material 5, and the Agricultural plants6.

[0040] The main frame is made of 6 casing supports with a length of 0.9m, 2 casing supports with a length of 0.3m, 4 DN15 right-angle two-way joints, and 8 DN15 positive tee joints. The casing supports are made of waste polyurethane foam Plastic loaded with TiO infiltrated with a certain amount of N element 2 The material is prefabricated. refer to Figure 1 to Figure 3 Assembled, the interface is sealed with a small amount of silicone.

[0041] The production process of the main frame is as follows: take 300g of waste polyurethane foam, use a small molecule alkyl glycol as an alcoholysis agent, and react for 2 hours at 200°C to obtain a polyether polyol; 20mL of tetrabutyl titanate Add the ester to 10mL of a...

Embodiment example 2

[0046] The production process of this case refers to the implementation case 1, but there are the following differences: the main frame is assembled from six 0.3m and two 0.1m casing brackets, and the production process of the casing brackets has the following differences: Take 100g of waste polyurethane foam plastics to obtain polyether polyols; add 6 mL of tetrabutyl titanate to 3 mL of absolute ethanol under vigorous stirring, stir for 30 min, then add dropwise 1.5 mL of concentrated nitric acid, 2 mL of twice distilled water and 25 mL of absolute ethanol Mix the solution to make TiO 2 dry gel. urea and TiO 2 Xerogels were mixed and ground at different mass ratios of 3:1 to prepare N-doped TiO 2 Nanoparticles. 8 g of N-doped TiO 2 Particles, mixed with 80g of diphenylmethylpropane diisocyanate, heated in a water bath at 40°C to form a liquid; mixed 15g of dichloromethane with 80g of polyether polyol, heated in a 60°C water bath and continuously stirred to form a liquid;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com