Low-solid phase ultrahigh-temperature water-based drilling fluid and preparation method thereof

A water-based drilling fluid, ultra-high temperature technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unstable drilling fluid performance, high solid content, poor rock-carrying ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

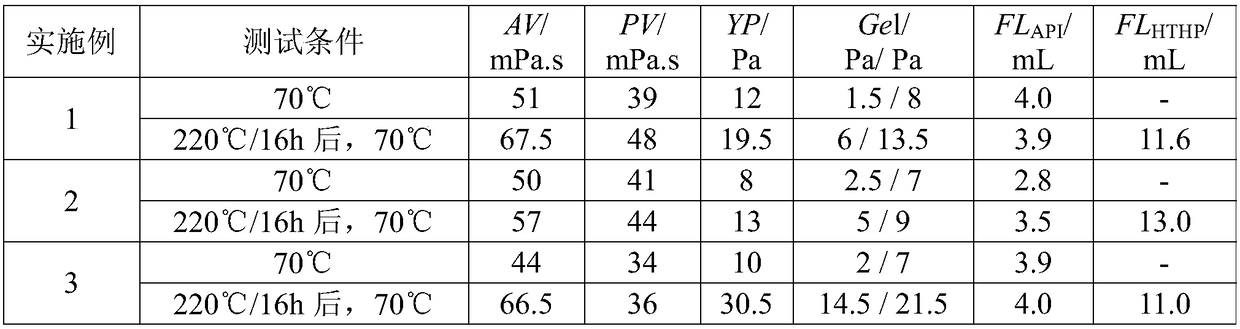

Embodiment 1

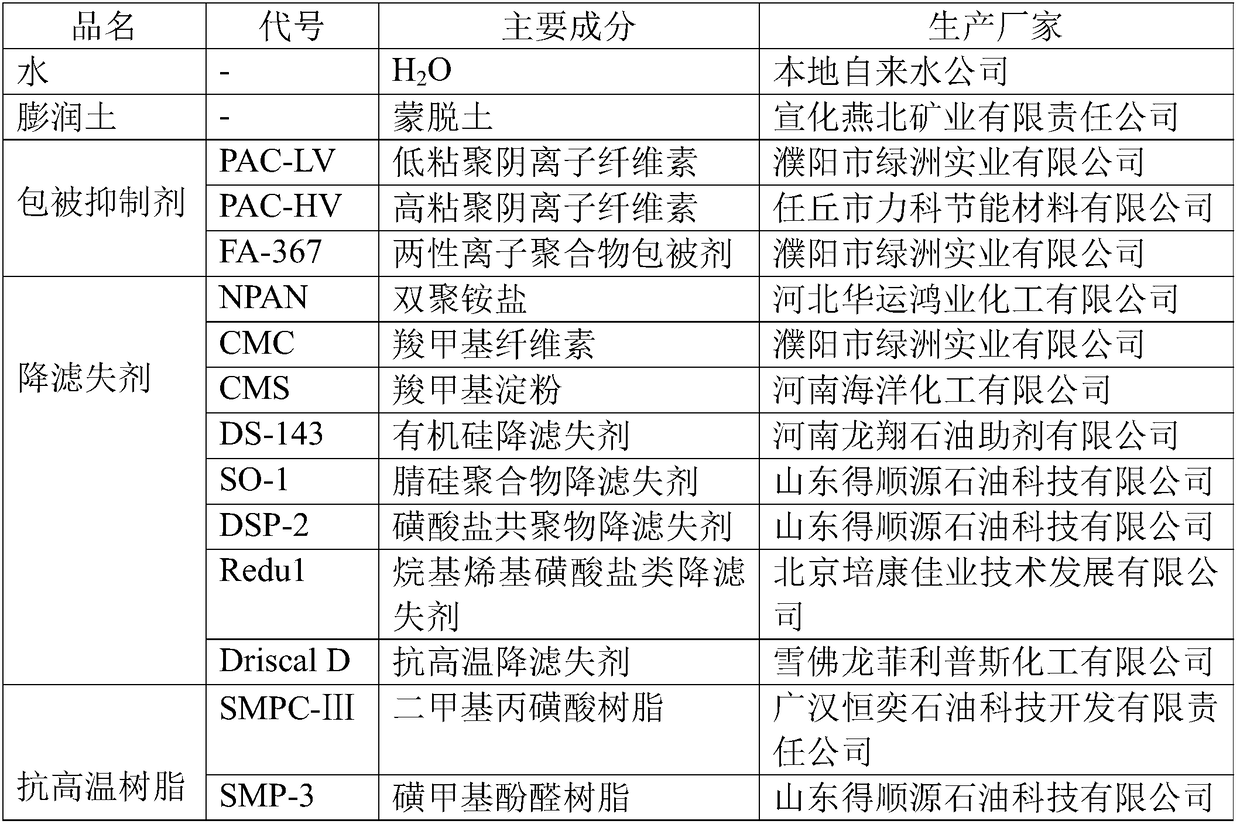

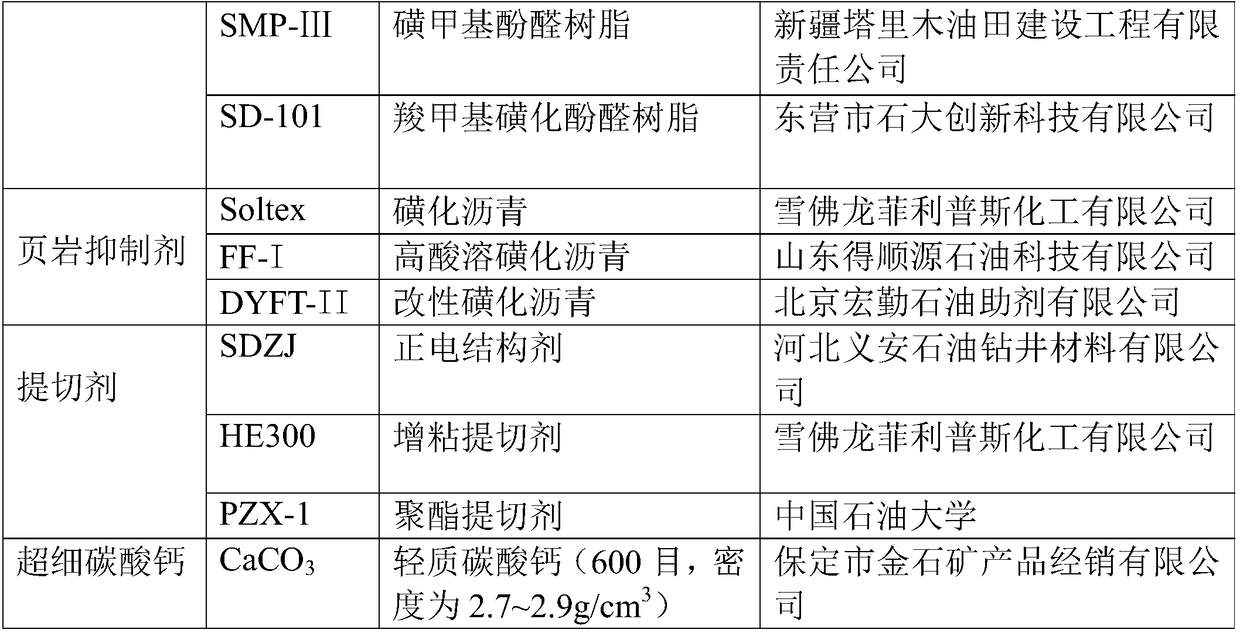

[0035] Low-solid ultra-high temperature water-based drilling fluid products I:

[0036] First measure 400mL of solvent water, add 3g bentonite and 0.15g anhydrous sodium carbonate while stirring, stir at low speed for 20min, and cure for 24h at room temperature to make pre-hydrated bentonite slurry; then put the pre-hydrated bentonite slurry on the high mixer , Under high-speed 11000r / min electric stirring, add 4g PAC-LV, 4g PAC-HV and 0.8g FA-367 in sequence, stir for 20min, then add 2g CMS, 6g DS-143, 2g Redu-1, 4g Driscal D, Continue stirring for 20 minutes and then add 10g SMPC-Ⅲ, 10g DYFT-II, 8gHE-300 and 60g ultrafine calcium carbonate. After the addition is complete, stir for 20min, and then hydrate at room temperature for 24h to obtain the low solid phase ultra-high temperature water base Drilling fluid, its density is 1.10g / cm 3 .

Embodiment 2

[0038] Low-solid ultra-high temperature water-based drilling fluid products I:

[0039] First measure 400mL of solvent water, add 4g bentonite and 0.2g anhydrous sodium carbonate while stirring, stir at low speed for 20 minutes, and cure at room temperature for 24 hours to make pre-hydrated bentonite slurry; then put the pre-hydrated bentonite slurry on a high mixer , Under high-speed 11000r / min electric stirring, add 4g PAC-LV, 2g PAC-HV and 1.2g FA-367 in turn, stir for 20min, then add 2g NPAN, 4g DS-143, 2g DSP-2, 3.2g Driscal D After stirring for 20 minutes, add 8g SMP-3, 8gFF-I, 6g SDZJ and 102g ultrafine calcium carbonate, stir for 20min after the addition, and then hydrate for 24h at room temperature to obtain the low solid phase ultra-high temperature water-based drilling Liquid, its density is 1.15g / cm 3 .

Embodiment 3

[0041] Low-solid ultra-high temperature water-based drilling fluid product III:

[0042] First measure 400mL of solvent water, add 4g bentonite and 0.2g anhydrous sodium carbonate while stirring, stir at low speed for 20 minutes, and cure at room temperature for 24 hours to make pre-hydrated bentonite slurry; then put the pre-hydrated bentonite slurry on a high mixer , Under high-speed 11000r / min electric stirring, add 4g PAC-LV, 2.8g PAC-HV, 0.8g FA-367 in sequence, stir for 20min, then add 2g NPAN, 6g SO-1, 2g Redu-1, 8g Driscal D After stirring for 20 minutes, add 8g SMP-Ⅲ, 8gSoltex, 6gPZX-1 and 140g ultrafine calcium carbonate. After the addition, stir for 20min and rehydrate for 24h to obtain the low solid phase ultra-high temperature water-based drilling fluid , Its density is 1.2g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com