Patents

Literature

53results about How to "Good on-site use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crude oil pour point depressant and preparation method thereof

ActiveCN101845299ADosage is smallLarge range of pour point reductionDrilling compositionMaleic anhydrideWax

The invention discloses a crude oil pour point depressant, which is compounded by the following components in percentage by weight: 99.0 to 99.8 percent of quadripolymer, 0.1 to 0.5 percent of fumed silica, and 0.1 to 0.5 percent of nonionic fluorocarbon surfactant, wherein the quadripolymer is formed by polymerizing monomer higher alcohol acrylate, methylacrylic acid, maleic anhydride, and styrene. The crude oil pour point depressant has the advantages of small dosage, great pour point depression, excellent wax resistance effect, and the like. The experimental results prove that: the pour point depressant obviously lowers the condensation point of the crude oil, widens the Newton fluid temperature range of the crude oil, and reduces the viscosity at non-Newton fluid temperature. In the application of Jianghan oilfield, the freezing point of the crude oil can be reduced to 7 DEG C below zero from 25 DEG C by adding 0.025 mass percent of the pour point depressant, the reduction range is 32 DEG C, and the on-site using effect is good.

Owner:HUBEI UNIV +1

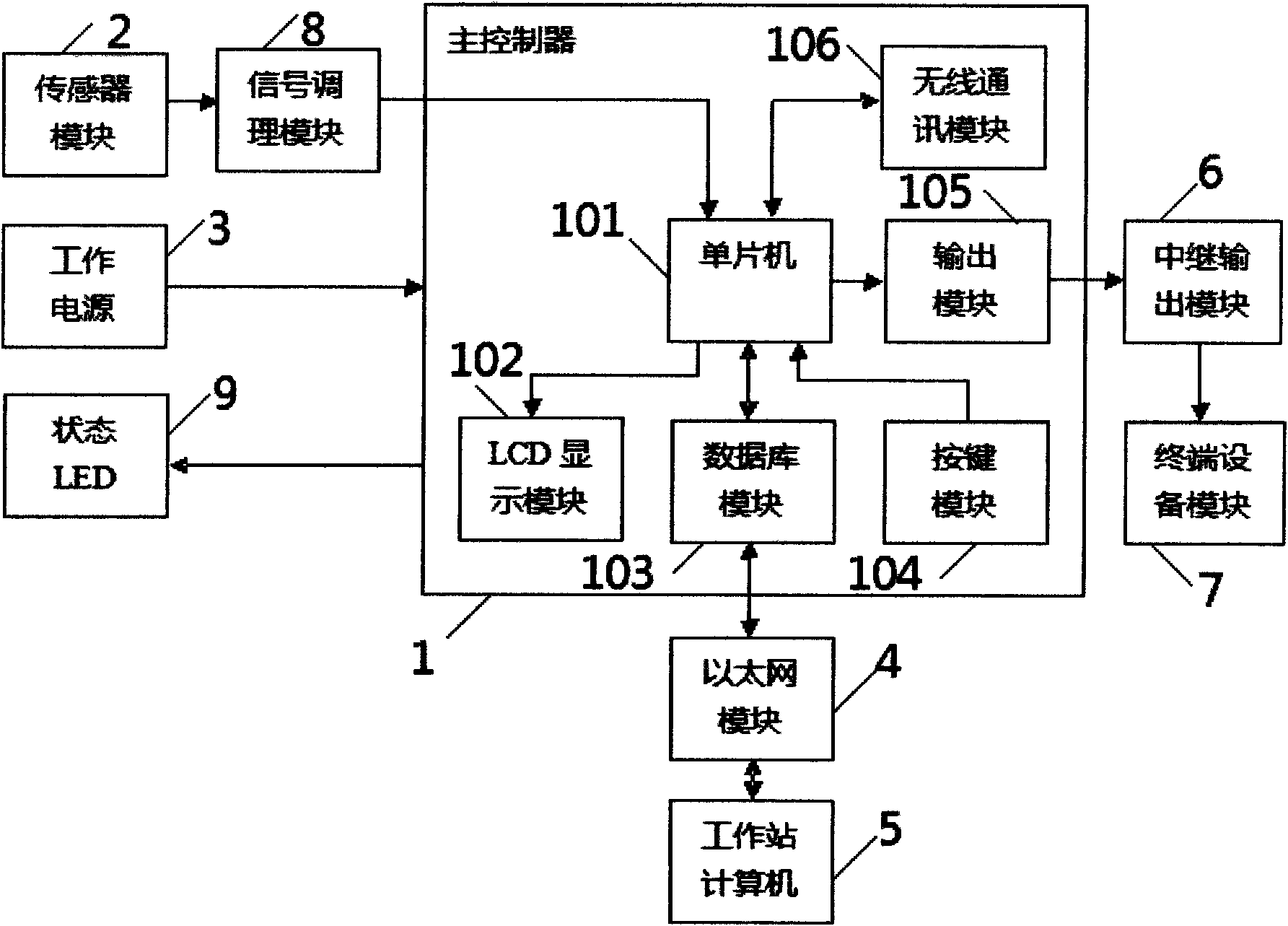

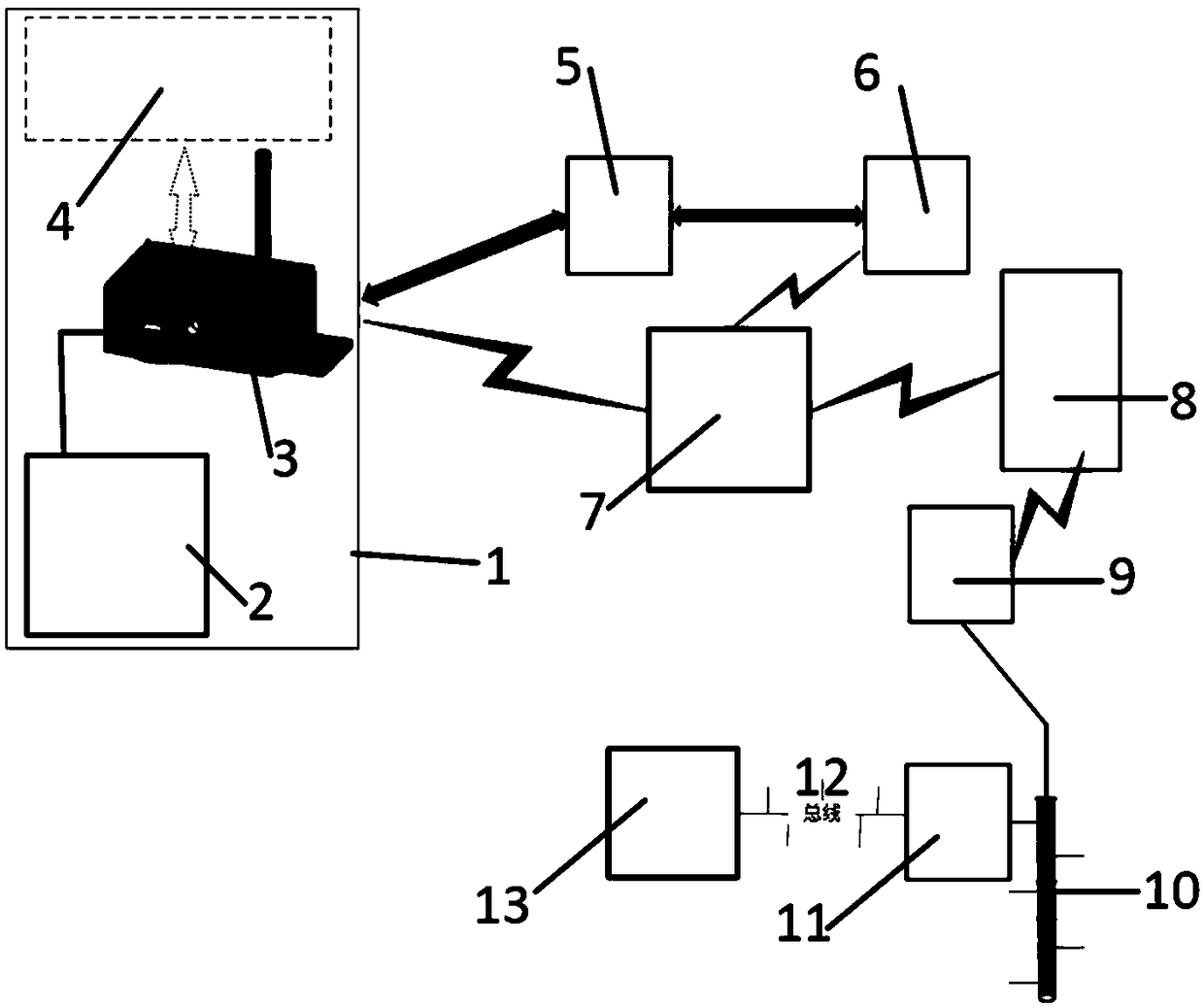

Multipath water quality online monitoring system

InactiveCN102736569AAvoid water quality deteriorationEasy to maintainPisciculture and aquariaTotal factory controlWater qualityAquatic product

The invention discloses a multipath water quality online monitoring system which comprises a main controller. The main controller comprises a single chip computer, an LCD display module, a database module, a keyboard module and an output module. The single chip computer is connected with the LCD display module, the database module, the keyboard module and the output module. The single chip computer also is connected with a sensor module through a signal conditioning module. The database module is connected with a workstation computer through an Ethernet module. The output module is connected with a terminal equipment module through a relay output module. The main control unit is connected with a working power supply. According to the invention, the real-time monitoring of water quality can be realized, and the multipath water quality online monitoring system satisfies requirements of aquatic product scientific research, a large-scale aquaculture plant using recycled water culture, and industrialization.

Owner:苏州滨特尔水处理有限公司

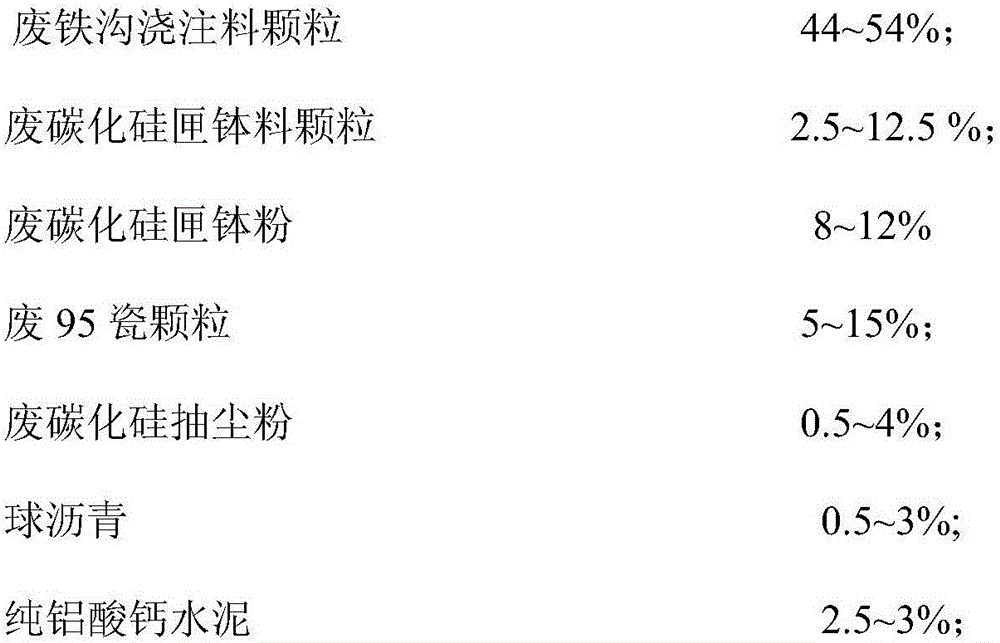

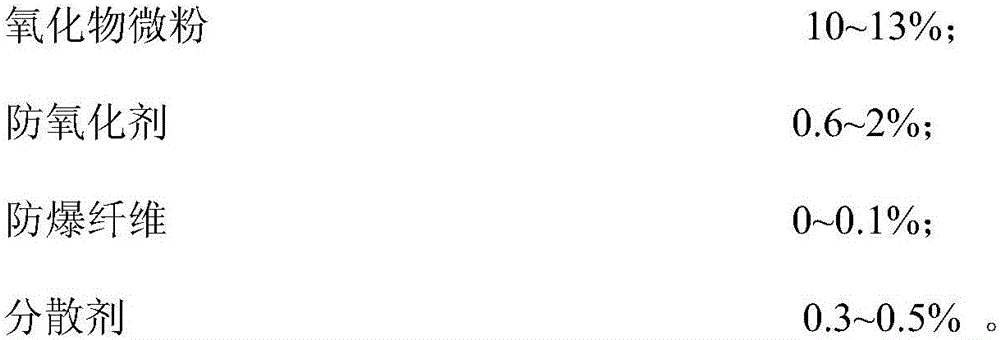

Iron runner castable containing 80% of waste refractories or above

The invention belongs to the field of undetermined refractory materials and particularly relates to iron runner castable containing 80% of waste refractories or above. The iron runner castable is prepared from, by mass, 44%-54% of waste iron runner castable particles, 2.5%-12.5% of waste silicon carbide sagger material particles, 8%-12% of waste silicon carbide sagger powder, 5%-15% of waste 95 ceramic particles, 0.5%-4% of waste silicon carbide dust drawing powder, 0.5%-3% of pitch balls, 2.5%-3% of pure calcium aluminate cement, 10%-13% of oxide micro powder, 0.6%-2% of antioxidant, 0%-0.1% of anti-explosion fibers and 0.3%-0.5% of dispersing agent. The utilization proportion of the waste refractories of the iron runner castable reaches 80% or above, industrial application proves that the field use effect of the iron runner castable is good, volume production operability is high, the raw material cost is low, and advantages of economic benefits and social benefits are achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

Composite metal ceramic powder, furnace roller coated with same and preparation method thereof

ActiveCN101838767AImprove compactnessImprove structural uniformityMolten spray coatingChromium carbideSurface layer

The invention discloses a composite metal ceramic powder, a furnace roller coated with the same and a preparation method thereof. The composite metal ceramic powder contains the following components in percentage by weight: 35-70 percent of MCrAlY or MCrAlTaY, 25-45 percent of Cr3C2 and 5-20 percent of Na2Ti6O13 or K2Ti6O13, wherein M is Ni, Co or Ni-Co alloy. The furnace roller comprises a workpiece substrate and a coating sprayed on the workpiece substrate, wherein the coating comprises a surface layer and a bottom layer or a single surface layer, and the surface layer is made of the composite metal ceramic powder. The furnace roller is prepared by adopting a high-speed oxygen flame spraying method and has excellent heat resistance, wear resistance and nodule resistance performances and average service period reaching over 2 years.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic sprayer of blasting

InactiveCN101586468ASave time for sprinkling dustImprove spraying effectDust removalFire preventionSprayerWater resources

The present invention discloses an automatic sprayer of blasting, which is composed of a spray gun body and a nozzle. The tail of the spray gun body is provided with a high-pressure wind inlet pipe and a high-pressure water inlet pipe. The nozzle is a wedge-shaped nozzle. The upper surface, the lower surface, the front surface and the back surface of the wedge-shaped nozzle are provided with spraying holes. A high-pressure blower which supplies wind to the high-pressure wind inlet pipe is provided with a blasting vibration automatic opening device. The nozzle is installed in the middle part of the laneway top which is separated from the working surface for 25-30 meters. The automatic sprayer of blasting of the invention has the advantages of: safe and convenient using, good construction environment, capability for removing dust instantly, and water resource saving.

Owner:中煤第一建设有限公司第四十九工程处

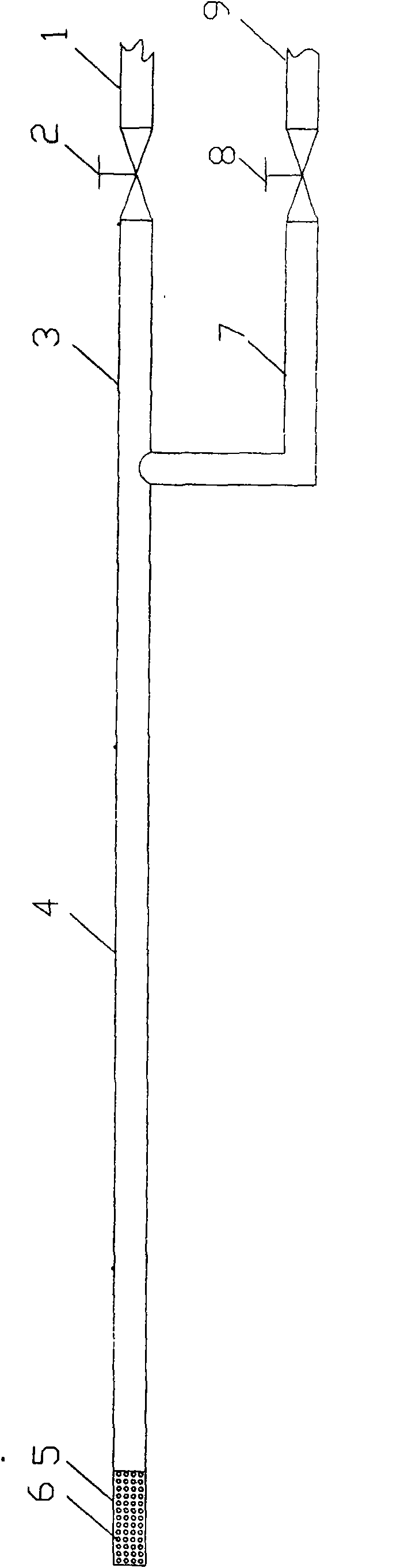

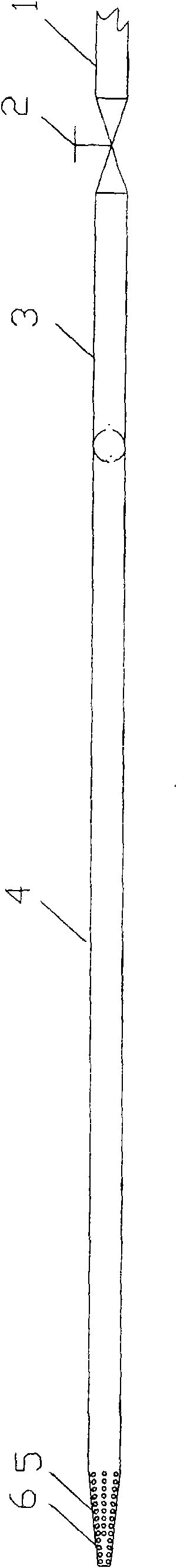

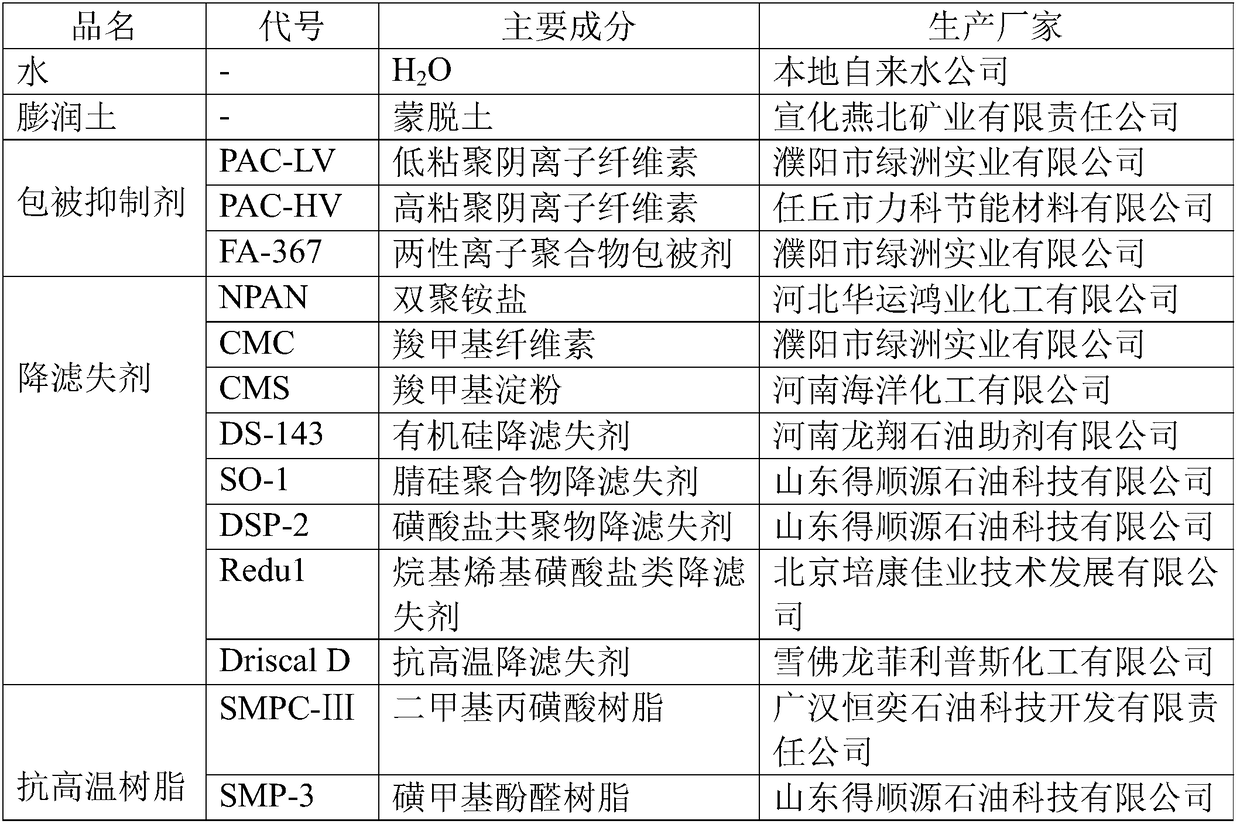

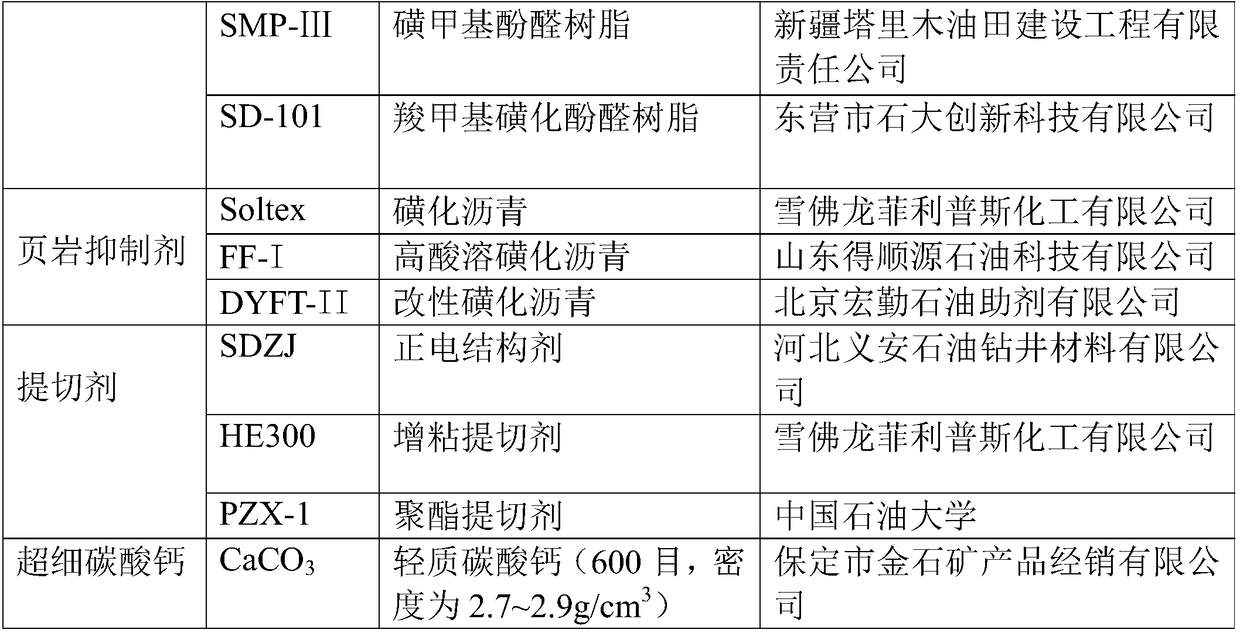

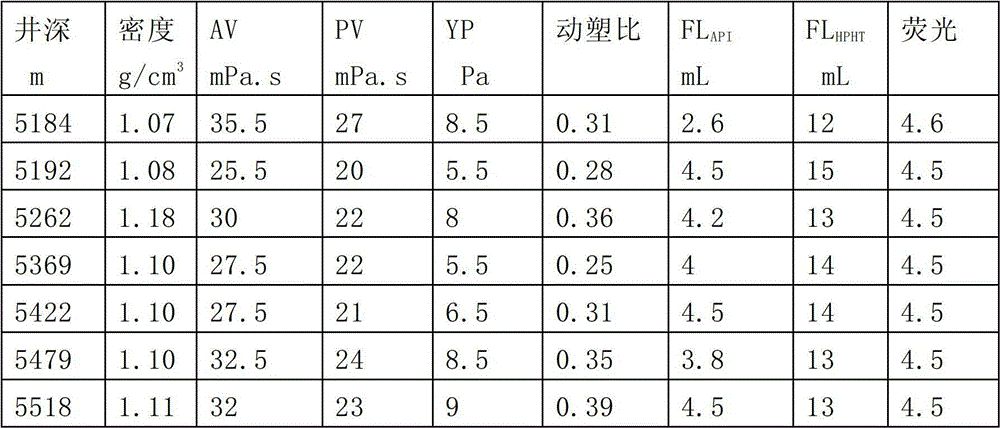

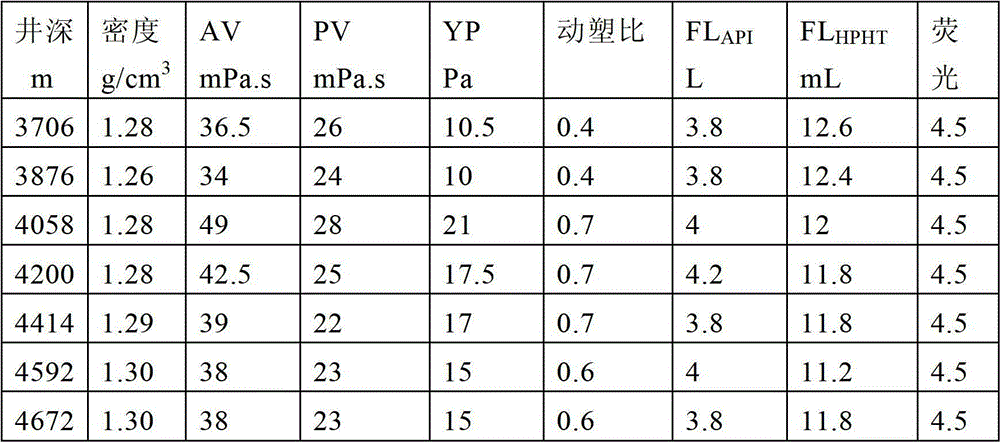

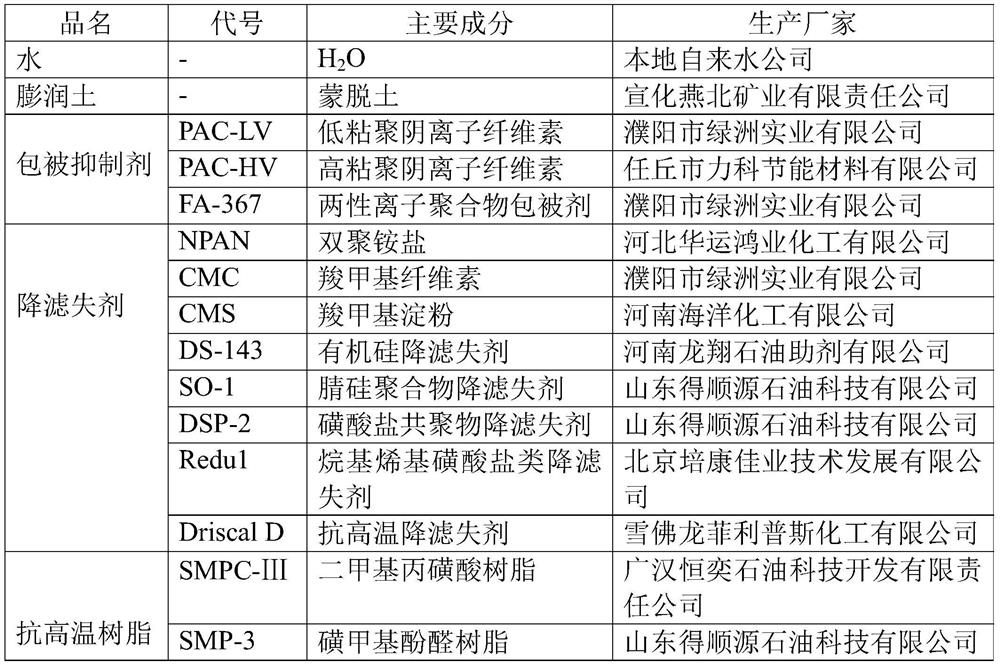

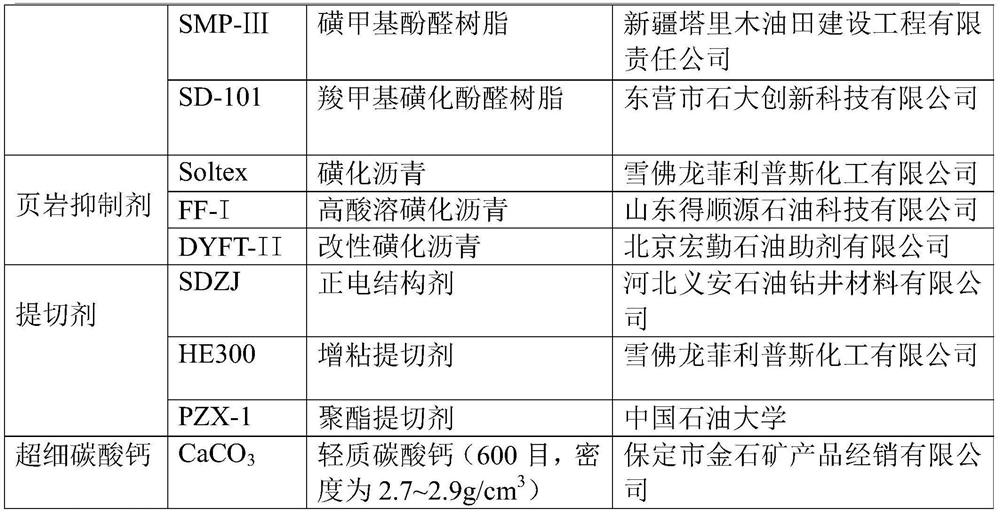

Low-solid phase ultrahigh-temperature water-based drilling fluid and preparation method thereof

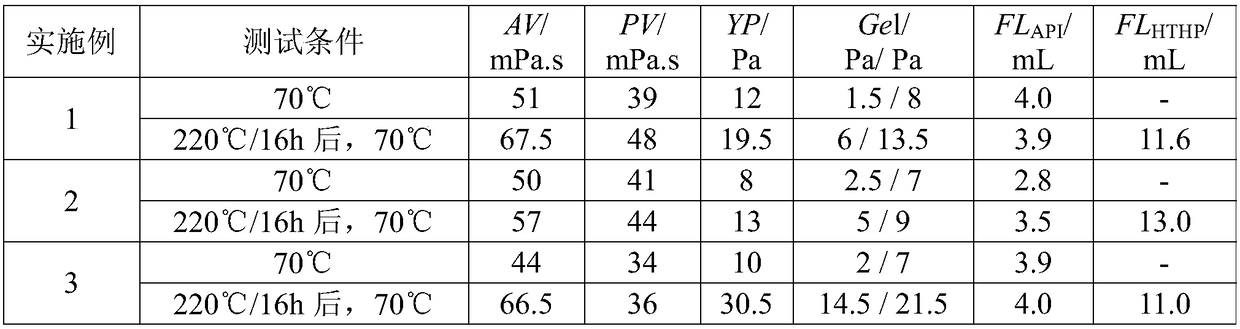

ActiveCN108949127AReduce pollutionImprove suspension abilityDrilling compositionWater basedRoom temperature

The invention discloses a low-solid phase ultrahigh-temperature water-based drilling fluid which is prepared from the following components in parts by weight: 100 parts of solvent water, 3-4 parts ofbentonite, 1.8-2.2 parts of a coating inhibitor, 2.3-3.5 parts of a filtrate reducer, 2-2.5 parts of high-temperature resistant resin, 2-2.5 parts of a shale inhibitor, 1.5-2 parts of a stripping agent and 15-35 parts of ultrafine calcium carbonate. The preparation method is simple. The preparation method comprises the following steps: adding a certain amount of bentonite into the solvent water toprepare prehydrated bentonite slurry; then successively adding the coating inhibitor, the filtrate reducer, the high-temperature resistant resin, the shale inhibitor, the stripping agent and ultrafine calcium carbonate while performing high-speed electric stirring; and finally, carrying out hydration at room temperature for 24 hours to prepare the low-solid phase ultrahigh-temperature water-baseddrilling fluid. The low-solid phase ultrahigh-temperature water-based drilling fluid can resist a temperature high up to220 DEG C, the low-solid phase ultrahigh-temperature water-based drilling fluidis good in rheological property, rock carrying property and high in blocking inhibiting property, the problem of low density carrying stability is solved, the low-solid phase ultrahigh-temperature water-based drilling fluid is successfully applied in mounting and probing a 4X well, and a good field application effect is obtained.

Owner:CNPC BOHAI DRILLING ENG +1

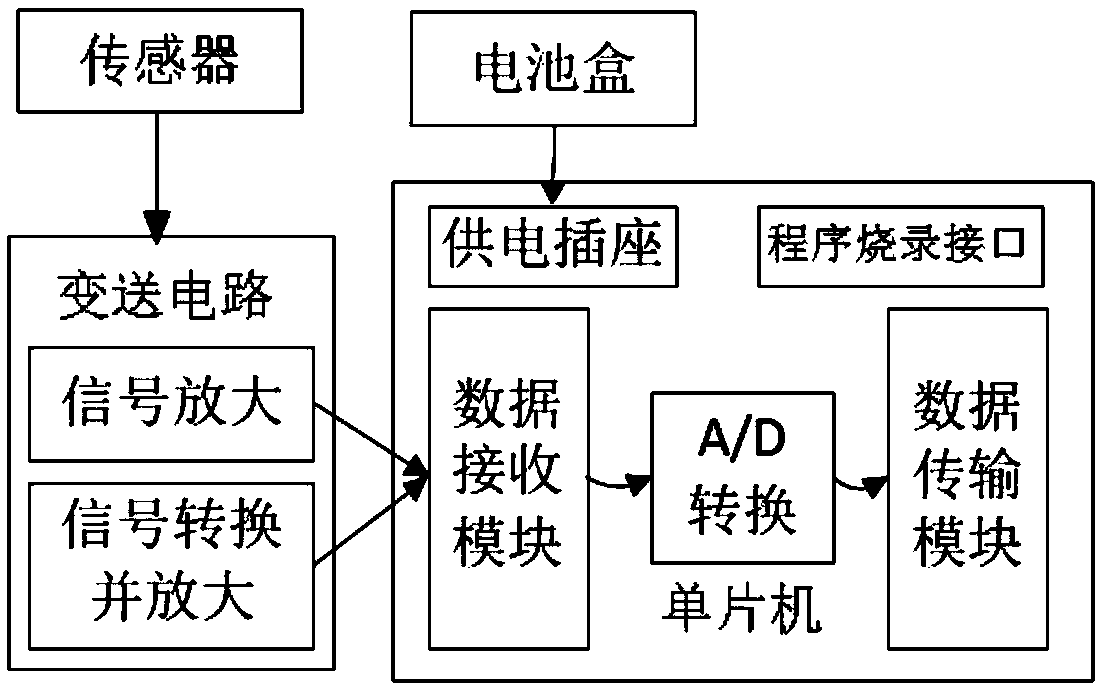

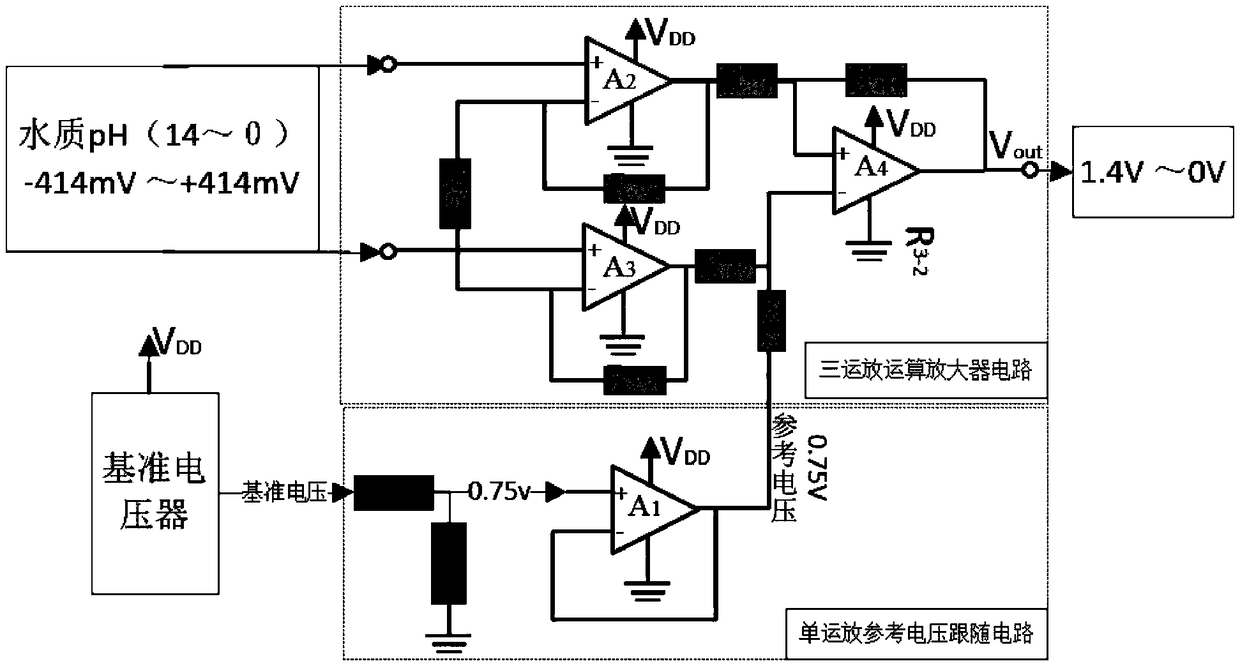

Ultralow-power-consumption pH signal conditioning transmission circuit and real-time water quality monitoring system

InactiveCN108627624AAchieve conversionAchieve improvementTransmission systemsTesting waterElectrical batteryWater quality

The invention discloses an ultralow-power-consumption pH signal conditioning transmission circuit and a real-time water quality monitoring system. The monitoring system comprises a pH sensor, a smalllightweight portable box, a lithium iron phosphate battery box, the pH signal conditioning transmission circuit, a single chip microcomputer, a data receiving module, an analog-digital conversion module and a data transmission module is arranged in the portable box. Under 3V power supply of a single power supply, power consumption of the pH signal conditioning transmission circuit can reach an ultralow state of 130mu A or less; furthermore, -414mV(ph=14) to +414mV(pH=0) weak water quality parameter signals monitored by the pH sensor can be correspondingly amplified to 1.4V to 0V, so that the real-time water quality monitoring system can reach ultralow power consumption, can be conveniently installed at different detection sites especially in inspection wells without achieving power supply,can be applied to monitoring whether sewage and wastewater meet a discharge standard and can report the abnormal water quality situations in time; thus, the problem that real-time collection cannot be achieved mutually in real life and the problem of long-time power supply of the system are solved, manpower resources are saved, and cost is reduced.

Owner:上海艾晟特环保科技股份有限公司

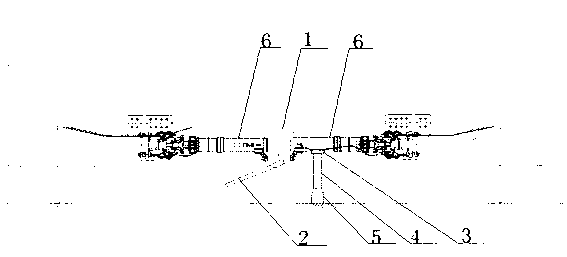

Car hook connecting and hanging method

InactiveCN102991527AReduce manufacturing costEasy to useRailway couplingsEngineeringAutomotive engineering

The invention discloses a car hook connecting and hanging method. The method is characterized by comprising the following steps of: connecting dragging points among cars by using a hoisting belt at one side of a car body, and stirring and pulling the cars to a car hook connecting and hanging distance by using a stirring roller; matching by using a jack, a supporting rod and a cushion block and jacking up the car hooks after the car hook distance reaches the connecting and hanging distance, continuously stirring the hoisting belt by using the stirring roller, so that the connected and hanged car hooks are tightly connected without gaps; and mounting connecting rings after the car hooks are jacked up to a horizontal state and no gap exists between two car hooks. The car hook connecting and hanging method has the advantages of low manufacture cost, convenience in use and good on-site using effect, saves time and labor and is safe and reliable.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

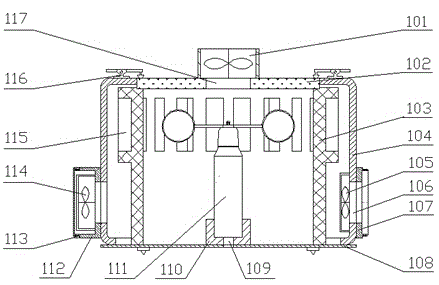

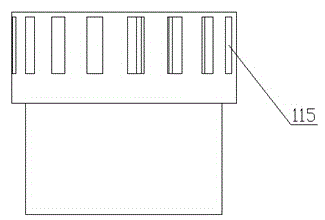

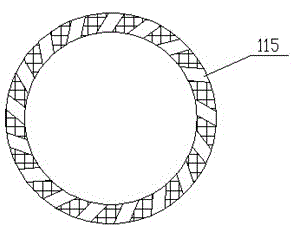

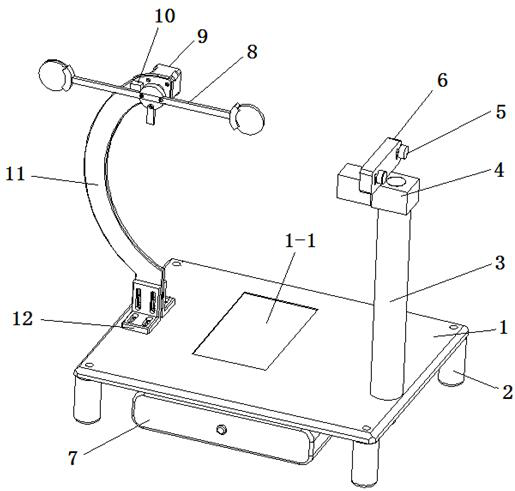

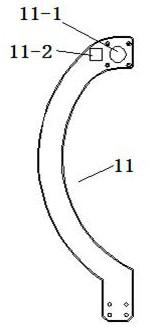

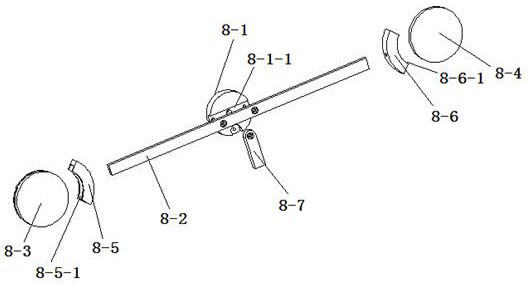

Automatic system for measuring starting and wind speed characteristics of cup type wind speed sensor

ActiveCN105137507AGuaranteed pass rateReduce volumeTesting/calibration of speed/acceleration/shock measurement devicesSystems designMeasurement cost

The invention discloses an automatic system for measuring starting and wind speed characteristics of a cup type wind speed sensor. The system includes a miniature wind tunnel generation device and a wind speed calibration instrument. The miniature wind tunnel generation device simulates wind speed of 0 to 10 m / s inside through a direct current fan to measure a starting wind speed characteristic and 0 to 10 m / s wind speed characteristics of the cup type wind speed sensor. The wind speed calibration instrument drives a wind speed sensor shaft to rotate through a driving device inside the wind speed calibration instrument to measure high wind speed section 10 to 40 m / s wind speed characteristics of the sensor. The system design has the characteristics of simple structure, small size, high measurement accuracy, good field use effect, lower measurement cost and the like. On the premise that appearance, rotation performance and a balance characteristic of a wind cup are qualified, through starting wind speed detection, an instrument whose resistance characteristic of the wind cup of the wind speed sensor is unqualified can be eliminated, repair is convenient, and the percent of pass of the instrument is guaranteed. After the starting wind speed detection is qualified, wind speed indicating value calibration is performed, thereby obtaining accurate wind speed characteristics.

Owner:ZHONGHUAN TIG TIANJIN METEOROLOGICAL INSTR

Low-fluorescence high temperature resistant drilling fluid

ActiveCN102676136BReduce high temperature and high pressure filtration lossImprove rheologyDrilling compositionFluorescenceWell drilling

A low-fluorescence high temperature resistant drilling fluid is applied to exploratory well drilling in high-temperature formations of deep wells. The drilling fluid comprises, by weight, 1.0-2.5% of a drilling fluid loss agent PAMS601, 2-4% of sulfonated methypheuo formald-ehyde, 4-8% of sulfonated lignite resin, 0.6-1.0% of di-n-dodecylamine, 0.1-0.5% of fatty alcohol-polyoxyethylene ether, 0.8-1.5% of Na2SO3, 0.1-0.3% of sodium alkyl benzene sulfonate and 30-90% of water. The low-fluorescence high temperature-resistant drilling fluid has the advantages that the fluorescence grade of the drilling fluid system is lower than Grade 5, the temperature resistant ability is above 200 DEG C, and the fluid can restrain formation mud making, improves stability of well walls, controls reservoir clay swelling and improves reservoir protection effects, besides, the fluid has the advantages of being stable at the high temperature, low in fluorescence and particularly applicable to deep well drilling.

Owner:PETROCHINA CO LTD

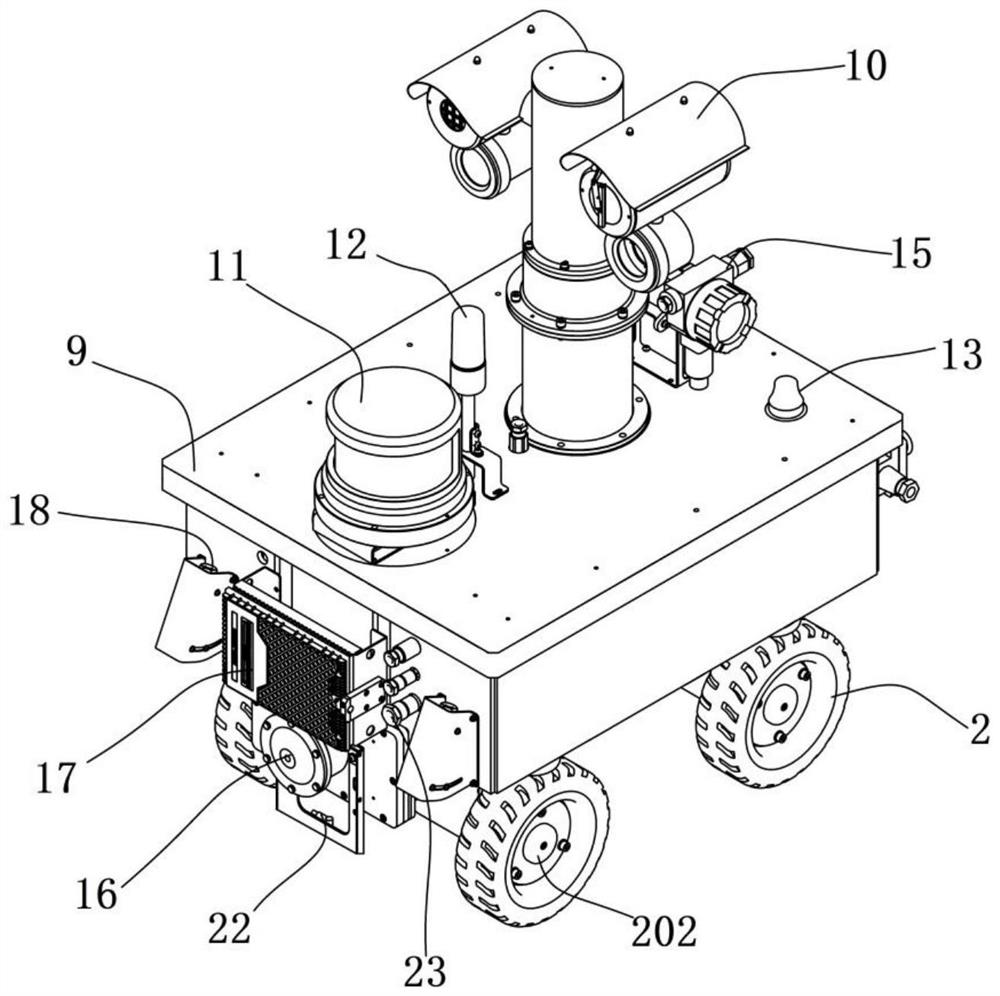

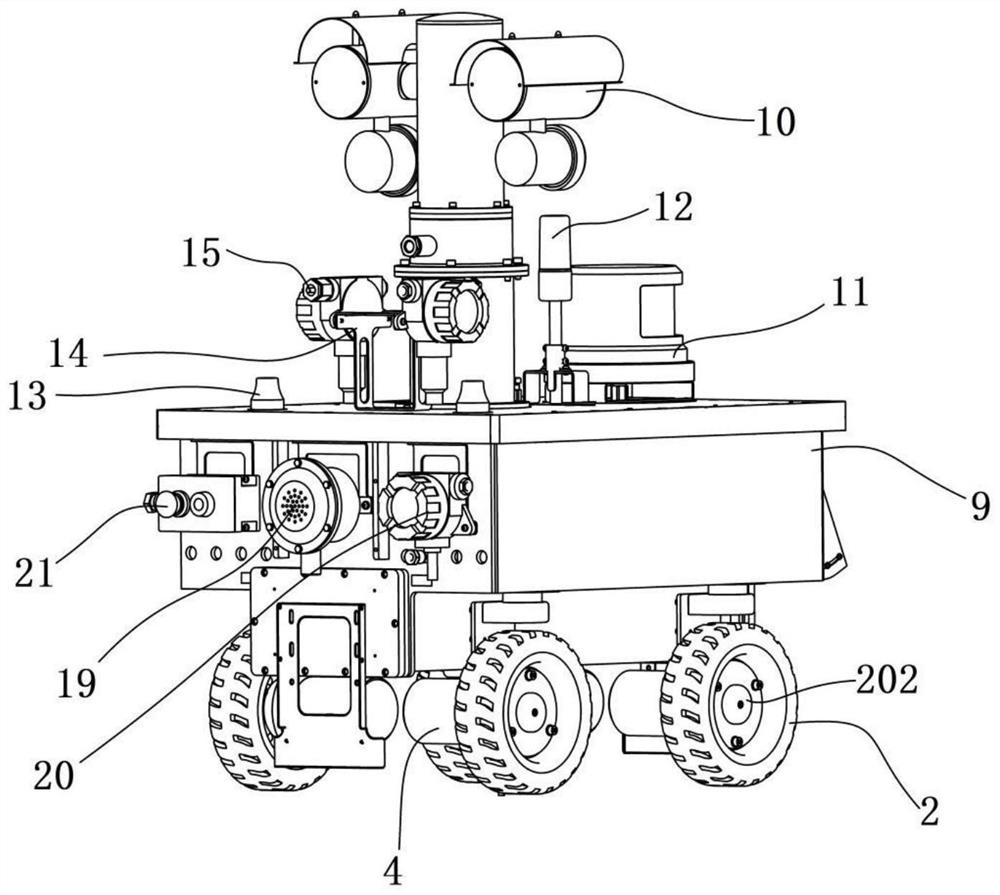

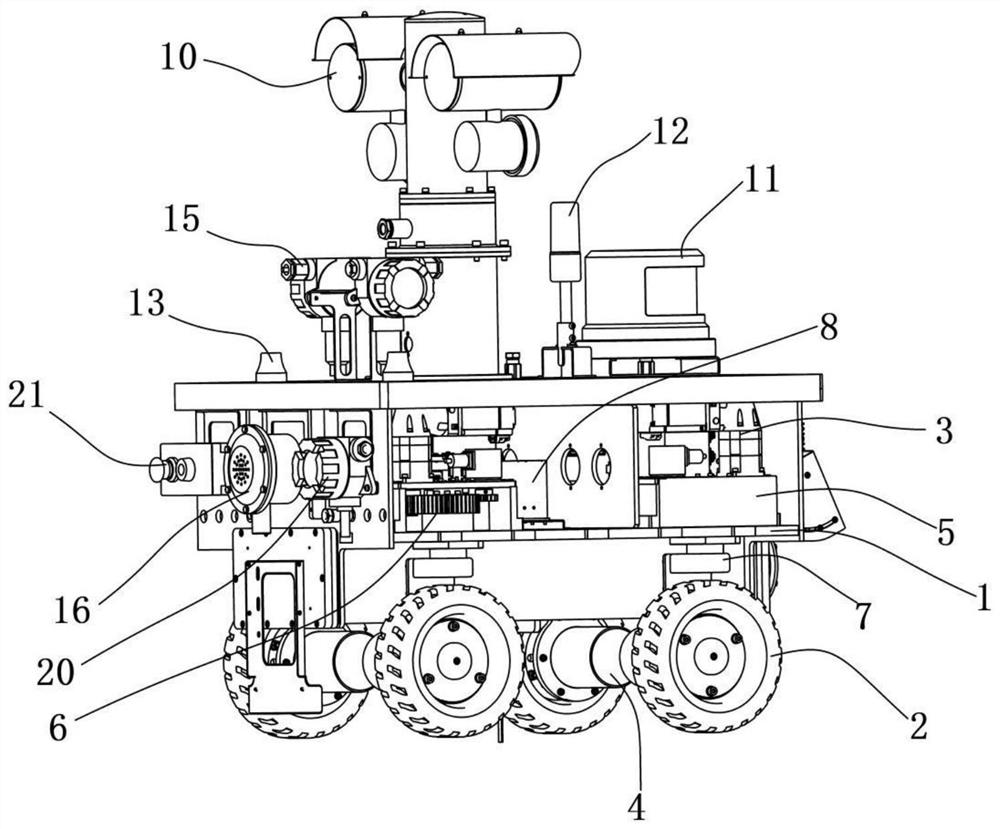

Chassis structure of inspection robot and inspection robot

The invention provides a chassis structure of an inspection robot and the inspection robot. The chassis structure of the inspection robot comprises a chassis and a driving wheel train fixedly installed on the chassis, wherein the driving wheel train comprises multiple sets of walking wheels and driving mechanisms in one-to-one correspondence with the multiple sets of walking wheels, and the walking wheels are correspondingly installed at the bottom end of the chassis; the driving mechanism comprises a first driving assembly for driving the walking wheels to rotate and a second driving assembly used for driving the walking wheels to go straight; the first driving assembly is fixedly installed on the top end face of the chassis through a supporting frame, the second driving assembly is connected with the fixing assembly through a gear mechanism, the fixing assembly penetrates through the chassis and is fixedly connected with the walking wheels, and the second driving assembly is perpendicular to the walking wheels. By adopting the four sets of walking wheels, each set of walking wheels is provided with one set of first driving assemblies for driving the walking wheels to rotate and one set of second driving assemblies for driving the walking wheels to go straight, actions such as turning can be easily completed, so that the robot has the advantages of being flexible in operation and wide in application range.

Owner:ZHEJIANG SUPCON TECH

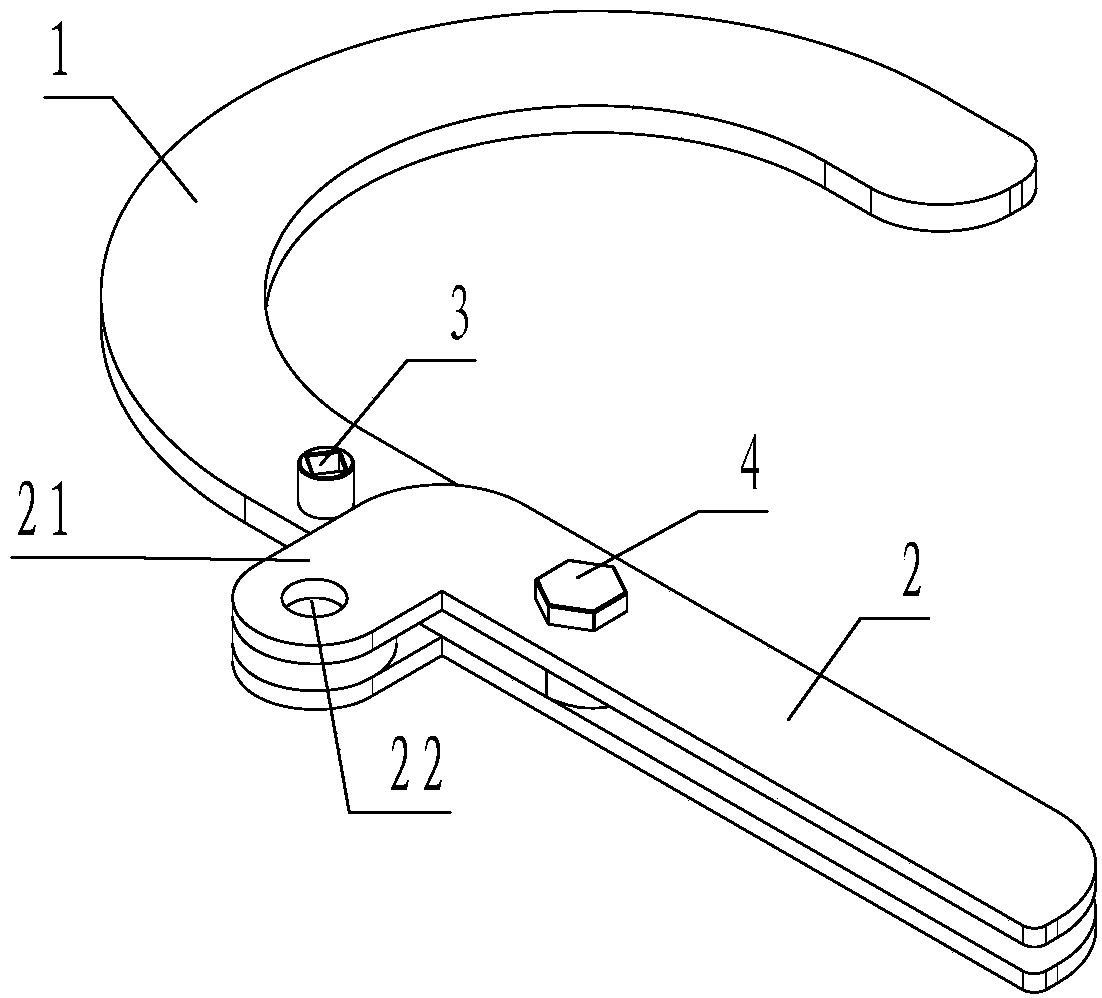

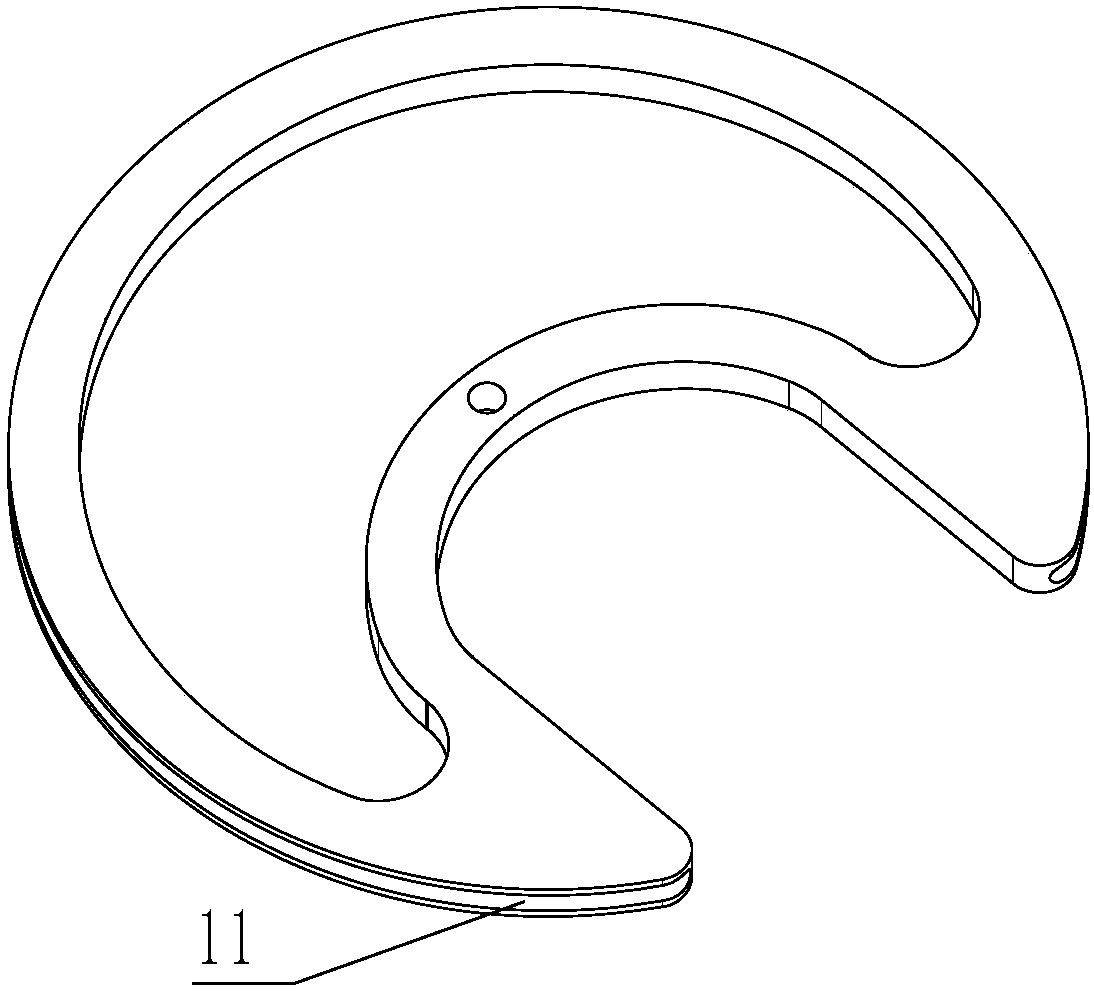

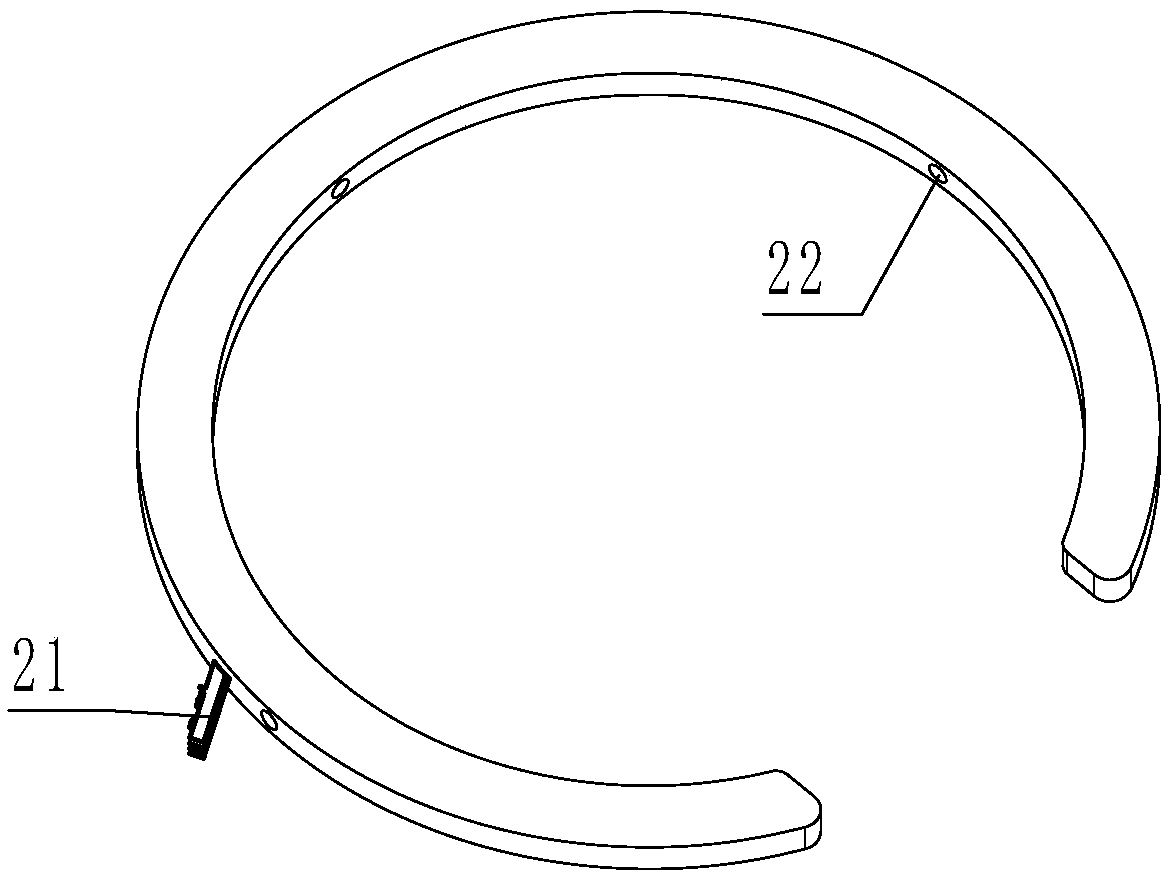

Method of mounting felling traction rope

The invention discloses a method of mounting a felling traction rope, comprising: in order to mount a traction rope, fixing the traction rope to a traction rope fixing hole, mounting a wabbler to a fixed connector, mounting an insulating operating rod to the wabbler, using the insulating operating rod to extend a hoop of the felling traction rope above the center of gravity of a tree so that the hoop is automatically adjusted in size to clamp a trunk, rotating anticlockwise to remove the insulating operating rod, and continuously tensioning the traction rope so that the center of gravity of the tree is slightly shifted before felling can be begun. The method has the advantages that carrying is convenient, operating is simple, the traction rope can be fixed on a ground just through the insulating operating rod, climbing in wet slippery woods is avoided, safety and convenience are high, field service effect is significant, and expected objectives are achieved.

Owner:FUZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +1

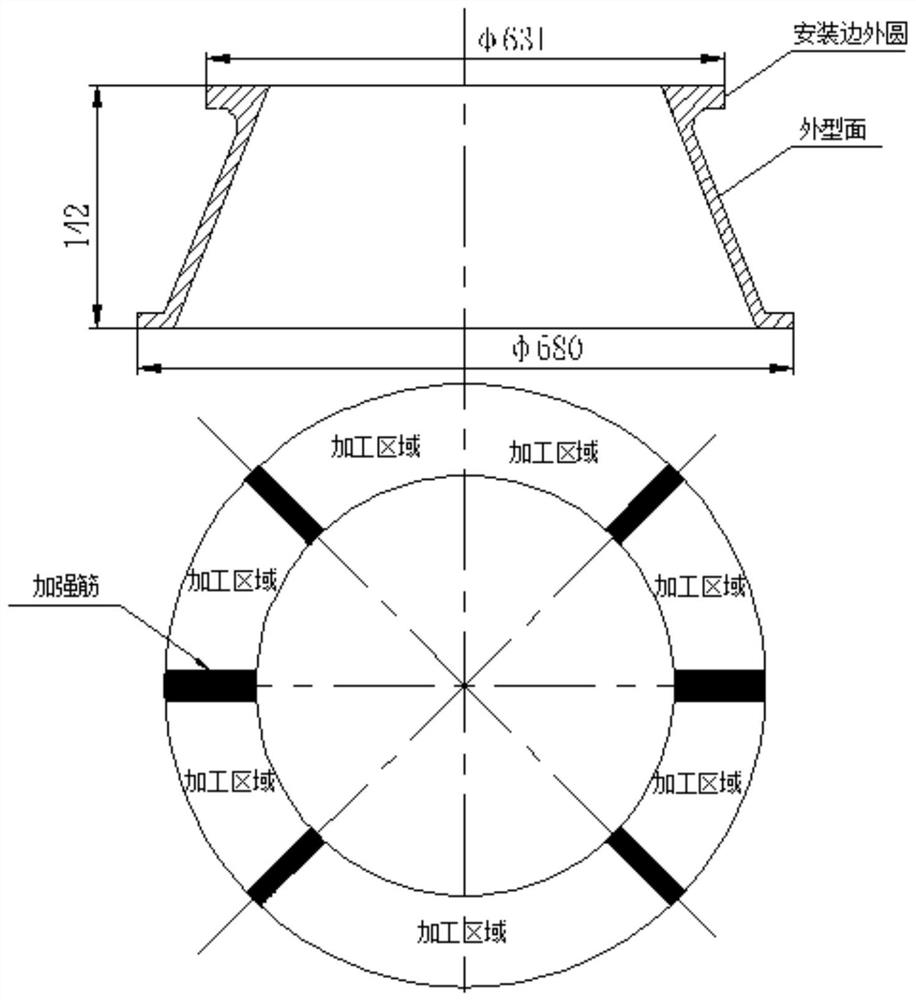

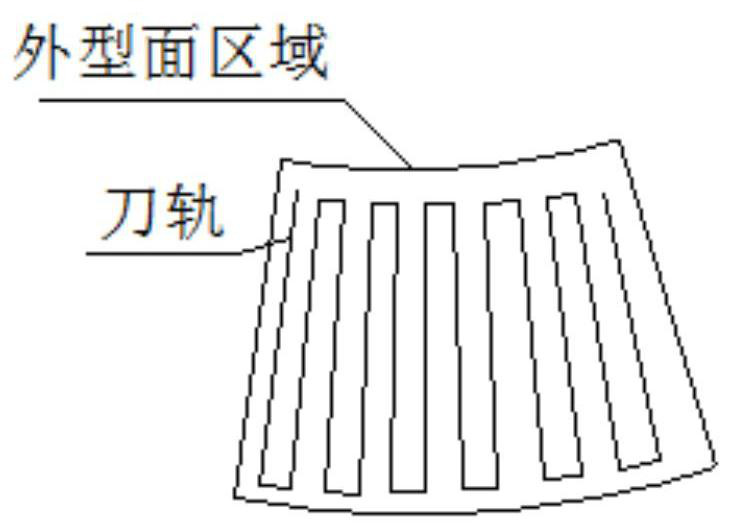

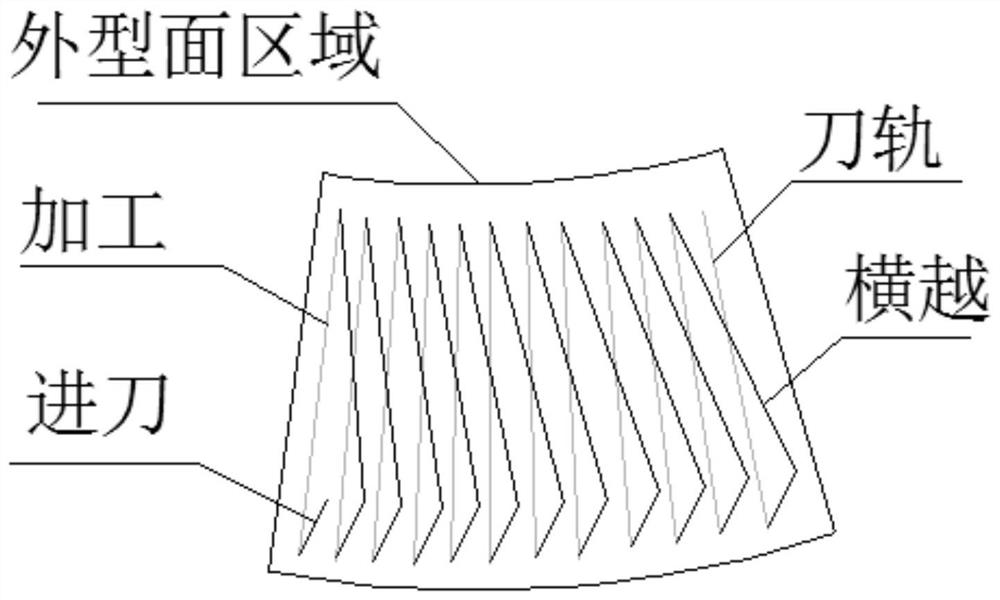

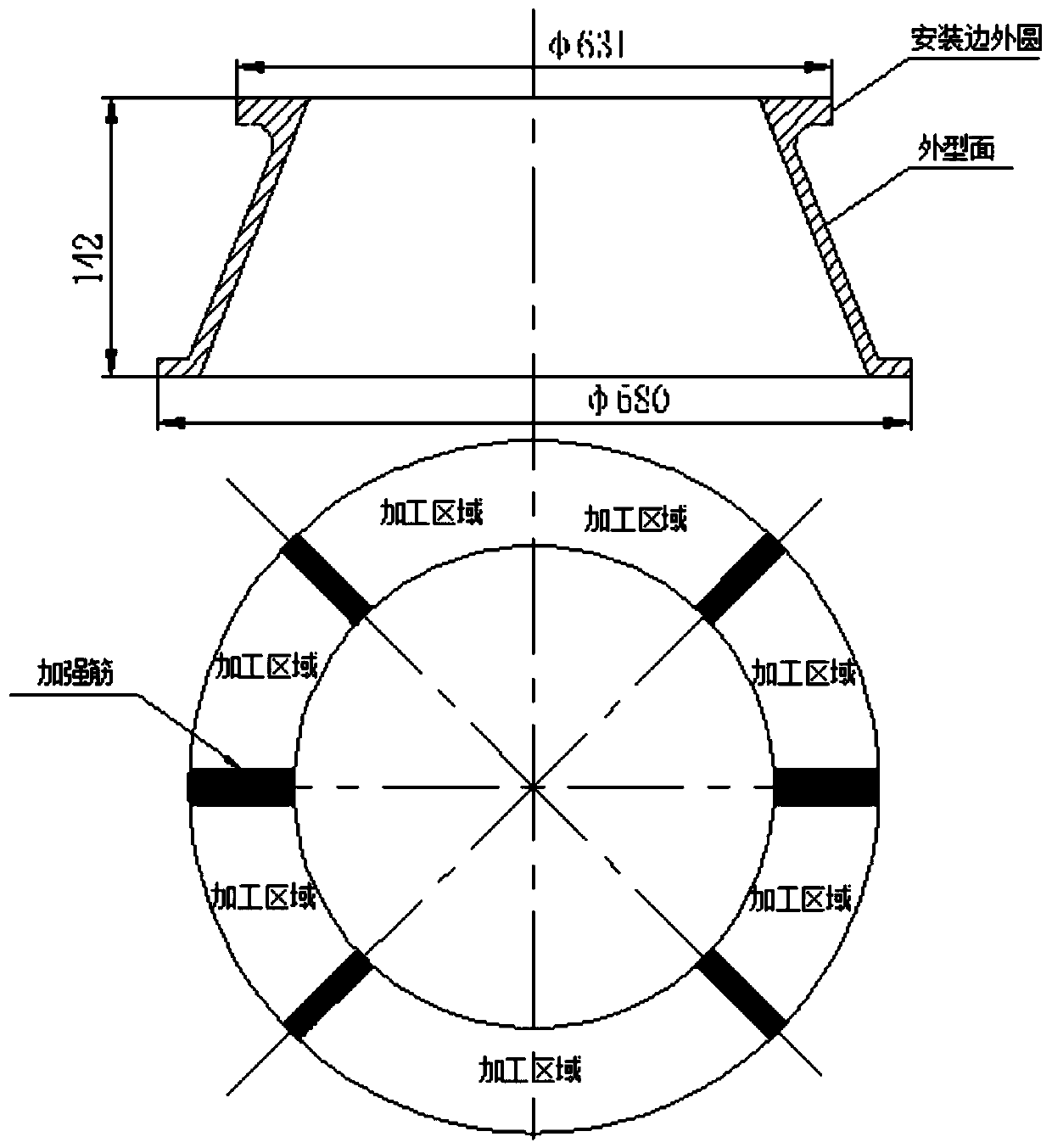

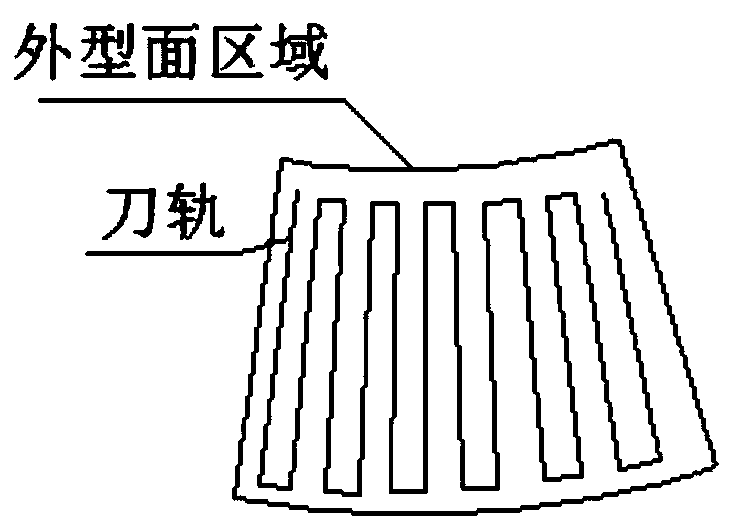

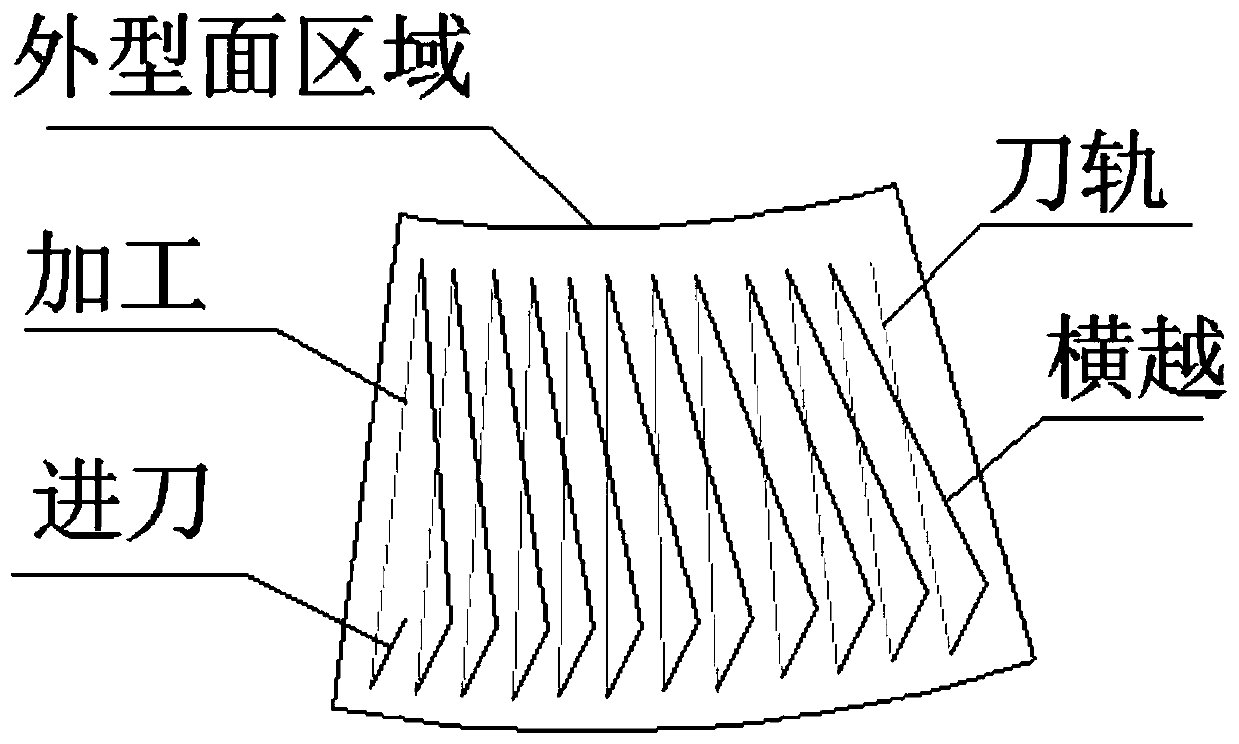

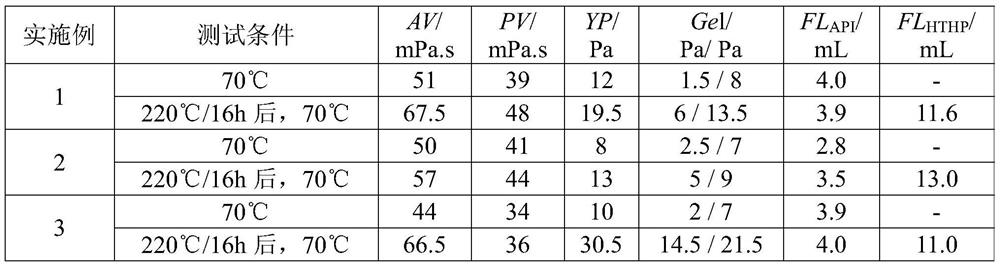

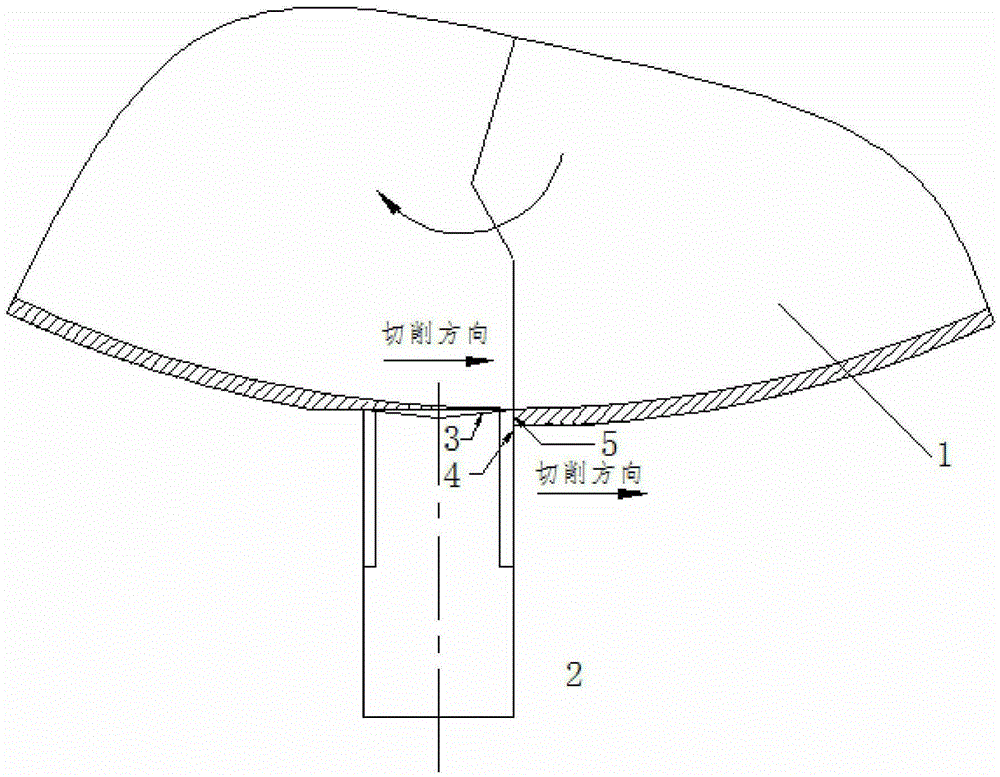

A processing method for adaptive milling of the outer surface of the casing

ActiveCN110899782BImprove milling efficiencyImprove surface qualityAutomatic control devicesFeeding apparatusEconomic benefitsProcess engineering

A processing method for adaptive milling of the outer surface of the opening case, determining the trajectory planning of the adaptive milling process for the outer surface of the opening case, determining the online measurement trajectory planning of the outer surface of the opening case, and generating a strip with a software post-processing method. Machining programs with adaptive milling compensation variables. Determine the machining path planning of adaptive milling tool. The tool path is changed from the longitudinal reciprocating mode to the longitudinal single mode, and from the original forward and reverse milling alternate milling to all the forward milling mode, which improves the cutting force of the tool during processing, and improves the processing efficiency and surface quality. The invention has the advantages of significant economic benefits, increased milling efficiency by more than 20%, qualified wall thickness, and improved surface quality by one grade. Under the premise of ensuring the processing quality of the parts, the milling processing time can be shortened, the processing efficiency can be improved, and the wall thickness and size requirements can be guaranteed. The processing quality of the parts is stable, and the processing efficiency is obviously improved, and it can be extended to the external milling of other opening casings.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

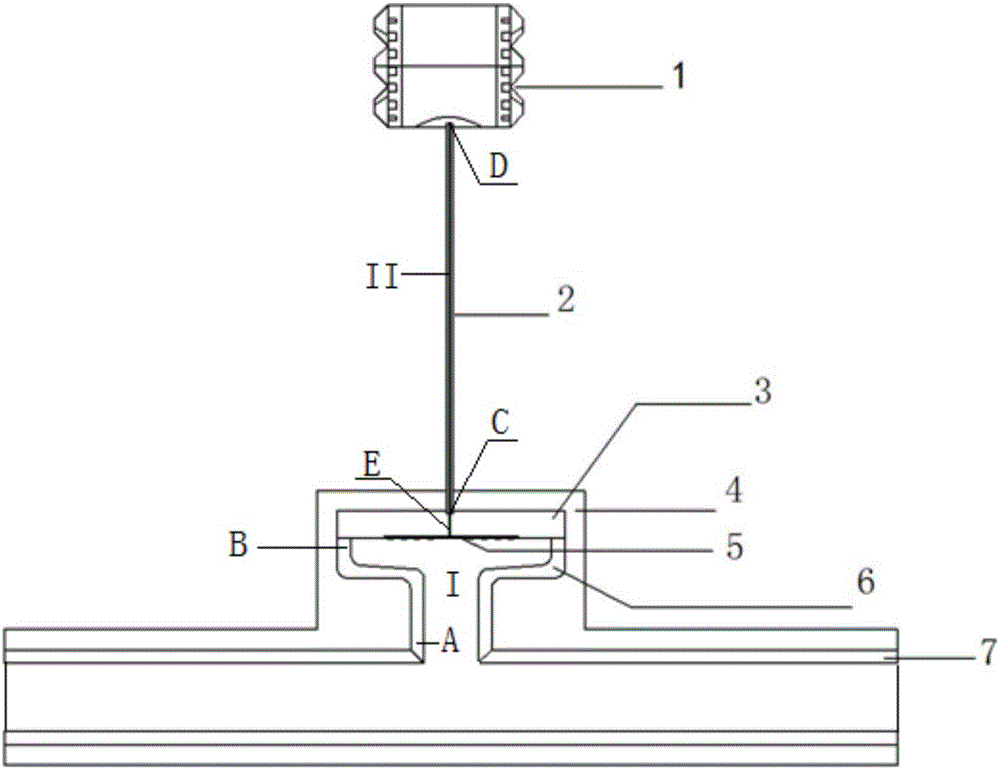

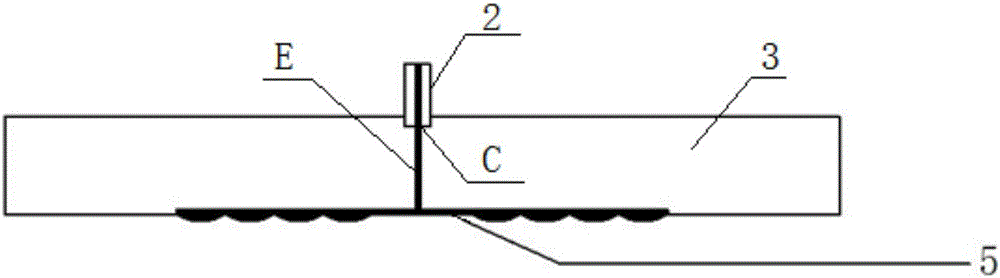

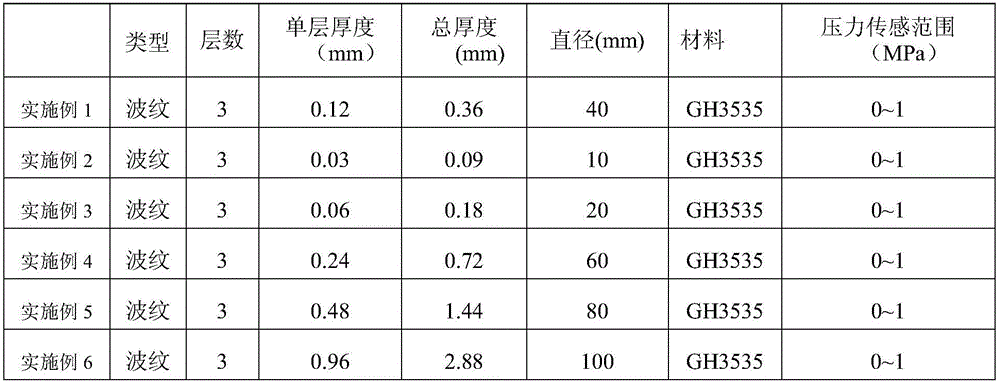

High-temperature villiaumite pressure meter

ActiveCN105865701AHigh precisionHigh sensitivityFluid pressure measurement using elastically-deformable gaugesPressure transmissionBoiling point

The invention discloses a high-temperature villiaumite pressure meter, and the meter is used for measuring the pressure of fluid. The pressure meter comprises a pressure transmitter, and is characterized in that the pressure meter also comprises a pressure transmission device which is provided with a first cavity and a second cavity; the first and second cavities are respectively provided with an opening end, and are separated by a membrane; the opening end of the first cavity is used for the sealing connection with the cavity where the fluid is located; the opening end of the second cavity is in sealed connection with the pressure transmitter; and the interior of the second cavity is provided with a medium for transmitting pressure. The pressure meter provided by the invention can employ high-temperature resistant anticorrosion materials to form the first cavity and the membrane, employs a low-melting-point and low-boiling-point material to serve as the medium for transmitting the pressure in the second cavity, and thereby can be used for the pressure measurement of the high-temperature highly corrosive fluid (villiaumite).

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Composite metal ceramic powder, furnace roller coated with same and preparation method thereof

ActiveCN101838767BImprove compactnessImprove structural uniformityMolten spray coatingChromium carbideSurface layer

The invention discloses a composite metal ceramic powder, a furnace roller coated with the same and a preparation method thereof. The composite metal ceramic powder contains the following components in percentage by weight: 35-70 percent of MCrAlY or MCrAlTaY, 25-45 percent of Cr3C2 and 5-20 percent of Na2Ti6O13 or K2Ti6O13, wherein M is Ni, Co or Ni-Co alloy. The furnace roller comprises a workpiece substrate and a coating sprayed on the workpiece substrate, wherein the coating comprises a surface layer and a bottom layer or a single surface layer, and the surface layer is made of the composite metal ceramic powder. The furnace roller is prepared by adopting a high-speed oxygen flame spraying method and has excellent heat resistance, wear resistance and nodule resistance performances and average service period reaching over 2 years.

Owner:BAOSHAN IRON & STEEL CO LTD

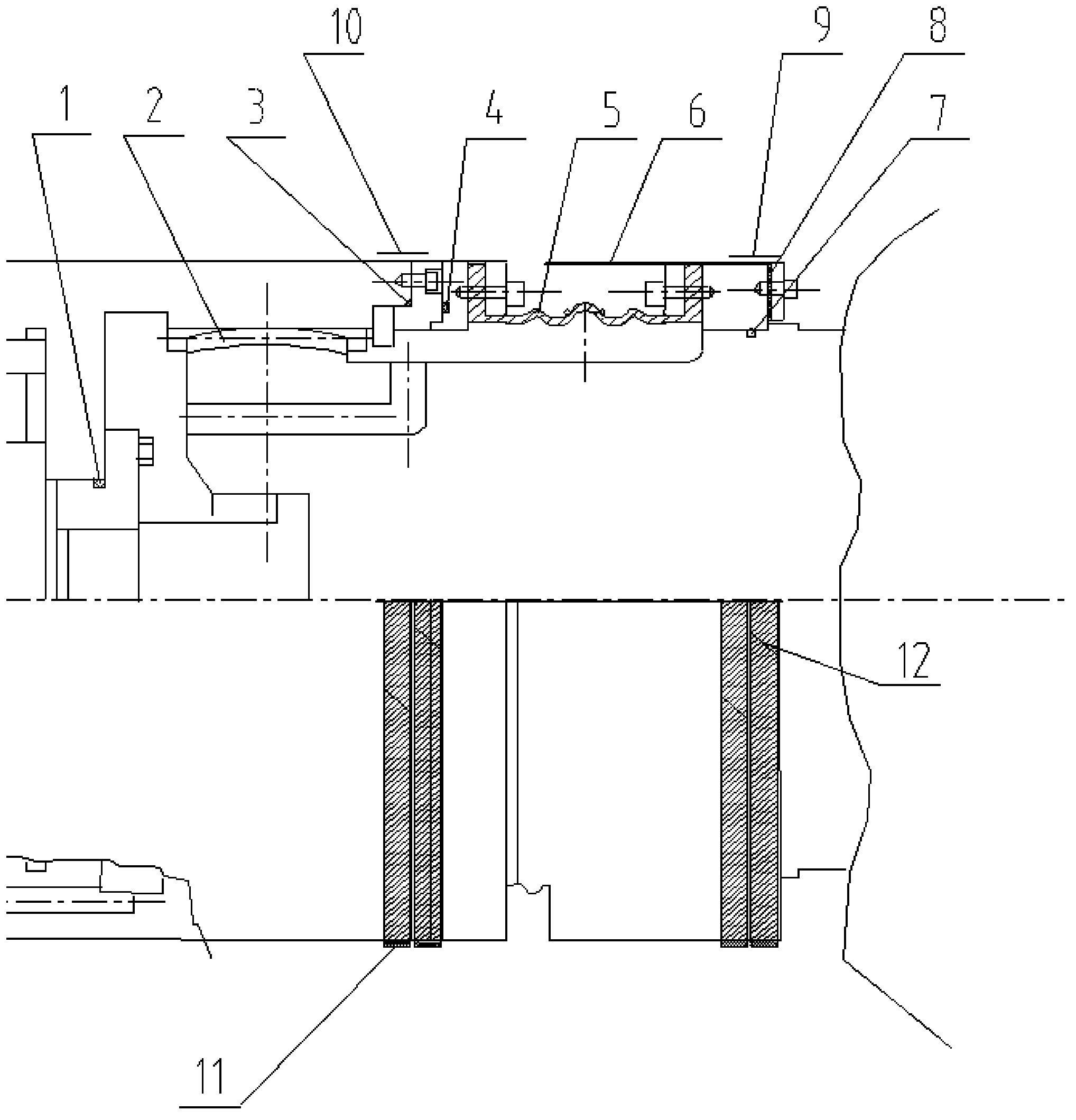

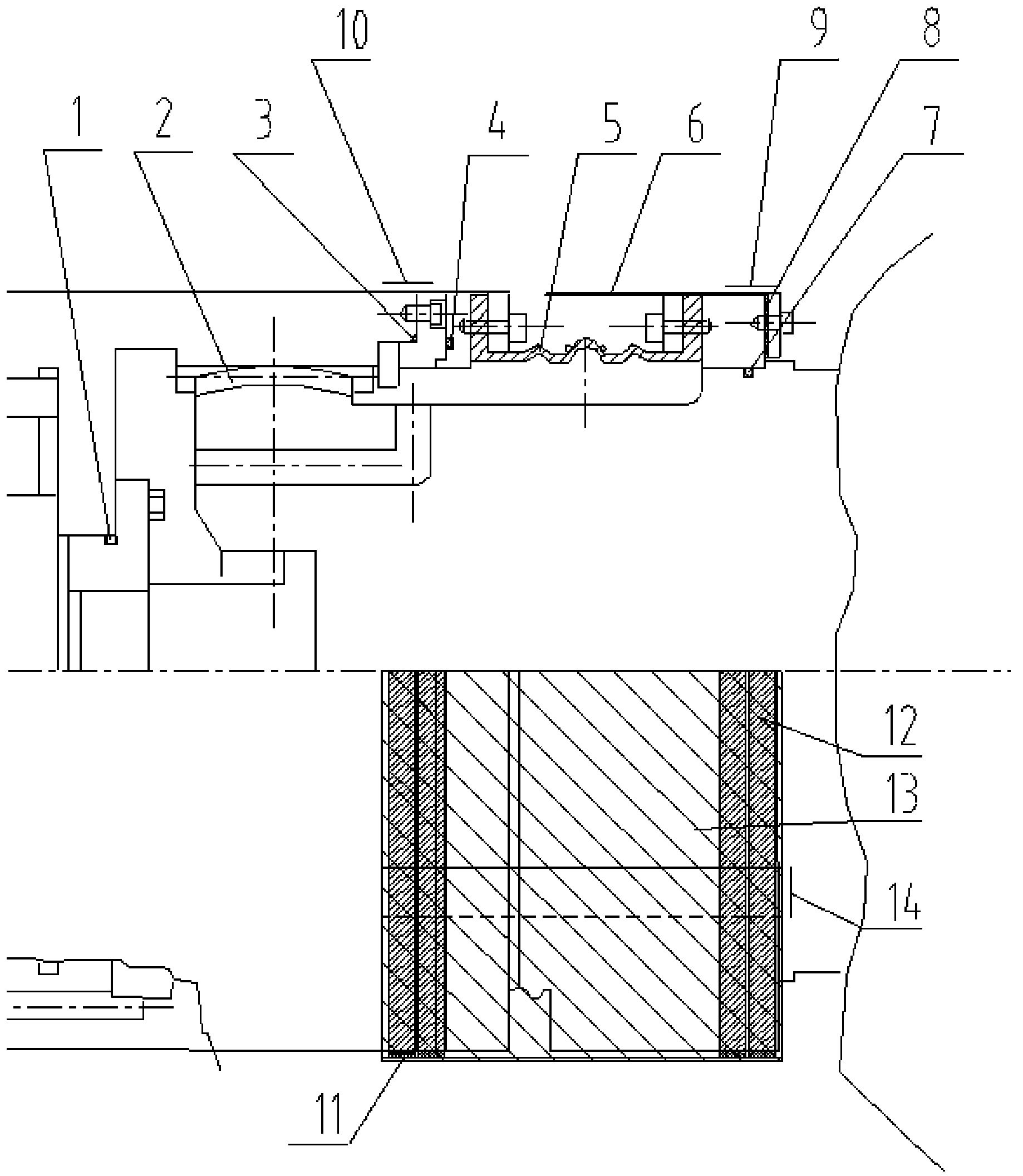

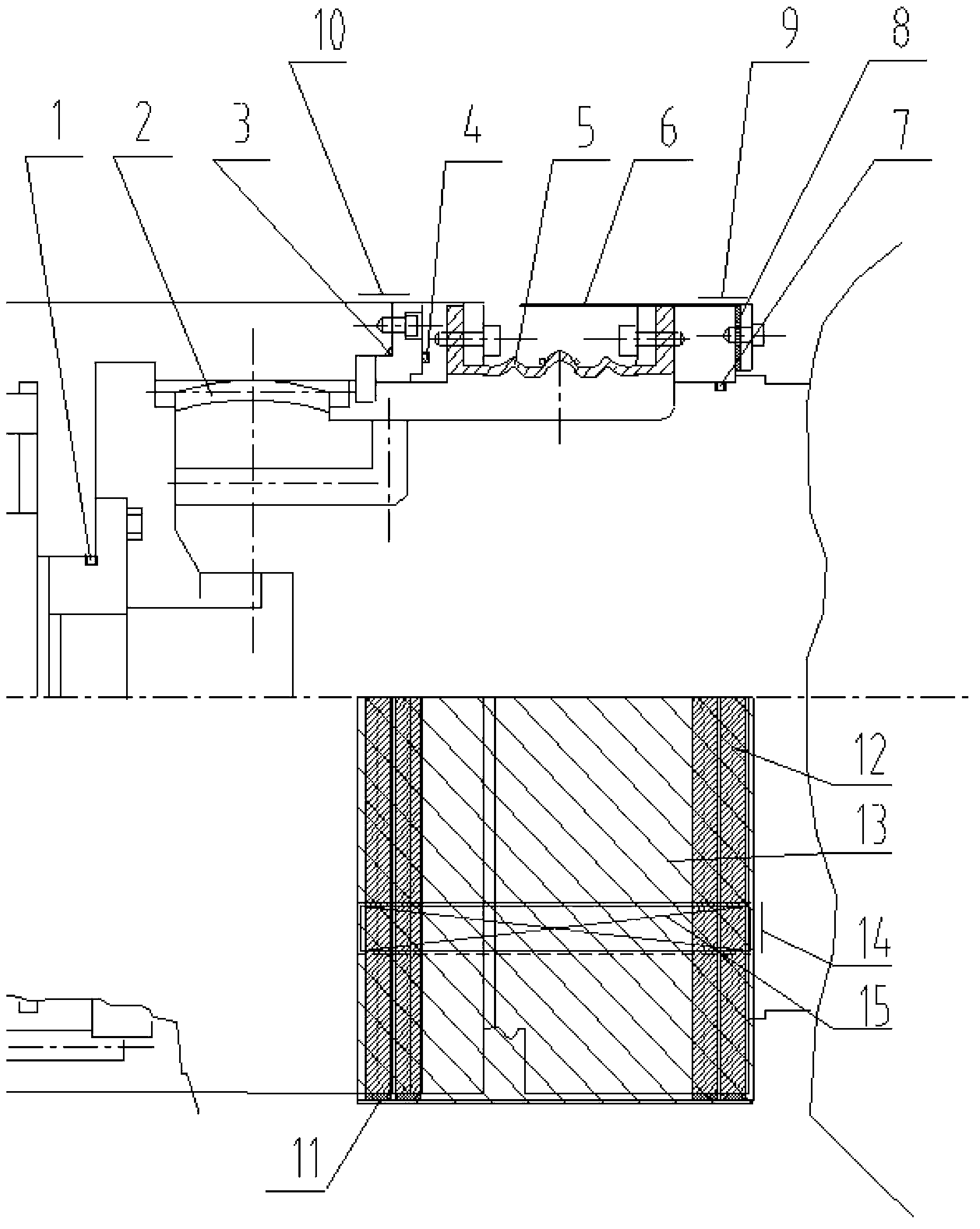

Rapid plugging method used for oil pocket for lubricating crown gear transmission shaft in high-speed rotating state

The invention provides a rapid plugging method used for an oil pocket for lubricating a crown gear transmission shaft. The oil pocket is an oil pocket used for lubricating the transmission shaft, and a barrel-shaped oil pocket protective cover is arranged at the periphery of the oil pocket. The rapid plugging method is characterized by comprising the following steps: (1) installing a rubber gasket at a fastening bolt on the side surface of the oil pocket protective cover to prevent lubricating oil from leaking from the part after plugging; (2) cleaning the transmission shaft along the circumferential direction of the transmission shaft by using a detergent; (3) taking a sealing tape with a single side being adhesive, winding the sealing tape on the circumferential surface (9) of the oil pocket protective cover and the circumferential surface (10) of a flat head sleeve along the circumferential direction of the transmission shaft to form a closed ring at the parts; (4) winding and bonding a rubber sheet with the middle provided with a reinforcing material on the sealing tape, and overlapping interfaces of the rubber sheet. The field application effect is good, and the promotion prospect is good.

Owner:BAOSHAN IRON & STEEL CO LTD

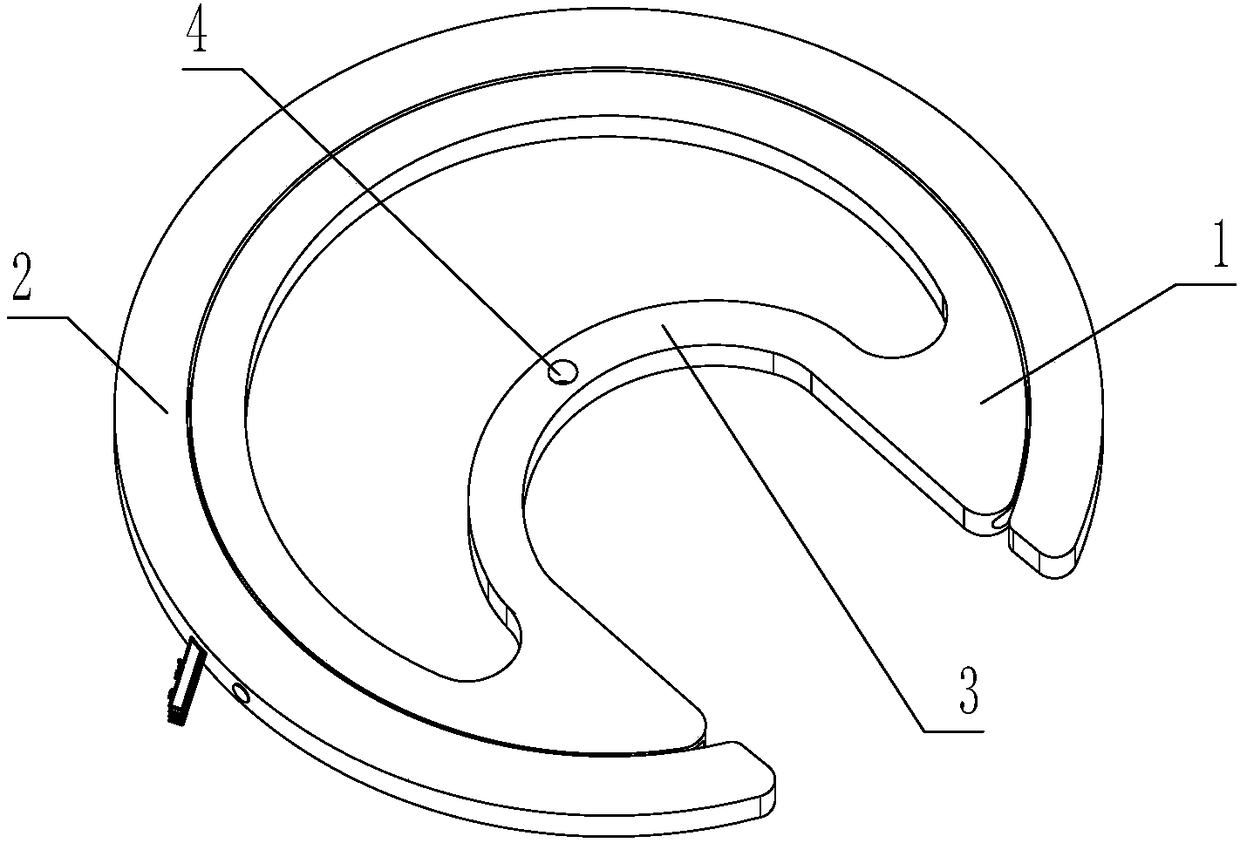

Rope winding device

The invention discloses a rope winding device. The rope winding device comprises an inner ring and an outer ring with openings, wherein the external ring of the inner ring is sleeved by the outer ring, the inner ring rotates relative to the outer ring, and the inner ring further comprises a small ring; two end points of the small ring start from both sides of the opening in the inner ring, the small ring shares the same opening with the inner ring, and a fixing hole for fixing a traction rope is formed in the small ring; the outer ring is provided with a connection device for connection with an insulating operation rod. The rope winding device has the advantages of convenient carrying and simple operation, and fixing of the traction rope can be completed by leading the traction rope to theground only through the insulating operation rod, so that climbing operation in a sloppy forest is avoided, the safety and convenience are very high, the effect of on-site use is very significant, the overall process is completed within only 3 minutes, and the work efficiency is increased by 5 times; simply carrying of a telescopic insulating operation rod of less than 1.5 meters long and an auxiliary tool with a diameter of less than 300 mm is needed, and transport and carrying are extremely convenient, especially in a thick forest.

Owner:FUZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +1

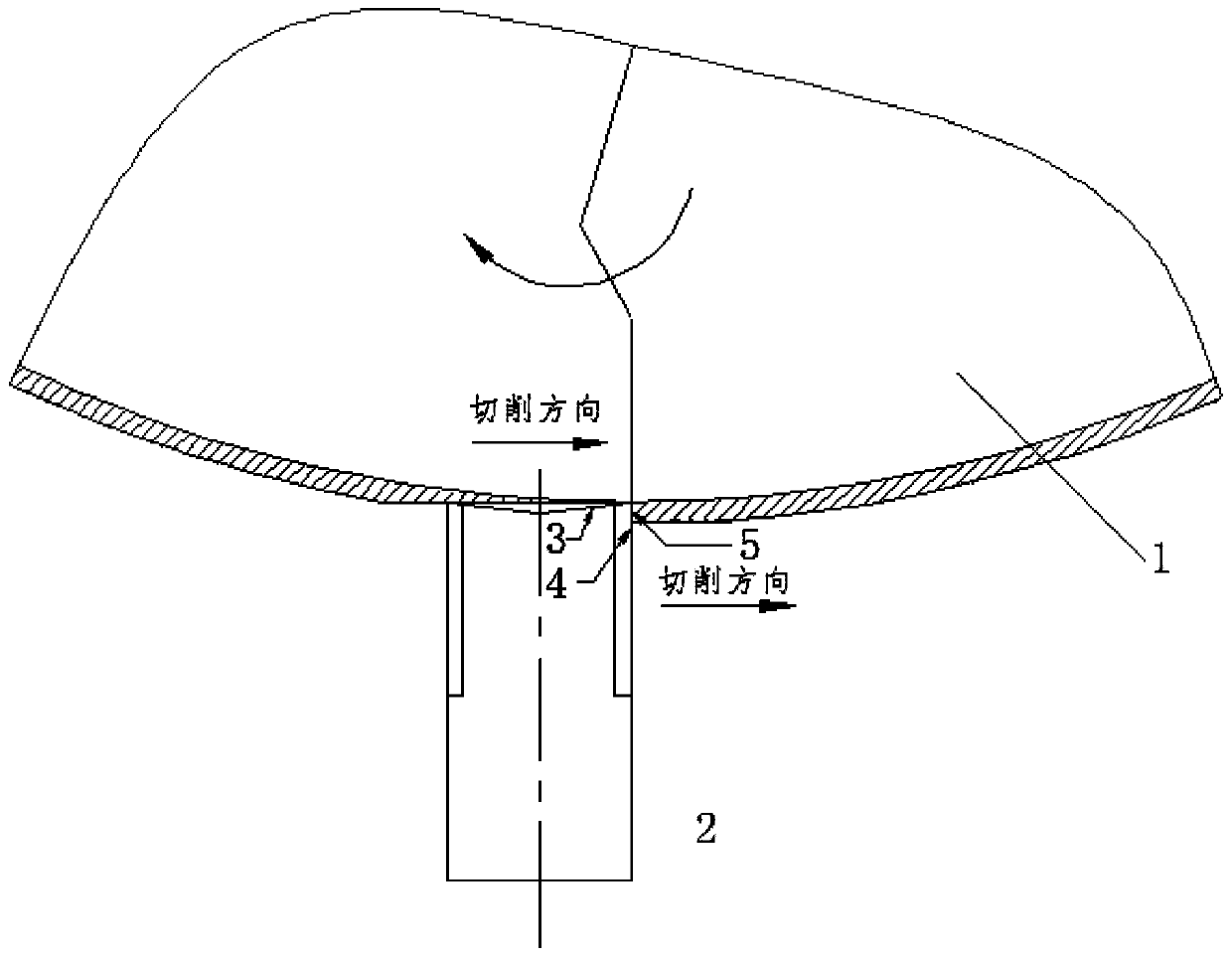

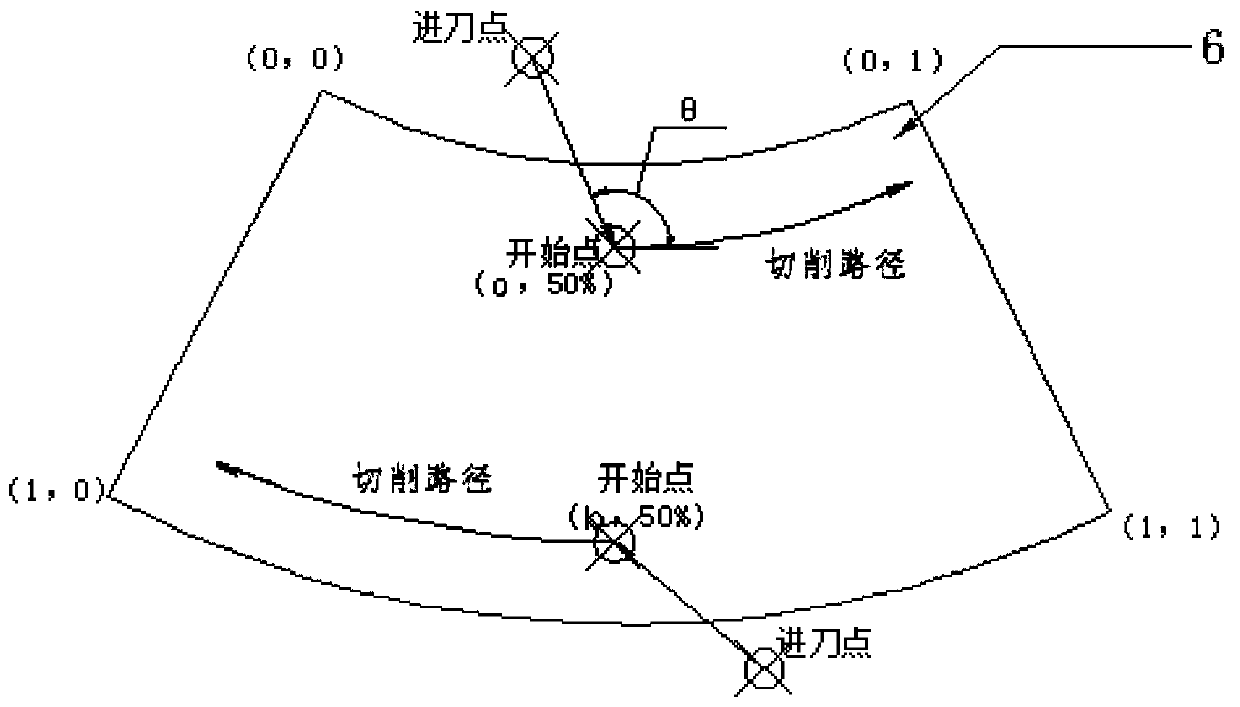

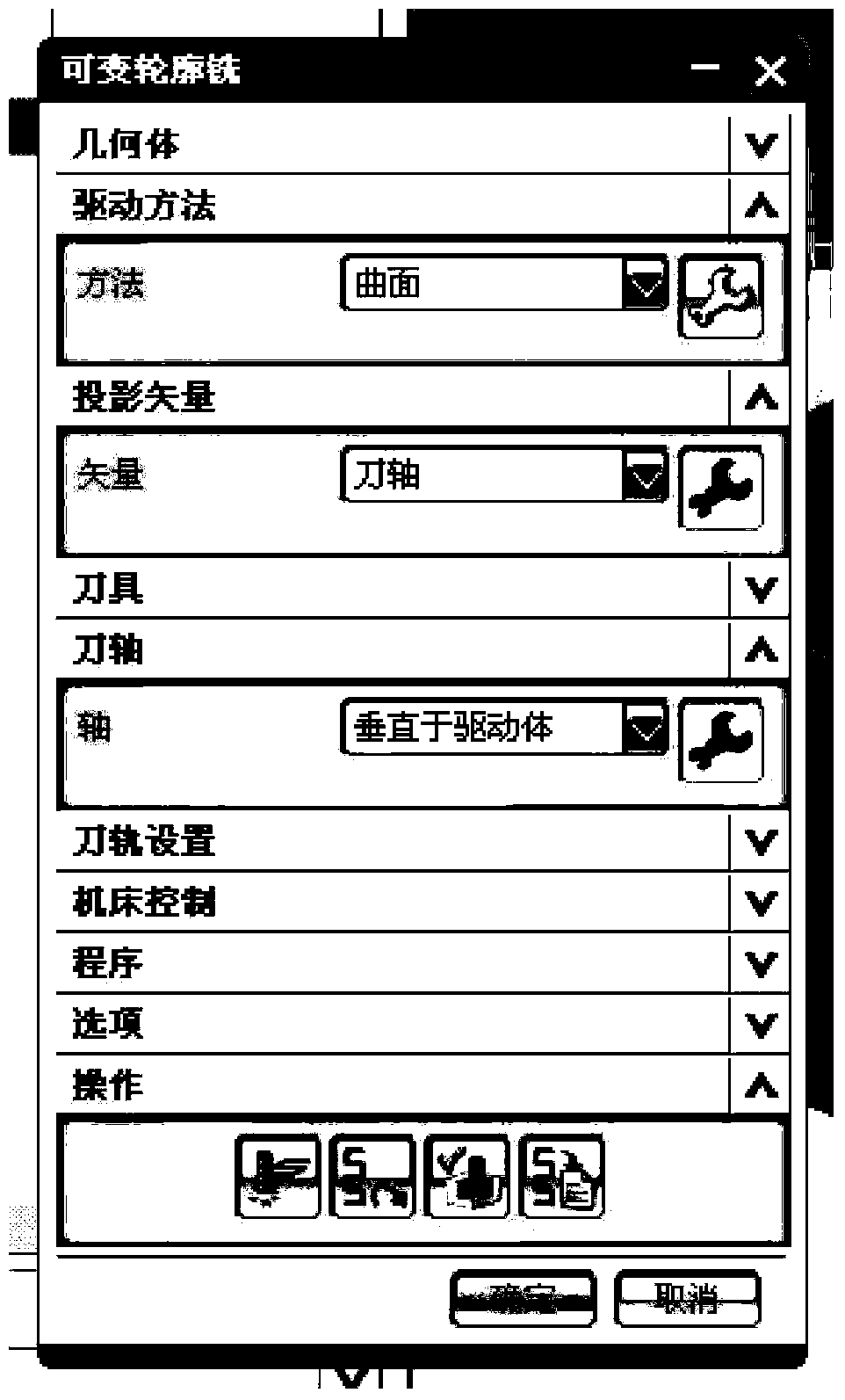

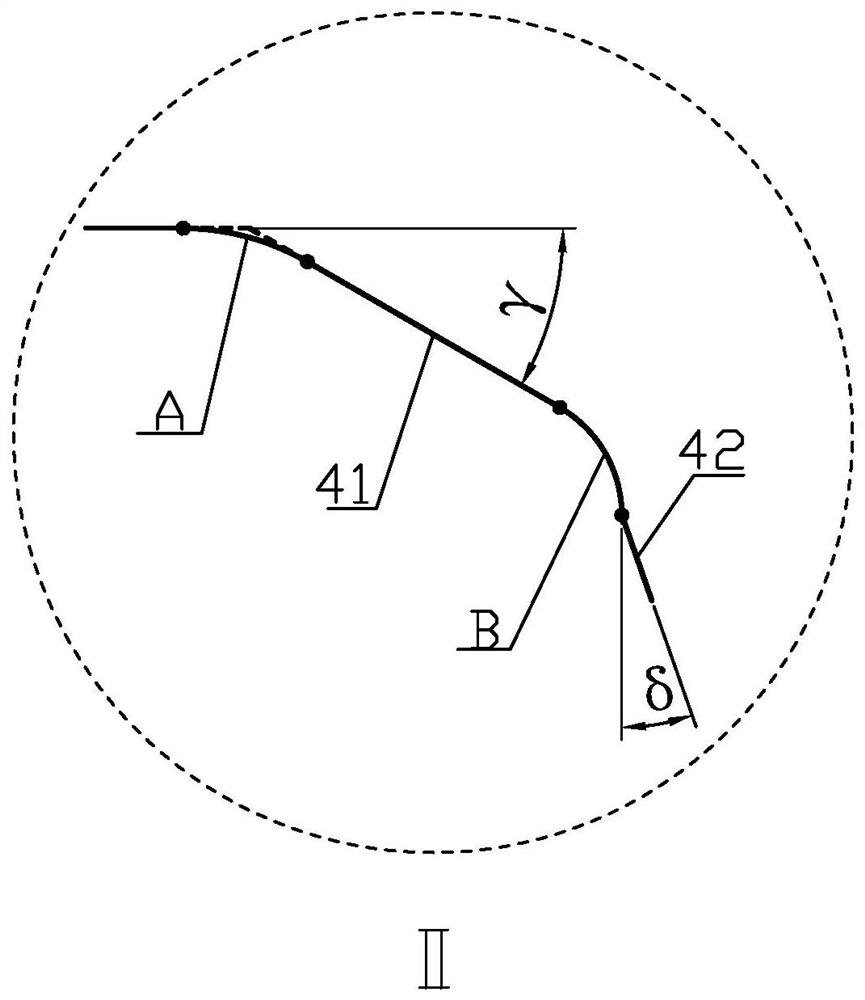

A Machining Method for Offset Milling of Conical Outer Surface of Case

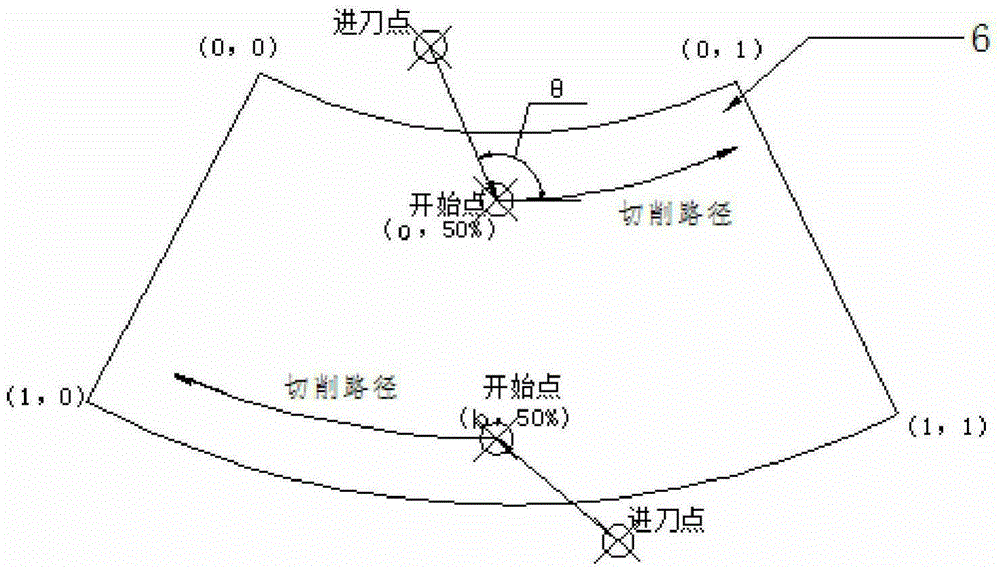

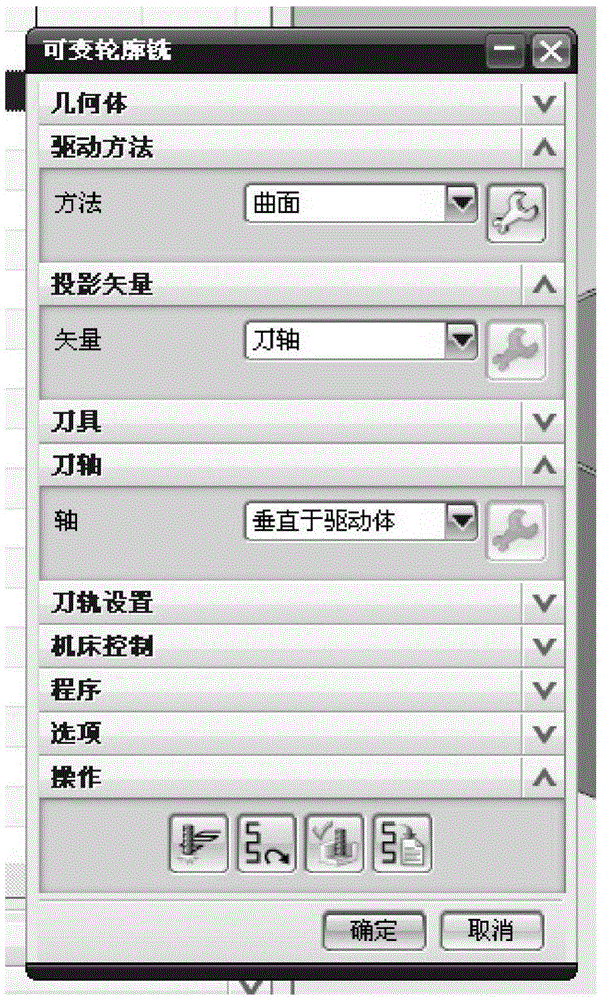

ActiveCN105290473BSolve the problem of CNC millingImproved cutting angleMilling equipment detailsMachine toolFeed point

The invention relates to a processing method for offset milling of the cone-shaped outer surface of the casing. The following steps are as follows: using UG software to prepare the milling operation of the cone-shaped outer surface of the casing; planning the milling sequence and cutting tools for the cone-shaped outer surface of the casing track; customize the special post-processing program of UG software; use the special post-processing program to create the G code program recognized by the machine tool; plan the milling sequence and tool trajectory of the outer surface of the cone of the casing as follows: the outer surface of the cone of the casing is divided into Several surface areas, each surface area is used as a separate driving body, and each surface area is represented by (U, V) parameters; the feed point is selected in the middle of a single surface area, and the angle θ between the feed direction and the cutting direction is greater than 90 °, less than 270. The invention improves the cutting angle of the tool, increases the cutting range of the side edge, and reduces the cutting of the bottom edge, thereby reducing the wear of the tool, improving the processing efficiency, and successfully solving the problem of numerical control milling on the cone-shaped outer surface of the casing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

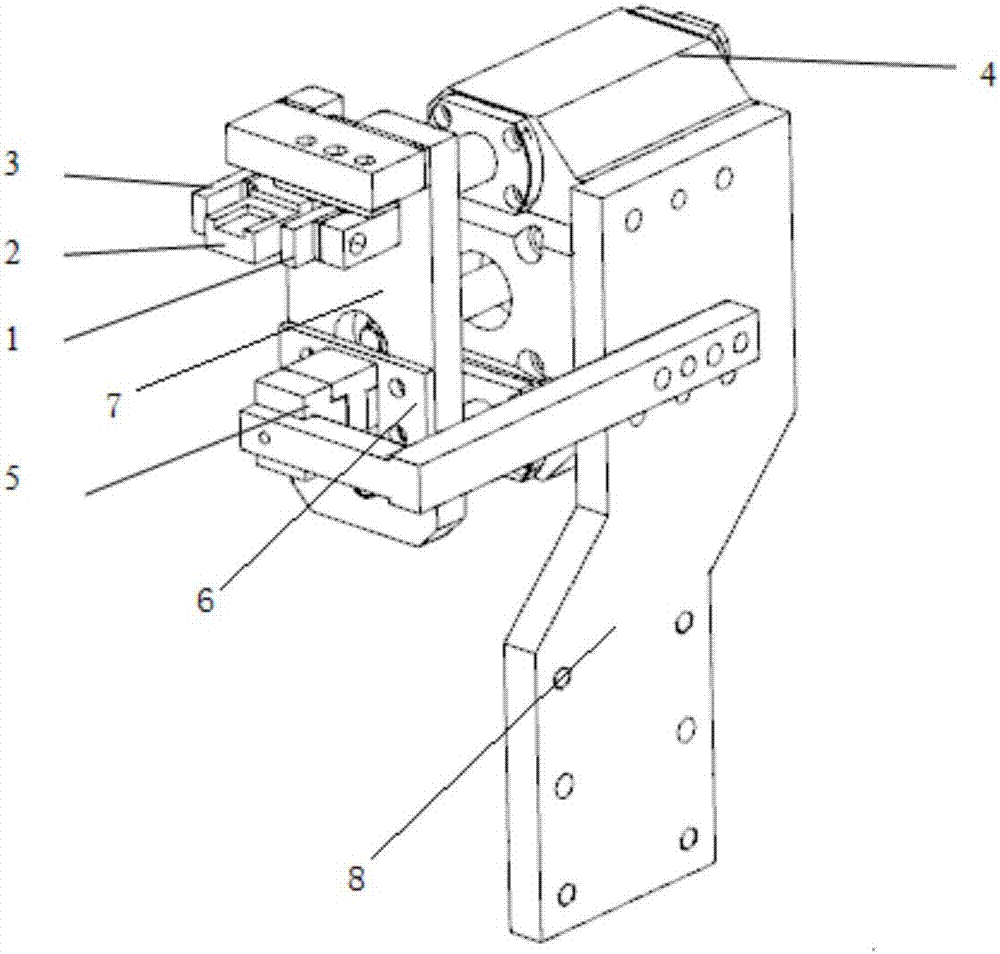

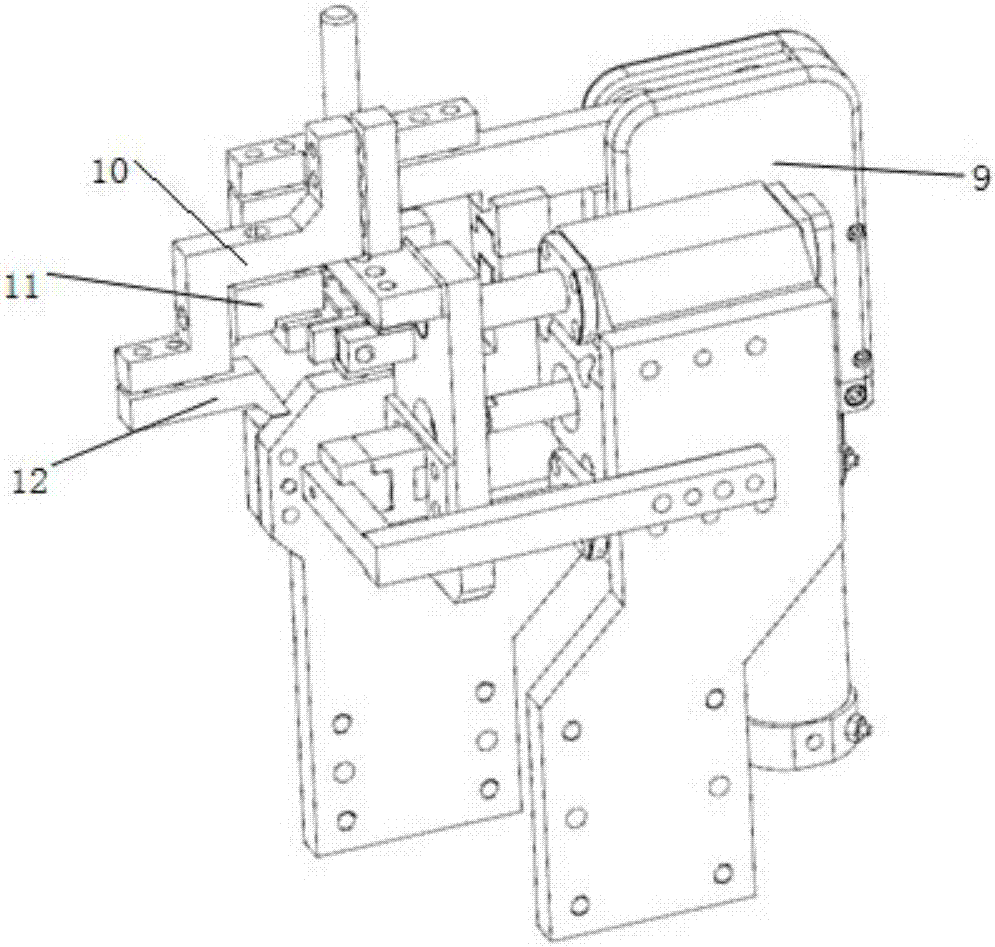

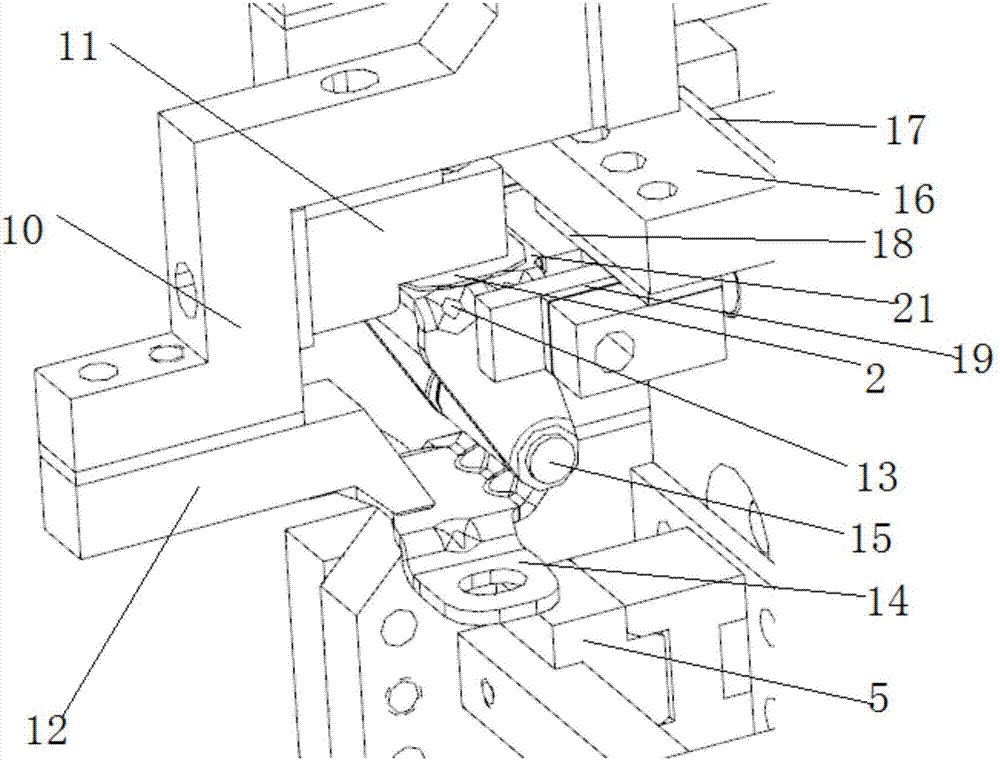

Mounting positioning device for automobile tail door hinge

PendingCN107081579AReduce positioning deviationPrecise positioningMetal working apparatusMechanical engineeringPiston

The invention provides a mounting positioning device for an automobile tail door hinge and belongs to the field of tool clamps used for automobile production. The mounting positioning device comprises a telescopic positioning mechanism and a turnover clamping mechanism. The telescopic positioning mechanism comprises a telescopic cylinder assembly, a hinge supporting block, side face limiting plates and a limiting block, wherein the hinge supporting block is connected with a piston head of the telescopic cylinder assembly and limits the position of the tail door hinge in the X direction, the side face limiting plates are arranged on the two sides of the hinge supporting block and used for limiting the position of the hinge in the Y direction, and the limiting block is arranged below the hinge supporting block and used for limiting the tail door hinge. The turnover clamping mechanism comprises a turnover cylinder assembly, a first pressing block and a second pressing block, wherein the first pressing block and the second pressing block are connected with the turnover cylinder assembly. The first pressing block can turn over and compress the hinge supporting block. The second pressing block can be matched with the limiting block to compress the tail door hinge. The mounting positioning device has the beneficial effects that a certain full control faces are utilized to achieve full positioning to position the hinge, and positioning deviation caused by imprecise positioning of a hinge screw is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

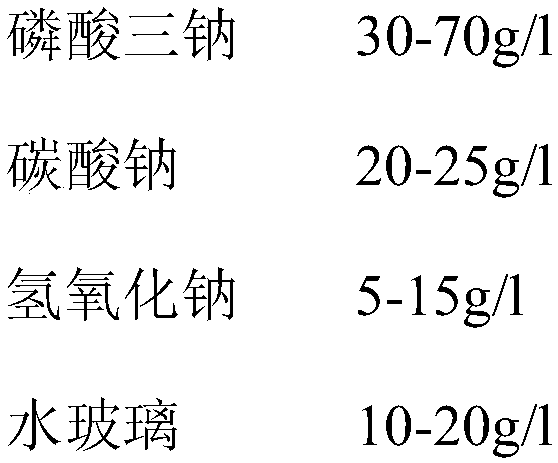

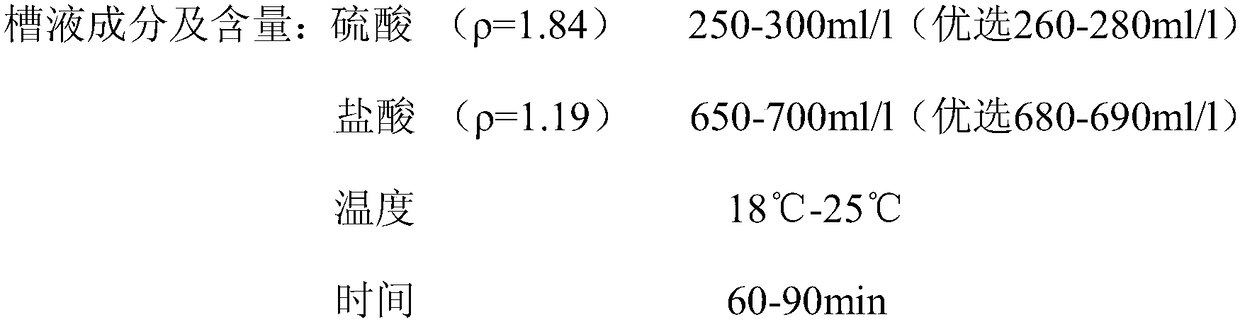

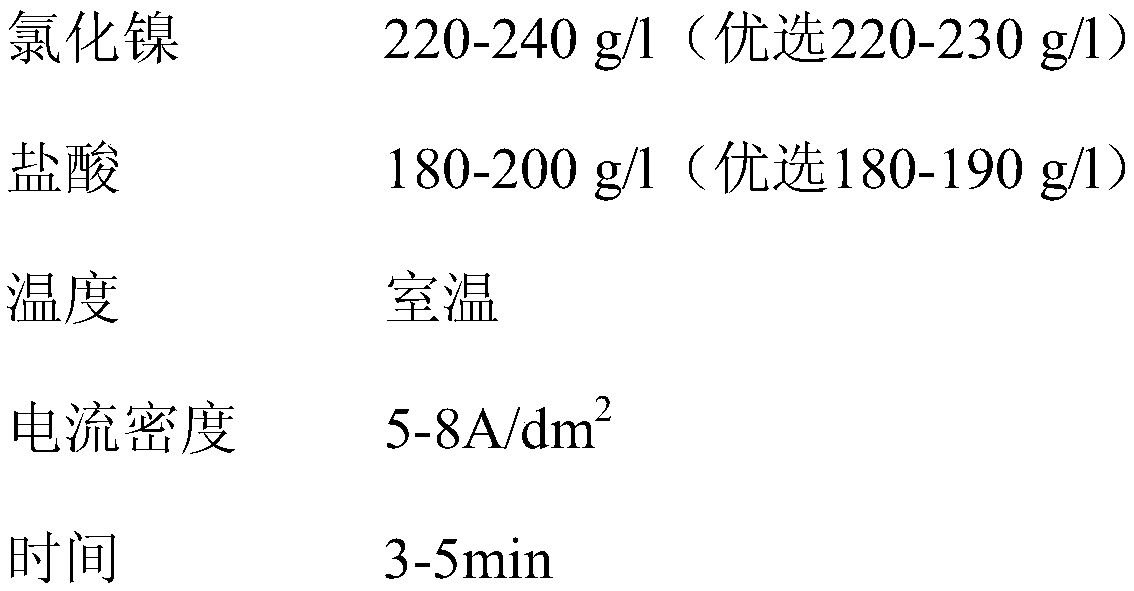

Local size repairing method for engine titanium alloy component

InactiveCN108103484AIncreased microhardnessImprove wear resistanceLiquid/solution decomposition chemical coatingSocial benefitsTitanium alloy

The invention aims at providing a local size repairing method for an engine titanium alloy component. The local size repairing method is characterized in that a chemical nickel plating method is adopted for size repairing; and the technology process is oil removal, non-plated surface protection, sand blowing, corroding, activating treatment, nickel preplating, chemical nickel plating and heat treatment. The method can solve the problems about component size out-of-tolerance and old clad layer repairing, the service life of components is prolonged, the engine producing and repairing requirements are met, the repairing cost is reduced, and obvious economic and social benefits are achieved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Machining method for self-adaptive milling of outer profile of split casing

ActiveCN110899782AGuarantee processing qualityImprove processing qualityAutomatic control devicesFeeding apparatusMilling cutterEconomic benefits

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

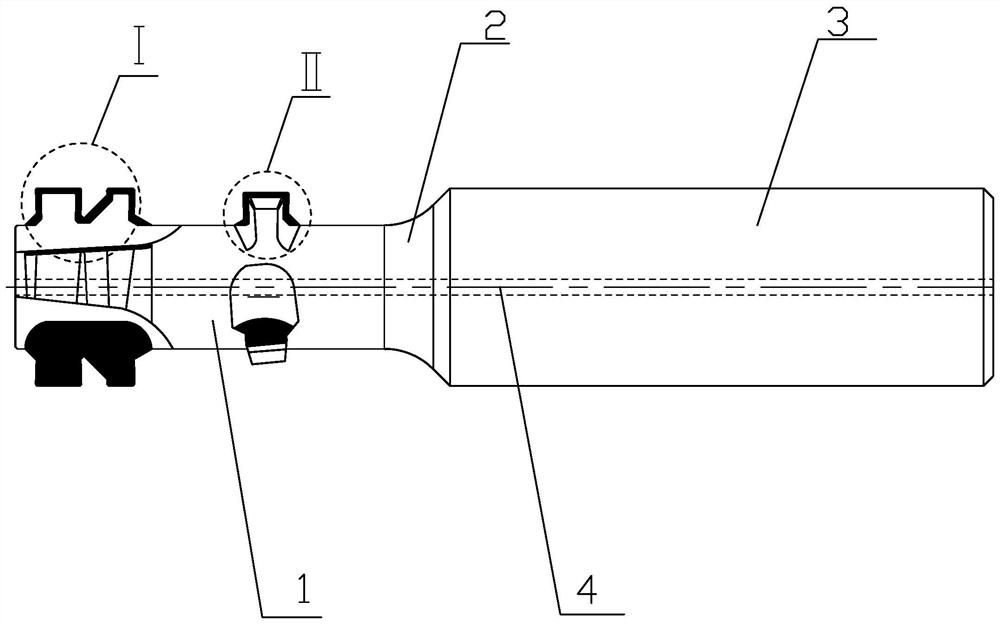

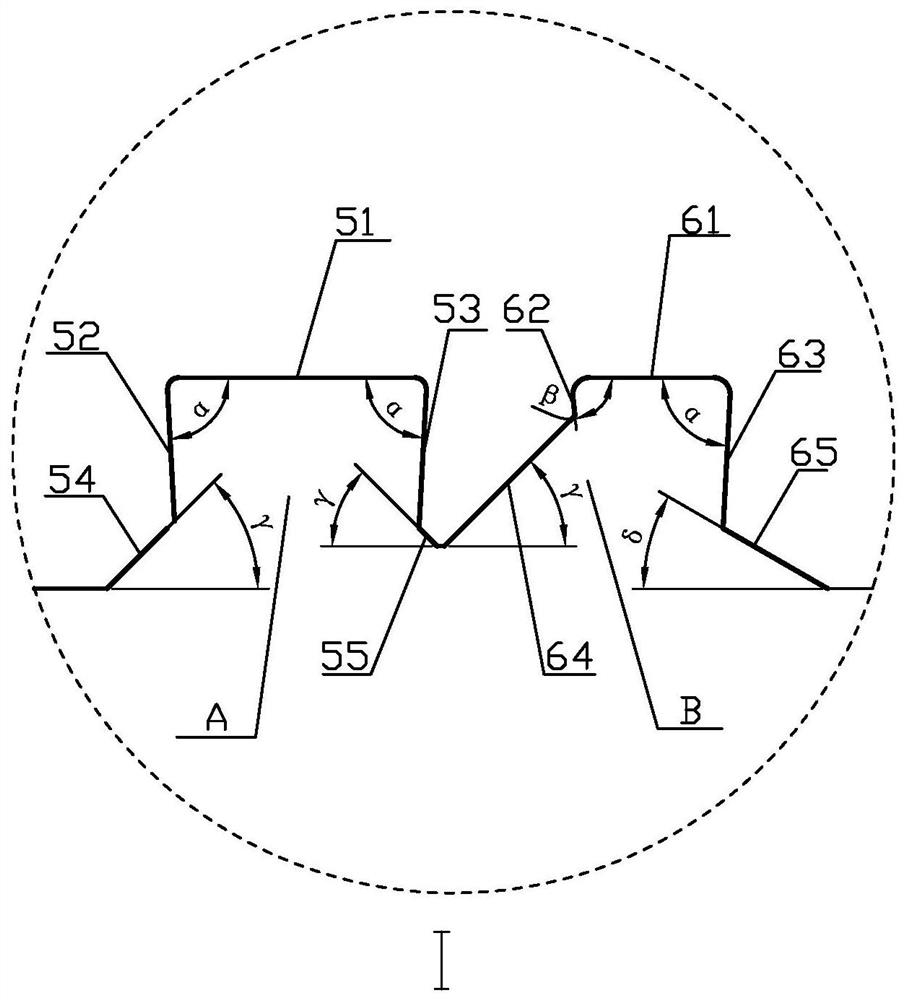

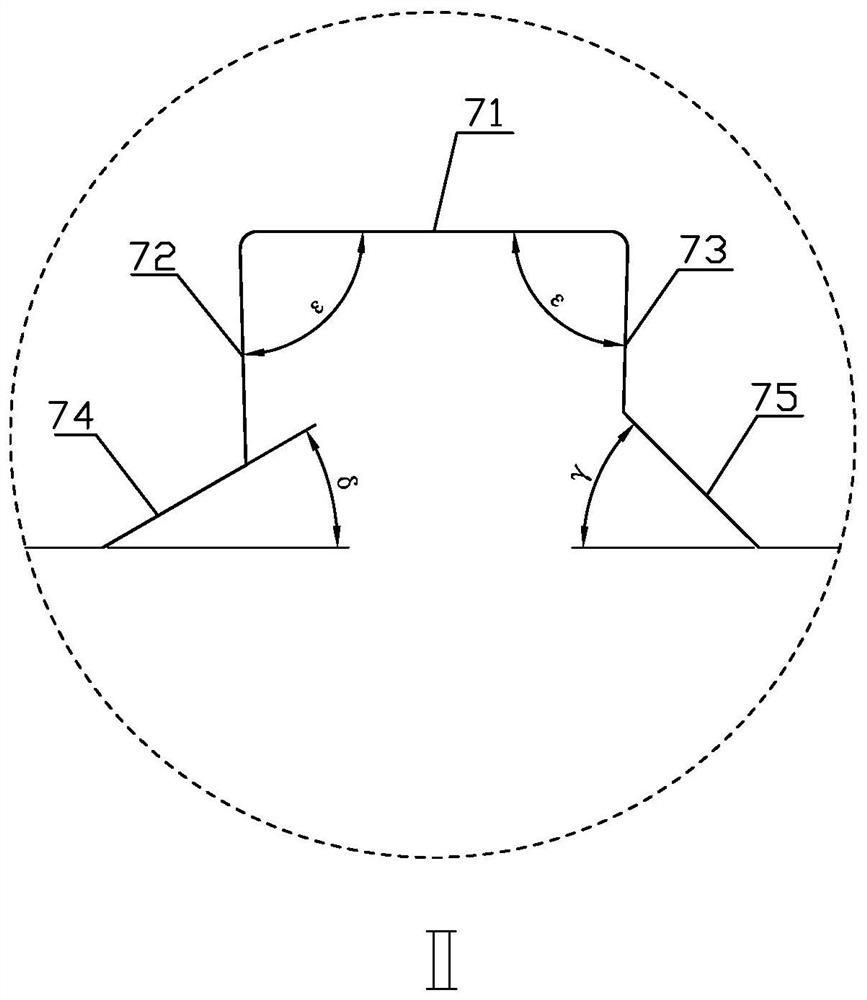

PCD forming milling cutter for machining automobile inlay

PendingCN112974923AEliminate repetitive positioning errorsPrecise deliveryTransportation and packagingWorkpiecesMilling cutterKnife blades

The invention discloses a PCD forming milling cutter for machining an automobile inlay. The PCD forming milling cutter for machining the automobile inlay is characterized in that the PCD forming milling cutter comprises a cutter handle and a cutter body, the joint between the cutter handle and the cutter body is in smooth curve transition, and a first cutting part and a second cutting part are sequentially arranged between the front end of the cutter body and the cutter handle; the first cutting part and the second cutting part are respectively composed of two or more blades distributed along the circumference of the cutter body, each blade in the first cutting part is composed of two continuous cutting edges, the blade of the second cutting part is provided with a cutting edge, the three cutting edges are respectively composed of an outer side cutting edge and an inner side buffering part, each blade is of a wedge-shaped structure with a wide outer side and a narrow inner side, and outer edge angles formed by the blades and the side faces of the blades are all provided with round chamfers. The PCD forming milling cutter for machining the automobile inlay can be used for machining automobile inlay parts, and the machined embedded parts are tightly embedded and are not prone to loosening.

Owner:常州冶戈工具有限公司

A device capable of diagnosing a failure of a visibility sensor and a detection method

ActiveCN106646678BSimple structureReduce volumeMaterial analysis by optical meansMeasuring instrumentEngineering

Owner:ZHONGHUAN TIG TIANJIN METEOROLOGICAL INSTR

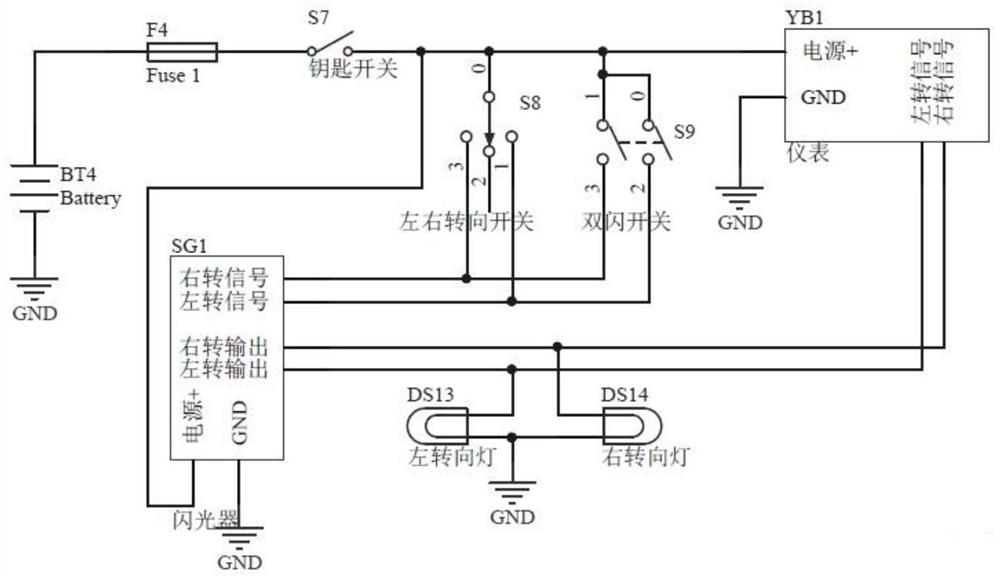

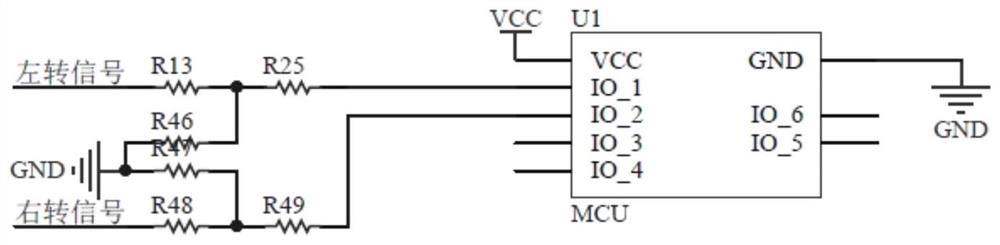

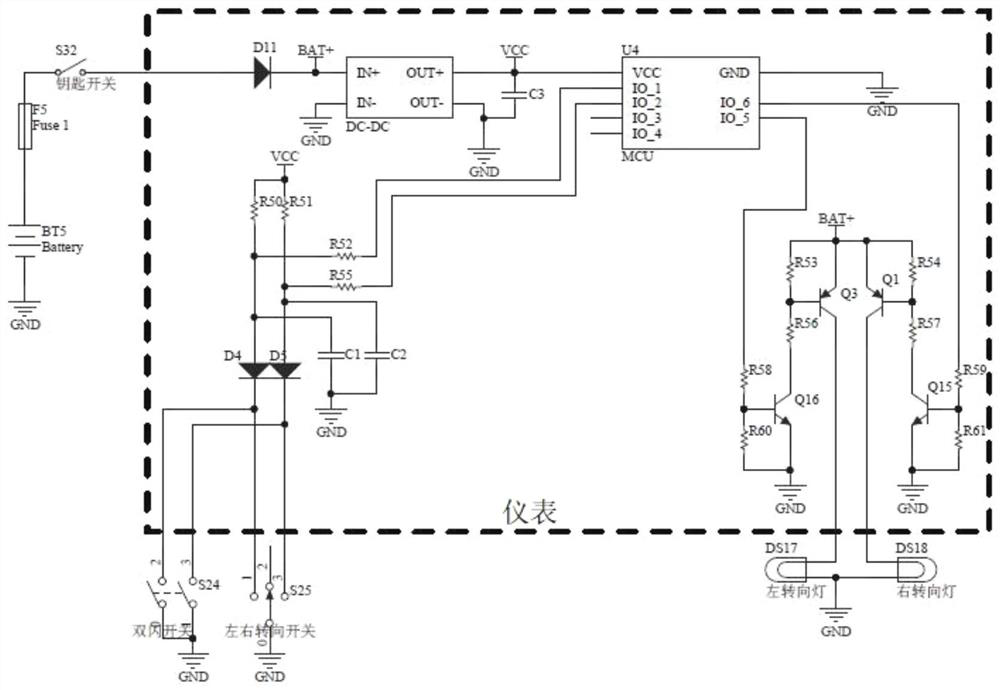

Switch waterproof circuit system for electric vehicle

PendingCN113696834AAchieve unified controlReduce complexityOptical signallingElectric/fluid circuitEngineeringStructural engineering

The invention provides a switch waterproof circuit system for an electric vehicle. An MCU module, a signal processing module and a driving module are configured on an instrument circuit board, the signal input end of the signal processing module is connected with a switch assembly, and the signal output end of the signal processing module is connected with the MCU module; the input end of the driving module is connected with the MCU module, and the output end of the driving module is connected with the steering lamp assembly. According to the switch waterproof circuit system for the electric vehicle, the signal processing module and the driving module are integrated on the instrument circuit board, a switch key signal is recognized through the MCU module to achieve the waterproof function and the signal acquisition function of a key, and meanwhile the driving circuit is controlled to achieve the flickering lightening function of left and right steering indicator lamps.

Owner:TIANJIN YADI IND

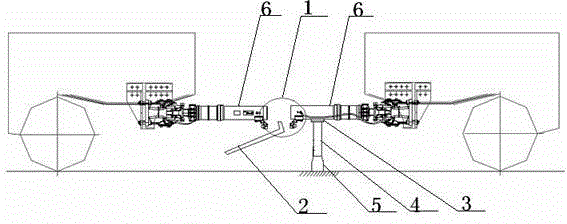

Car hook connecting and hanging method

The invention discloses a car hook connecting and hanging method. The method is characterized by comprising the following steps of: connecting dragging points among cars by using a hoisting belt at one side of a car body, and stirring and pulling the cars to a car hook connecting and hanging distance by using a stirring roller; matching by using a jack, a supporting rod and a cushion block and jacking up the car hooks after the car hook distance reaches the connecting and hanging distance, continuously stirring the hoisting belt by using the stirring roller, so that the connected and hanged car hooks are tightly connected without gaps; and mounting connecting rings after the car hooks are jacked up to a horizontal state and no gap exists between two car hooks. The car hook connecting and hanging method has the advantages of low manufacture cost, convenience in use and good on-site using effect, saves time and labor and is safe and reliable.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Low-solid ultra-high temperature water-based drilling fluid and preparation method thereof

ActiveCN108949127BReduce pollutionImprove suspension abilityDrilling compositionMetallurgyPhysical chemistry

The invention discloses a low-solid phase ultrahigh-temperature water-based drilling fluid which is prepared from the following components in parts by weight: 100 parts of solvent water, 3-4 parts ofbentonite, 1.8-2.2 parts of a coating inhibitor, 2.3-3.5 parts of a filtrate reducer, 2-2.5 parts of high-temperature resistant resin, 2-2.5 parts of a shale inhibitor, 1.5-2 parts of a stripping agent and 15-35 parts of ultrafine calcium carbonate. The preparation method is simple. The preparation method comprises the following steps: adding a certain amount of bentonite into the solvent water toprepare prehydrated bentonite slurry; then successively adding the coating inhibitor, the filtrate reducer, the high-temperature resistant resin, the shale inhibitor, the stripping agent and ultrafine calcium carbonate while performing high-speed electric stirring; and finally, carrying out hydration at room temperature for 24 hours to prepare the low-solid phase ultrahigh-temperature water-baseddrilling fluid. The low-solid phase ultrahigh-temperature water-based drilling fluid can resist a temperature high up to220 DEG C, the low-solid phase ultrahigh-temperature water-based drilling fluidis good in rheological property, rock carrying property and high in blocking inhibiting property, the problem of low density carrying stability is solved, the low-solid phase ultrahigh-temperature water-based drilling fluid is successfully applied in mounting and probing a 4X well, and a good field application effect is obtained.

Owner:CNPC BOHAI DRILLING ENG +1

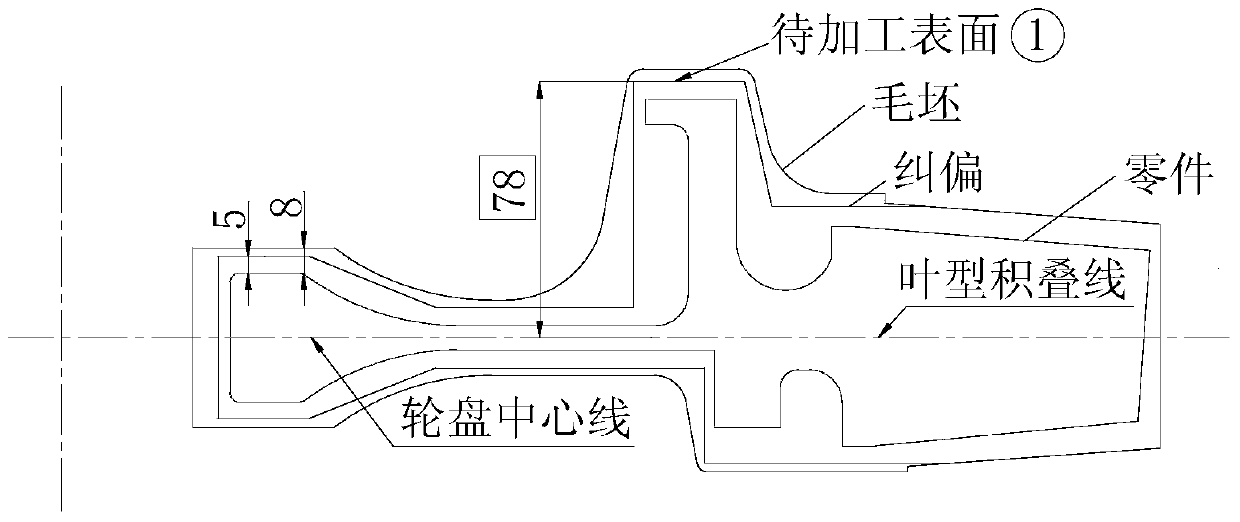

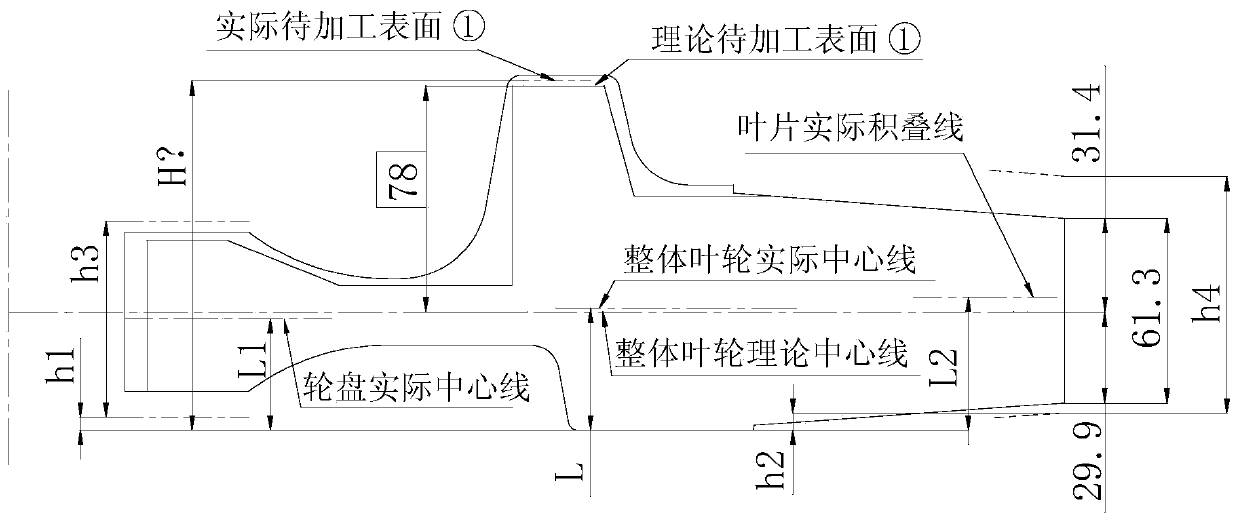

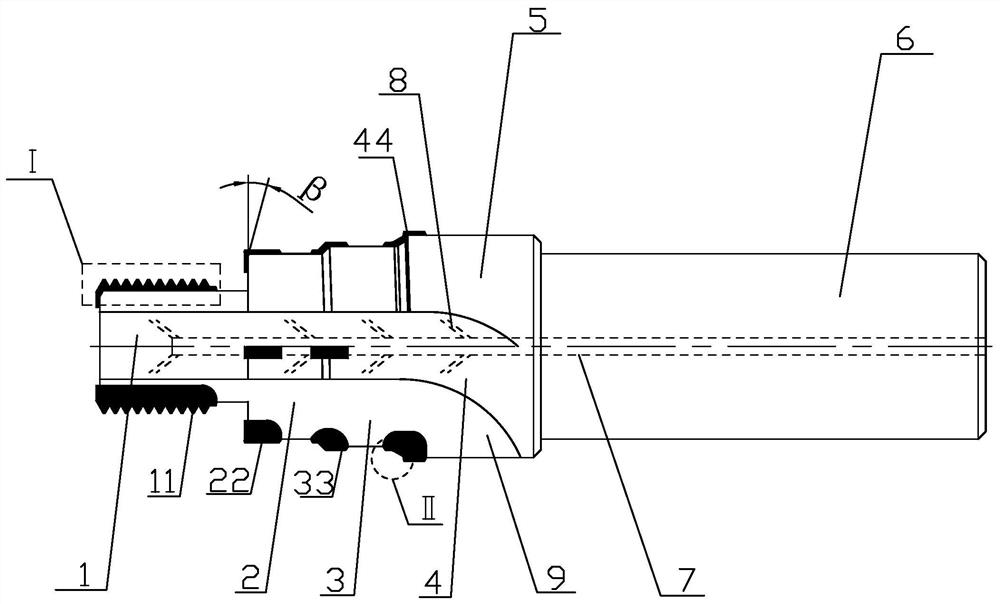

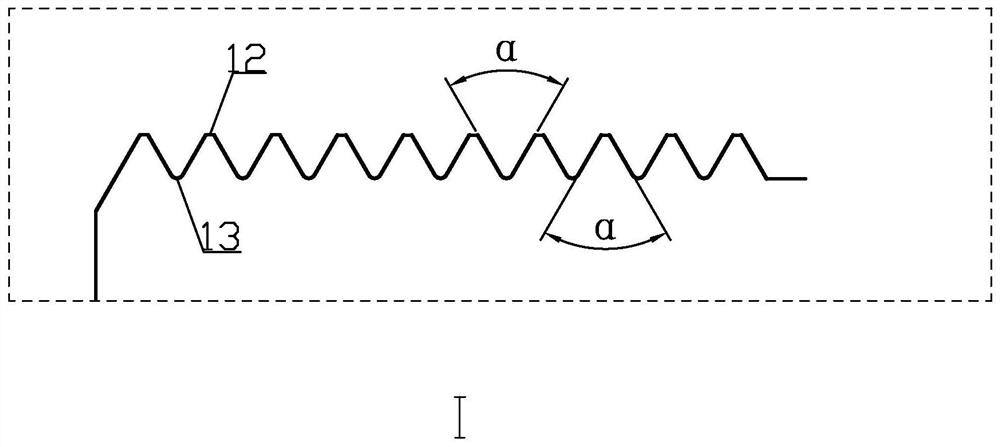

A Calculation Method of Correction of Center of Integral Impeller

InactiveCN103593499BAvoid the possibility of scrappingGood on-site useSpecial data processing applicationsImpellerEngineering

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

PCD combined cutter for machining automobile steering device

PendingCN113118572AEliminate repetitive positioning errorsPrecise deliveryThread cutting toolsWorkpiecesKnife bladesSerration

The invention discloses a PCD combined cutter for machining an automobile steering device. The PCD combined cutter comprises a cutter body and a cutter handle. The cutter body is arranged at the left end of the cutter handle, four cutting parts are arranged on the cutter body in sequence from the left end to the right end, the four cutting parts are connected in a stepped mode and are cylinders, the diameters of the four cutting parts are sequentially increased, and two or more cutting blades are arranged on each cutting part along the circumferential ring. The first cutting part is arranged at the front end of the cutter body, the first blades extend from the left end face of the first cutting part to the rear half section of the first cutting part, and the shapes of the first blades are same and continuous waveform sawteeth. The second blades in the second cutting part are arranged at the outer edge corner of the left end face of the second cutting part, and the second cutting part and the third cutting part are connected through an inclined plane. The third blades extend from the rear end of the second cutting part to the front end of the third cutting part. The fourth blades are arranged at the joint of the third cutting part and the fourth cutting part, the joint is formed by two inclined planes with different angles, the fourth blades extend from the rear end of the third cutting part to the front end of the fourth cutting part, and the shapes of the fourth blades are consistent with the shape of the joint.

Owner:常州冶戈工具有限公司

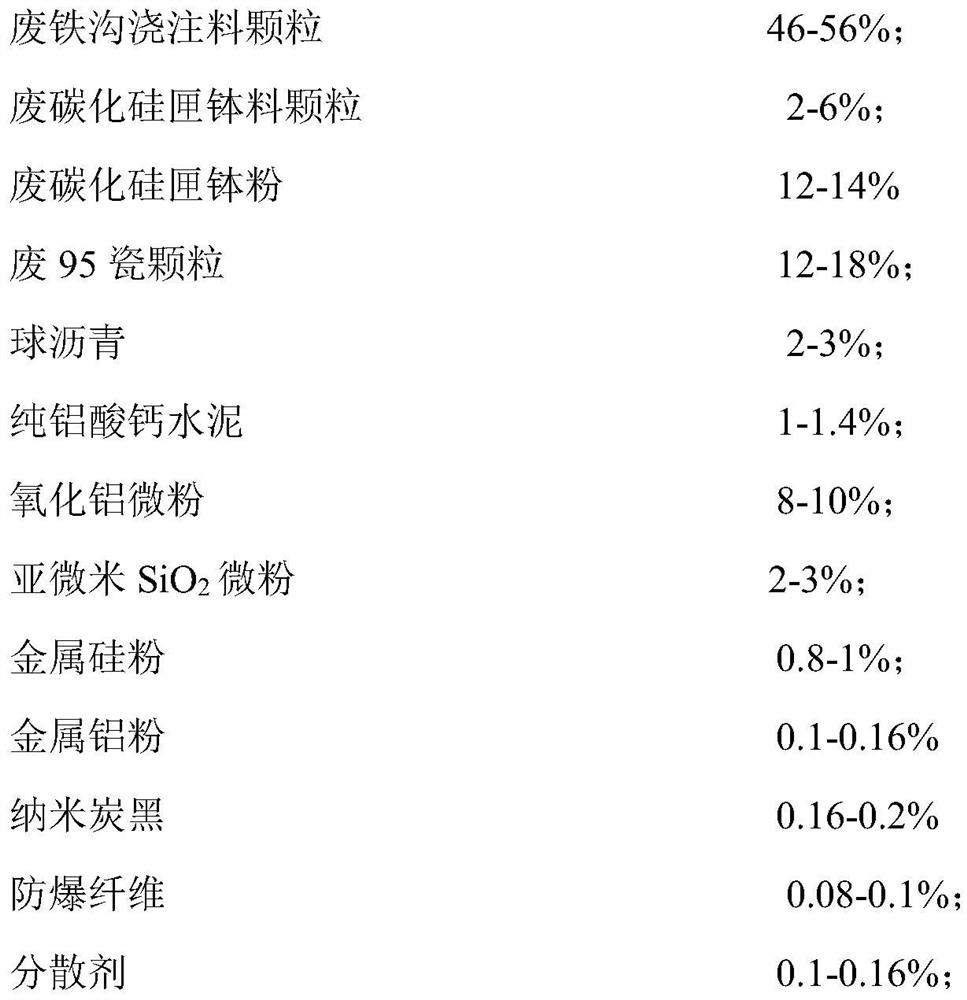

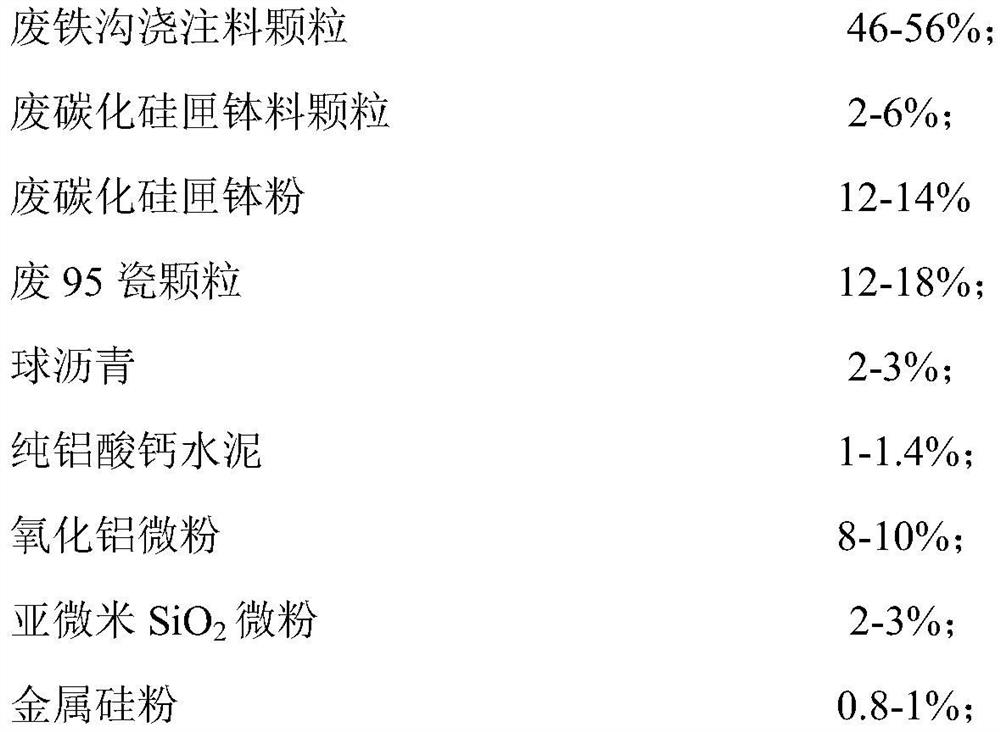

Novel iron runner castable with waste refractory as main material

ActiveCN113526967ASolve the problem of high temperature performance degradationBreak through the water limitAl powderFiber

The invention provides a novel iron runner castable with a waste refractory as a main material. The novel iron runner castable comprises the following components in percentage by mass: 46-56% of waste iron runner castable particles; 2-6% of waste silicon carbide sagger material particles; 12-14% of waste silicon carbide sagger powder; 12-18% of waste 95 ceramic particles; 2-3% of ball pitch; 1-1.4% of pure calcium aluminate cement; 8-10% of alumina micro powder; 2-3% of submicron SiO2 micro powder; 0.8-1% of metal silicon powder; 0.1%-0.16% of metal aluminum powder; 0.16- 0.2% of nano carbon black; 0.08-0.1% of explosion-proof fiber; and 0.1%-0.16% of a dispersing agent; and the iron runner castable is formed by uniformly stirring the above components and 5% of water by performing vibration molding. According to the iron runner castable, various waste materials are fully utilized, so that the comprehensive cost of the iron runner castable is greatly reduced; and meanwhile, industrial application proves that the iron runner castable disclosed by the invention is good in field use effect, high in batch production operability, excellent in physical property and good in quality stability, and is suitable for each part of a casting house.

Owner:中冶武汉冶金建筑研究院有限公司 +1

Machining method for offset milling of conical outer surface of casing

ActiveCN105290473AImproved tool cutting angleIncreased flank cutting rangeMilling equipment detailsG-codeFeed point

The invention relates to a machining method for offset milling of the conical outer surface of a casing. The method comprises the following steps that UG software is used for compiling milling operation of the conical outer surface of the casing; the milling sequence and the tool path of the conical outer surface of the casing are planned; a special post processing program of the UG software is customized; the special post processing program is used for creating a G code program recognized by a machine tool; the milling sequence and the tool path of the conical outer surface of the casing are planned as follows: the conical outer surface of the casing is divided into multiple curved face areas, each curved face area serves as an independent drive body, each curved face area is shown with (U,V) parameters, the feed point selects the middle position of each curved face area, and the included angle theta between the feed direction and the cutting direction is greater than 90 degrees but smaller than 270 degrees. The cutting angle of a tool is improved, the cutting range of a side edge is enlarged, cutting of a bottom edge is reduced, and therefore abrasion of the tool is reduced, the machining efficiency is improved, and the numerical control milling problem of the conical outer surface of the casting is successfully solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com