Temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent and preparation method thereof

A technology for cleaning fracturing fluids and polymers, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem that the production and application of clean fracturing fluid thickeners have not achieved due effects, and new products are difficult to enter On-site and other problems, to achieve excellent shear thinning, easy flowback, good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

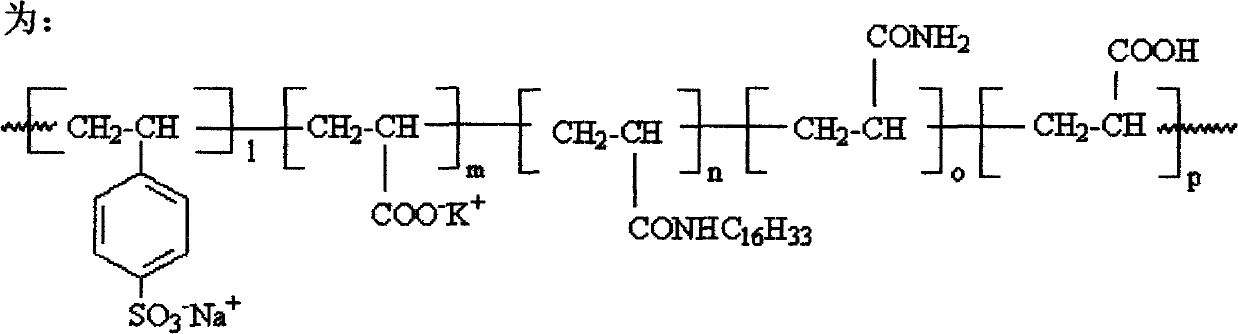

[0055] Preparation and performance test of temperature-resistant and salt-resistant polymer clean fracturing fluid thickener 1:

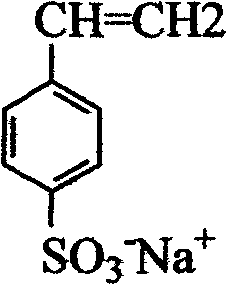

[0056] 1. Weigh 76g of hexadecylamine and dissolve it in 103.2g of toluene solvent, add 20g of acrylic acid and 0.8g of sodium p-toluenesulfonate, and pass through a water separator to seal the reaction at 86°C and separate the water produced by the reaction , reacted for 24h, and then distilled under reduced pressure at 90°C for 9h until there was no distillate. After cooling to room temperature, the light yellow oily solid obtained in the reactor was the associated monomer N-hexadecyl acrylamide.

[0057] 2. Weigh 3g of potassium hydroxide and dissolve it in 22g of deionized water to prepare a potassium hydroxide solution. Then take by weighing 4.8g of acrylic acid, after the two carry out neutralization reaction for 30min, take by weighing 3g of the association monomer N-hexadecyl acrylamide synthesized in the first step, and 2.4g of the anionic ...

Embodiment 2

[0061] Preparation and performance test of temperature-resistant and salt-resistant polymer clean fracturing fluid thickener 2:

[0062] 1. Weigh 126g of hexadecylamine and dissolve it in 137.4g of toluene solvent, add 36g of acrylic acid and 0.6g of sodium p-toluenesulfonate, and pass through a water separator to seal the reaction at 93°C and separate the water produced by the reaction , reacted for 20h, and then distilled under reduced pressure at 81°C for 11h until there was no distillate. After cooling to room temperature, the light yellow oily solid obtained in the reaction kettle was the association monomer N-hexadecyl acrylamide.

[0063] 2. Weigh 9.8g of potassium hydroxide and dissolve it in 79.3g of deionized water to prepare potassium hydroxide solution. Then take 14g of acrylic acid, and weigh 6.3g of the associative monomer N-hexadecylacrylamide synthesized in the first step, and 4.2g of the anionic monomer p-vinylbenzenesulfonate after the neutralization reaction...

Embodiment 3

[0067] Preparation and performance test of temperature-resistant and salt-resistant polymer clean fracturing fluid thickener 3:

[0068] 1. Weigh 160g of hexadecylamine and dissolve it in 194.8g of toluene solvent, add 44g of acrylic acid, 1.2g of sodium p-toluenesulfonate, and pass through a water separator to seal the reaction at 90°C and separate the water produced by the reaction , reacted for 22h, and then distilled under reduced pressure at 86°C for 10h until there was no distillate. After cooling to room temperature, the light yellow oily solid obtained in the reaction kettle was the association monomer N-hexadecyl acrylamide.

[0069] 2. Weigh 7.2g of potassium hydroxide and dissolve it in 64.8g of deionized water to prepare a potassium hydroxide solution. Then take by weighing 10.8g of acrylic acid, and weigh 4.8g of the associative monomer N-hexadecylacrylamide synthesized in the first step after the neutralization reaction of the two, and 6g of the anionic monomer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com