Method for plug removal of triassic oil reservoir in nitrogen foam acidification mode

A nitrogen foam, triassic technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of short validity period and poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for removing plugging by nitrogen foam acidification of a Triassic reservoir according to the present invention:

[0025] (1) 12% hydrochloric acid, 3% hydrofluoric acid, 0.8% sodium dodecyl sulfate, 0.3% polyacrylamide (molecular weight 13 million), 0.5% thiourea, 1% imidazoline, and the rest are water; on site Prepare the pre-fluid in the liquid distribution tank.

[0026] (2) Mix 8% hydrochloric acid, 1% hydrofluoric acid, 0.8% EL-23 type E foaming agent, 0.3% foam stabilizer D, 0.5% iron ion stabilizer EL-12, 1% corrosion inhibitor EL- 10 Prepare the working fluid in the liquid mixing tank, and the rest is water; the EL-23 foaming agent is a compound of cetyltrimethylammonium bromide and alkylphenol polyoxyethylene ether.

[0027] (3) 0.5% OP-10 and 1% clay stabilizer are prepared in the liquid mixing tank to make the post liquid, and the rest is water.

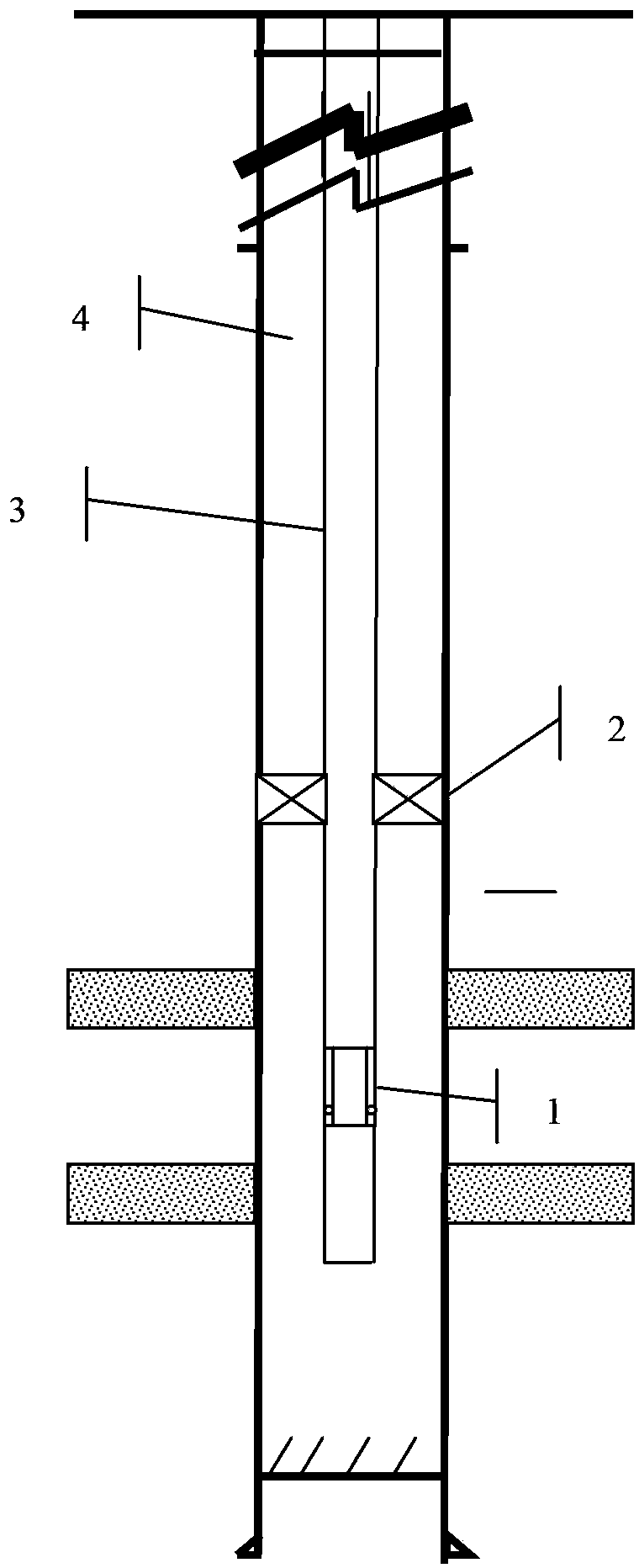

[0028] (4) The structure of the acidizing drilling tool from bottom to top consists of a sliding slee...

Embodiment 2

[0038] A method for removing plugging by nitrogen foam acidification of a Triassic reservoir according to the present invention:

[0039] (1) 10% hydrochloric acid, 1% hydrofluoric acid, 0.5% sodium dodecyl sulfate, 0.1% polyacrylamide (molecular weight 13 million), 0.3% thiourea, 0.5% imidazoline, and the rest are water; on site Prepare the pre-fluid in the liquid distribution tank.

[0040] (2) Mix 5% hydrochloric acid, 1% hydrofluoric acid, 0.5% EL-23 type E foaming agent, 0.1% foam stabilizer D, 0.3% iron ion stabilizer EL-12, 0.5% corrosion inhibitor EL- 10 Prepare the working fluid in the liquid distribution tank, and the rest is water. EL-23 foaming agent is a compound of cetyltrimethylammonium bromide and alkylphenol polyoxyethylene ether.

[0041] (3) 0.5% OP-10 and 1% clay stabilizer are prepared in the liquid mixing tank to make the post liquid, and the rest is water.

[0042] (4) The structure of the acidizing drilling tool from bottom to top consists of a slidi...

Embodiment 3

[0052] A method for removing plugging by nitrogen foam acidification of a Triassic reservoir according to the present invention:

[0053] (1) 11% hydrochloric acid, 2% hydrofluoric acid, 0.7% sodium dodecyl sulfate, 0.2% polyacrylamide (molecular weight 13 million), 0.4% thiourea, 0.8% imidazoline, and the rest are water; on site Prepare the pre-fluid in the liquid distribution tank.

[0054] (2) Mix 7% hydrochloric acid, 1% hydrofluoric acid, 0.7% EL-23 type E foaming agent, 0.2% foam stabilizer D, 0.4% iron ion stabilizer EL-12, 0.8% corrosion inhibitor EL- 10 Prepare the working fluid in the liquid distribution tank, and the rest is water. EL-23 foaming agent is a compound of cetyltrimethylammonium bromide and alkylphenol polyoxyethylene ether.

[0055] (3) 0.5% OP-10 and 1% clay stabilizer are prepared in the liquid mixing tank to make the post liquid, and the rest is water.

[0056] (4) The structure of the acidizing drilling tool from bottom to top consists of a sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com