Patents

Literature

40results about How to "Good anti-wax effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wax-resisting scale inhibitor for well

The present invention relates to belongs to the field of oil well wax-eliminating and scale inhibiting technology and provides one kind of solid wax-resisting scale inhibitor. Based on the wax solidifying and scaling law in oil well, some chemicals are selected and combined with some polymers with slow releasing function to produce into the solid wax-resisting scale inhibitor. The solid wax-resisting scale inhibitor is attached to bottom of oil pump and will be dissolved slowly by the flushing oil flow in well, and the dissolved wax-resisting scale inhibitor acts on the inside of oil pipe and oil pump to inhibit wax molecule aggregation and scaling, with the wax and scale being maintained in dispersed state and pumped to ground together with oil flow.

Owner:DAQING OILFIELD CO LTD

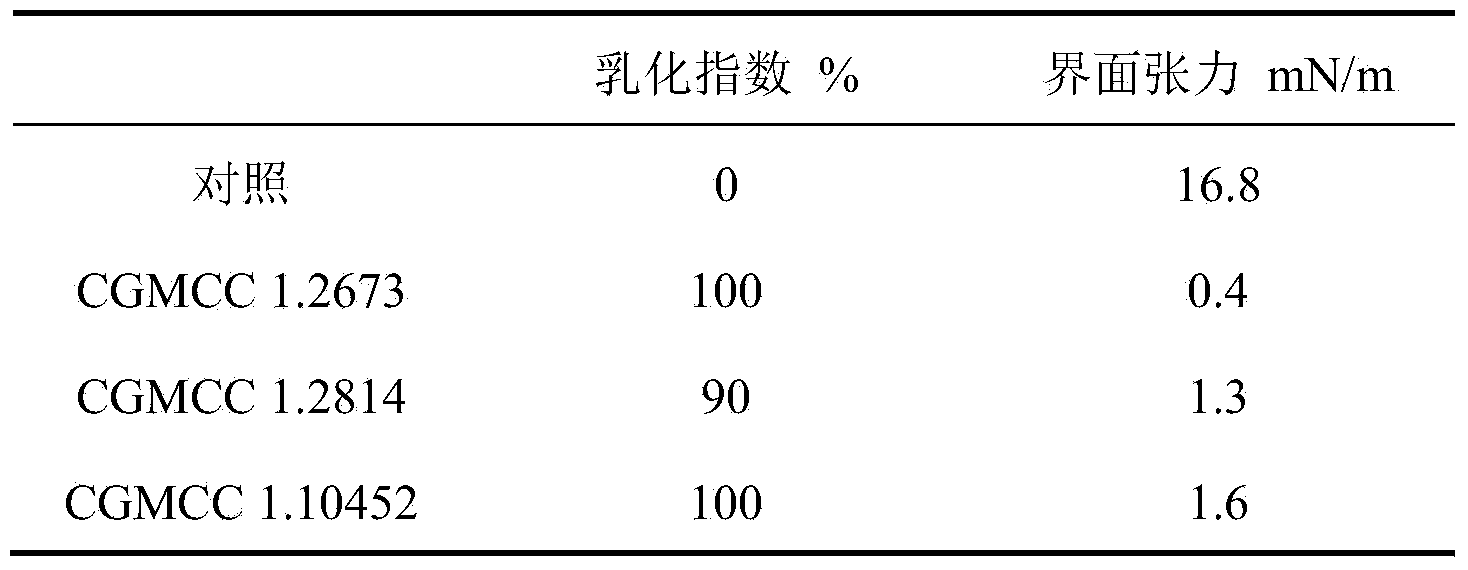

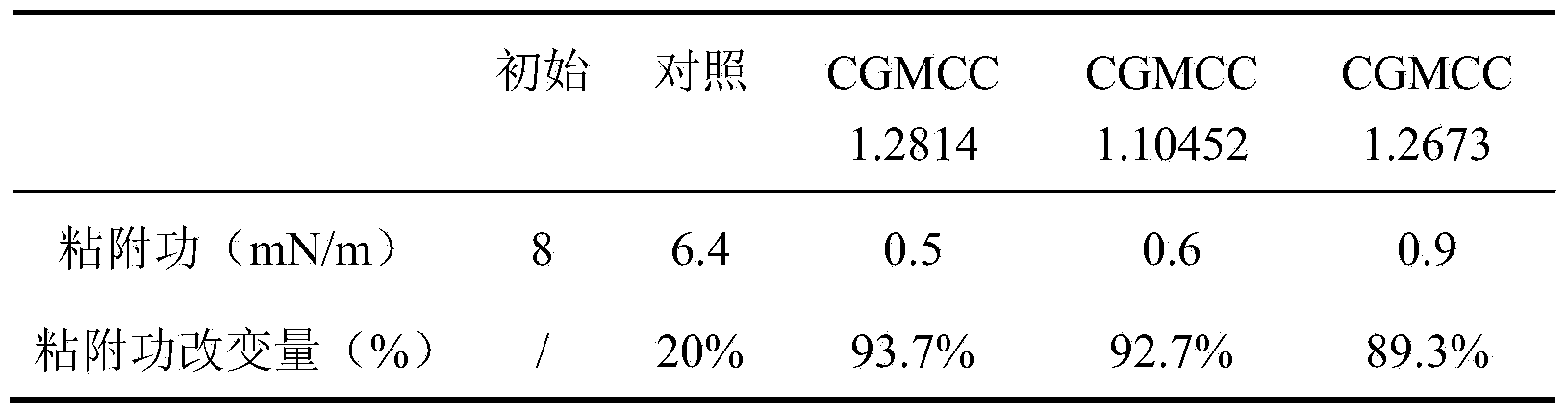

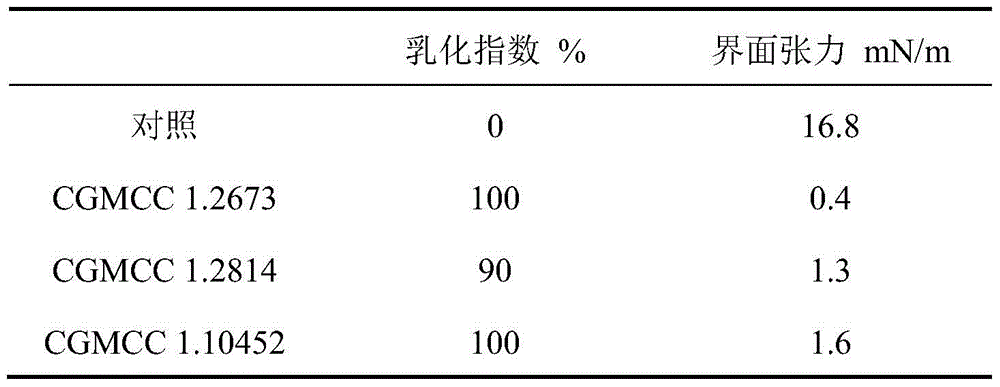

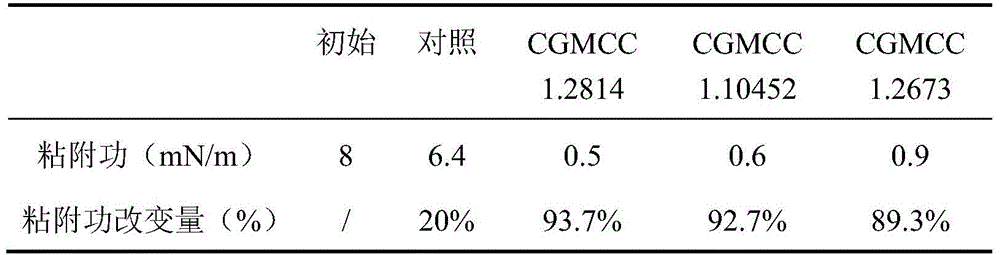

Strong emulsibility microbe wax cleaning and preventing bacterial agent and application thereof

ActiveCN104109516AStrong emulsifying abilityReduce interfacial tensionCleaning apparatusFluid removalInhibition zoneOil production

The invention discloses a strong emulsibility microbe wax cleaning and preventing bacterial agent and an application, which belongs to the oil field chemical technology field. The wax cleaning and preventing bacterial agent mainly comprises pseudomonas aeruginosa and geobacillus sp, has strong emulsification capability, and is capable of dispersing crude oil, promoting crude oil to flow, changing adherence force of borehole wall, preventing the accumulation of wax crystal on the borehole wall, and playing the paraffin inhibition and wax cleaning effects. By increasing the initial application amount of the bacteria liquid and prolong the well closing time, a stable paraffin inhibition zone can be formed due to adhesion of bacteria on borehole wall, near wellbore formation can be cleaned, and the paraffin inhibition and oil increase effects can be increased. After on-site enforcement, the well cleaning and chemical paraffin inhibition works can not be carried out in recent half year in the test wells, so that the wax cleaning and preventing bacterial agent has good paraffin inhibition effect in the well. The oil production is increased by about 30% daily, pump efficiency is increased about 10%, the surface tension of the output liquid is decreased to 20-25%, and the crude oil condensation point is decreased by 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

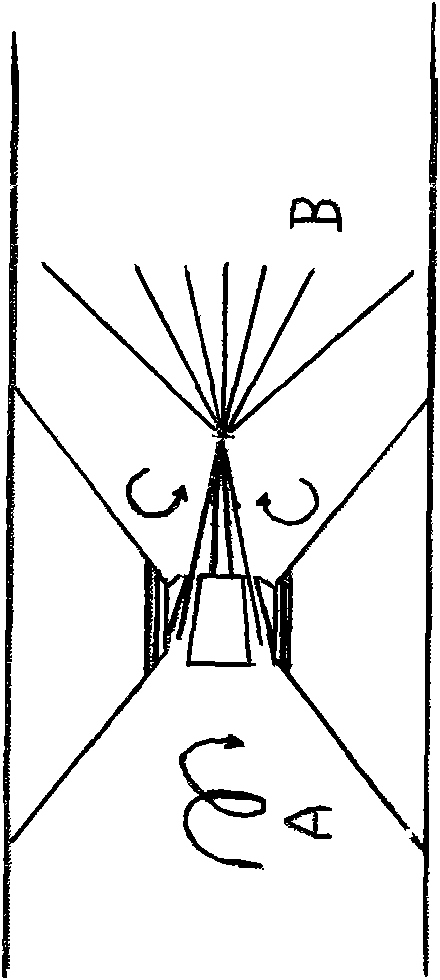

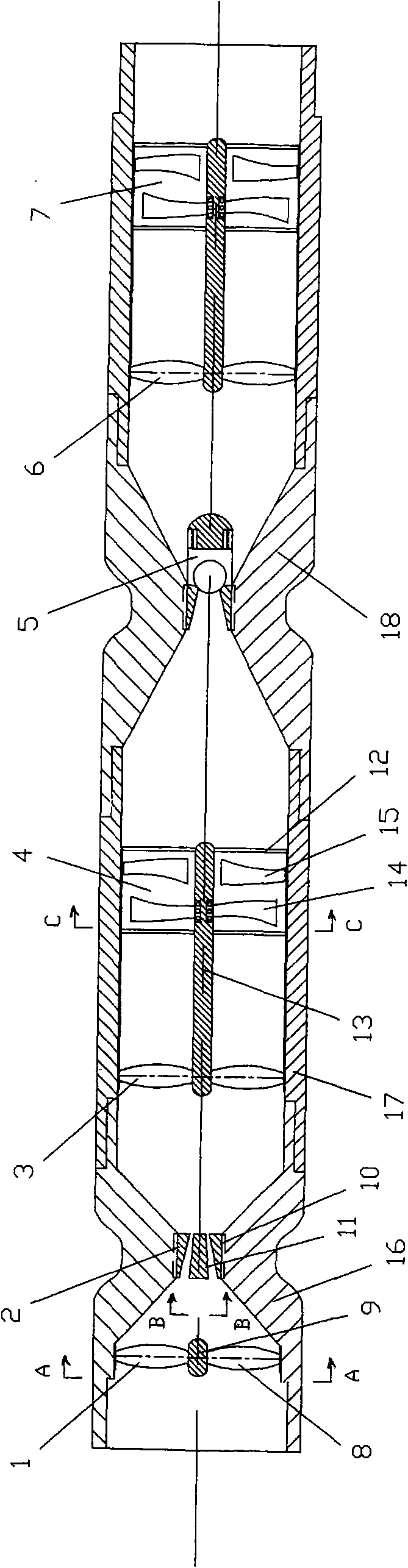

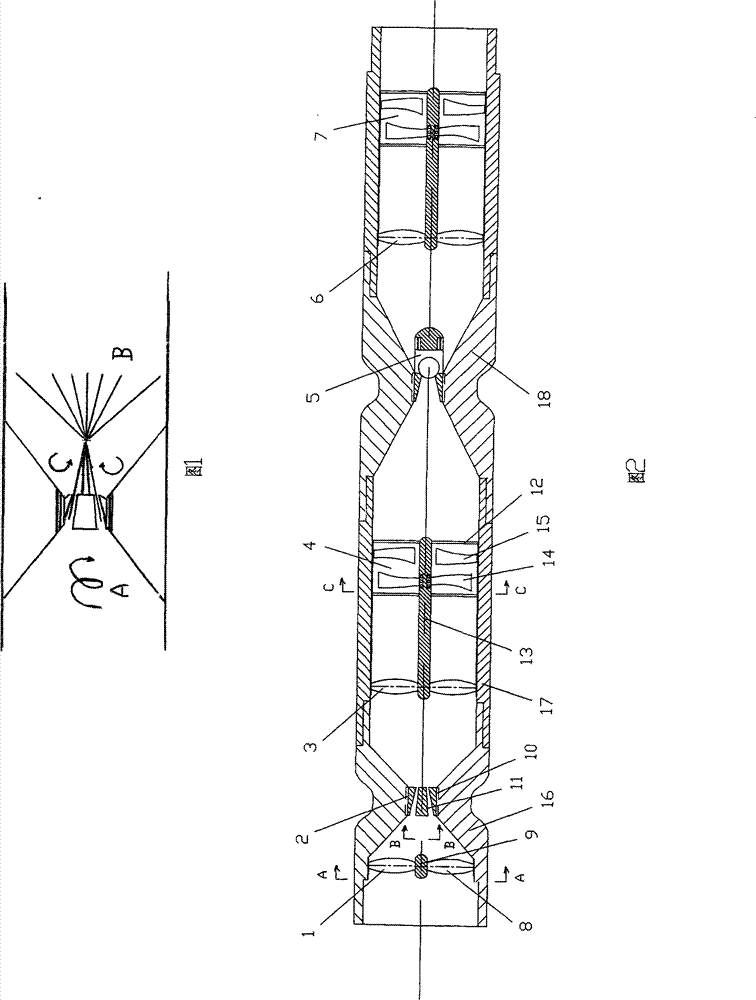

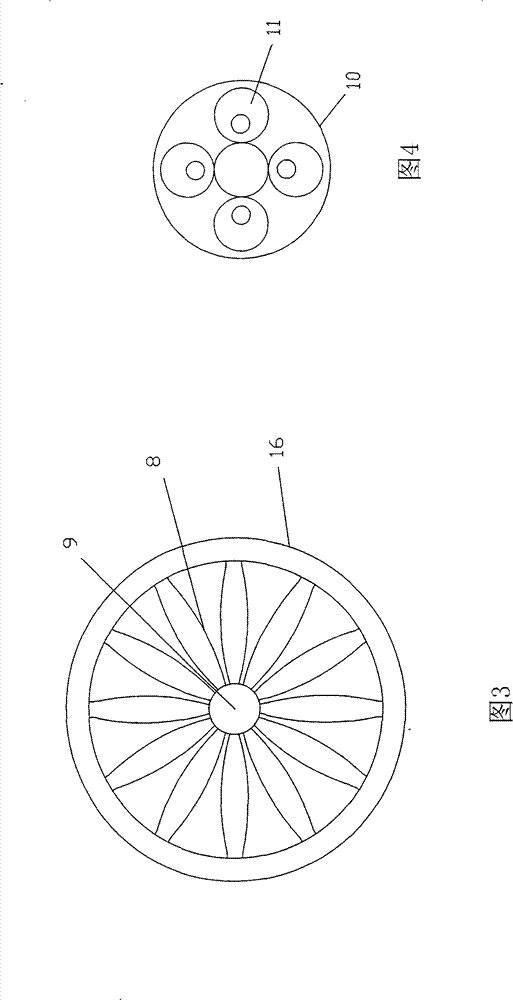

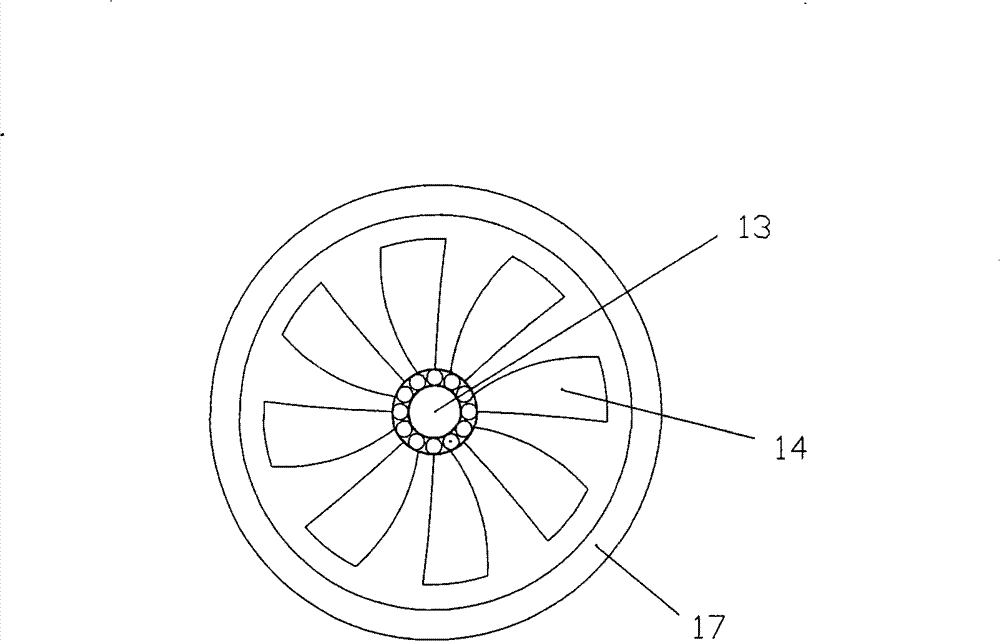

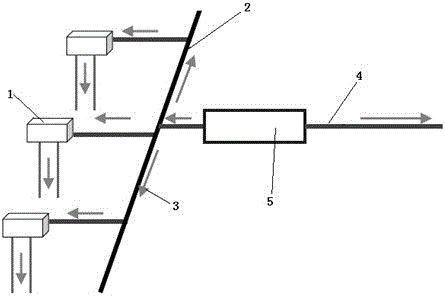

Multifunctional processor for liquid generated underground

InactiveCN101560876AGood anti-wax effectShaking/oscillating/vibrating mixersMixing methodsEngineeringCheck valve

The invention relates to petroleum extraction equipment which is a multifunctional processor for liquid generated underground. The processor is provided with a pipe barrel, and the tail end of the pipe barrel is provided with a check valve. The processor is characterized in that the pipe barrel is internally provided with a first-order grid type sound generator, an impinging nozzle atomizer, a second-order grid type sound generator and a first-order turbine mixed-phase device sequentially. The processor overcomes the defects that the prior products of the same class adopt magnets to prevent waxes and reduce the viscosity so as to be easy for adsorbing ferromagnetic substances to block wells; and a single-plate plate spring sound generator has small oscillation amplitude and sound intensity and quick weakening so as to influence the effects of preventing the waxes and reducing the viscosity. The processor has the ultrastrong functions of preventing the waxes and reducing the viscosity, improves the liquidity of crude oil and the pump effectiveness, has safety and environmental protection, and not only conforms to different types of the oil extraction wells, but also is suitable for the oil wells of different wax contents and water contents.

Owner:邓海波

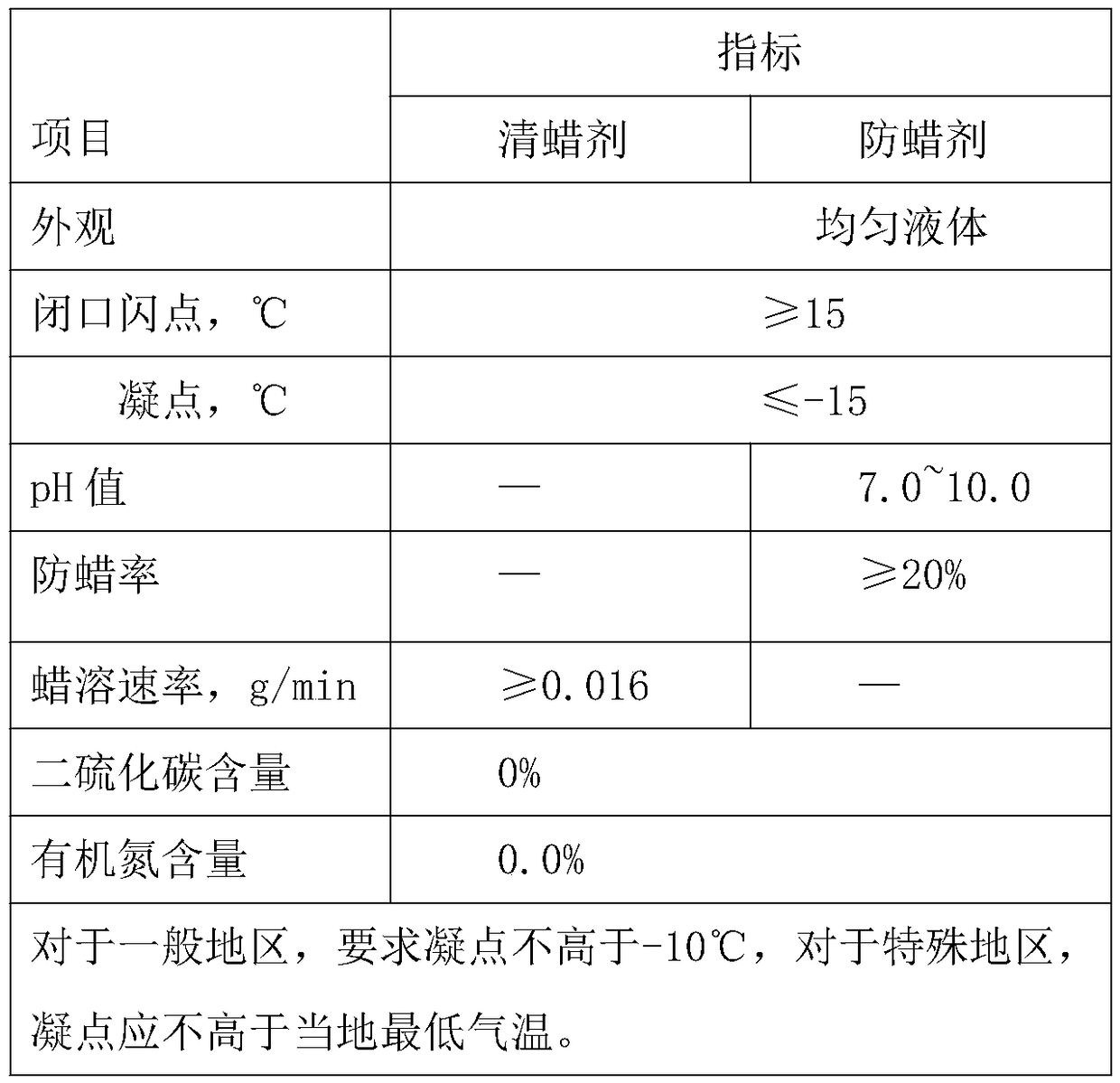

Anti-waxing agent special for heavy crude well thermal recovery

The invention relates to a special wax-proof agent for the thermal recovery of a heavy oil well which belongs to the technical field of oil field chemical product. The technical scheme thereof consists of the materials with the following weight portions: 20 to 30 portions of sherwood oil, 35 to 45 portions of dimethylbenzene, 5 to 10 portions of bottom oil, 3 to 5 portions of alkyl phenol polyoxyethylene ether, 2 to 5 portions of alkanolamides of fatty acid, 10 to 15 portions of fatty acid, 5 to 10 portions of alkaline liquid with a concentration of 25 to 35 as well as 100 to 150 portions of water. The special wax-proof agent has the advantages of high wax-dissolving speed, high viscidity reducing rate, good wax-proof effect, and the like. The efficiency and productivity for the thermal recovery of the heavy oil well can be greatly improved through adding wax-proof agent into the oil well periodically and being matched with a hot water thermal recovery technology; the construction is convenient.

Owner:赵芳

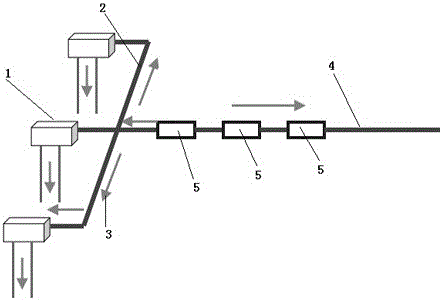

Permanent magnet ultrasonic paraffin control device

InactiveCN104863546AGood anti-wax effectImprove wax protectionCleaning apparatusElectricityParaffin oils

The invention relates to a permanent magnet ultrasonic paraffin control device. The permanent magnet ultrasonic paraffin control device is characterized by at least comprising an ultrasonic generator, a cable, an ultrasonic transducer, permanent magnets, magnet sleeves, a protection box, an inner pipe and two flange discs; the two ends of the inner pipe are provided with the two flange disc respectively, and the ultrasonic transducer is arranged on the inner wall of the inner pipe; the ultrasonic transducer is electrically connected with the ultrasonic generator located at the upper end of the outer wall of the inner pipe through the cable; the permanent magnets are arranged on the outer wall of the inner pipe and located at the lower end of the ultrasonic generator, and the magnet sleeves are arranged outside the permanent magnets; the portion, located between the two flange discs, of the inner pipe is sleeved with the protection box, and the ultrasonic transducer, the permanent magnets and the magnet sleeves are arranged in the protection box in a sleeved mode; the N poles and the S poles of the permanent magnets are arranged in a combined and alternating mode, so that a spiral strong alternating magnetic field is formed. Under the cooperative effect of the magnetic field and ultrasonic waves, the paraffin control effect is better.

Owner:山东鑫茂奥奈特复合固体润滑工程技术有限公司

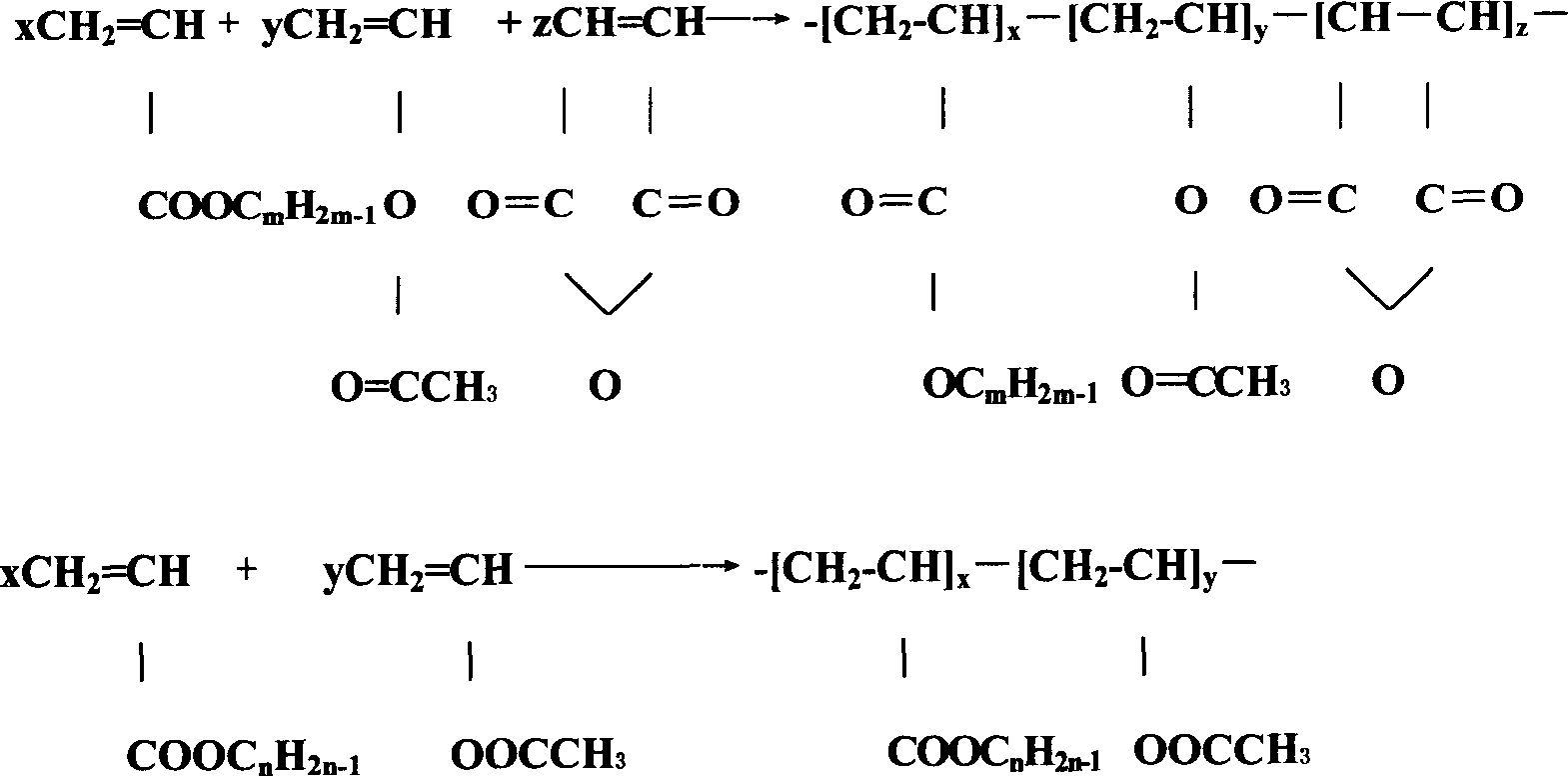

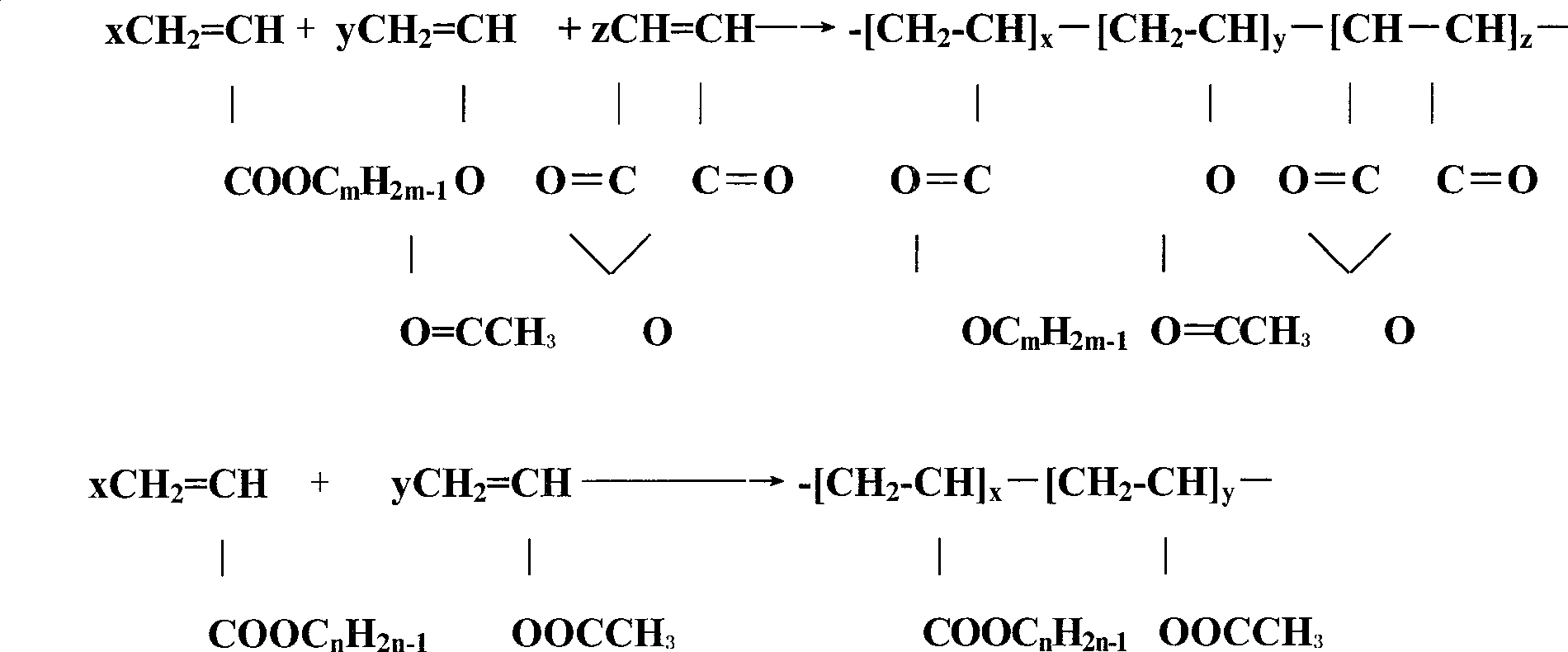

Special solid crude oil paraffin inhibitor for paraffin controller

ActiveCN107057669AOn-site construction is simpleLow costDrilling compositionCarvacryl acetateOleic Acid Triglyceride

The invention discloses a special solid crude oil paraffin inhibitor for a paraffin controller, and belongs to the technical field of crude oil paraffin inhibitor. The invention solves the technical problems that the existing crude oil paraffin inhibitor is stored in a wellbore, the period of regularly cleaning paraffin is short and the cost of regularly cleaning the paraffin is high. The solid crude oil paraffin inhibitor is prepared from an ionic fluorate type surfactant, an ionic citrate type surfactant, a nonionic citrate ester type surfactant, an organic montmorillonite and a quaternary copolymer by blending and injecting; the quaternary copolymer is prepared from monomeric acrylic acid high-carbon alcohol ester, vinyl acetate, oleic acid high-carbon alcohol ester and styrene by polymerizing. The paraffin inhibiting effect of the solid paraffin inhibitor matched with the paraffin controller is significant; the paraffin precipitation can be effectively inhibited in the process of oil recovery; the period of regularly cleaning the paraffin in the wellbore is greatly reduced; the oil recovery cost is reduced; the safe and stable operation of oil wells is ensured.

Owner:NORTHEAST GASOLINEEUM UNIV +1

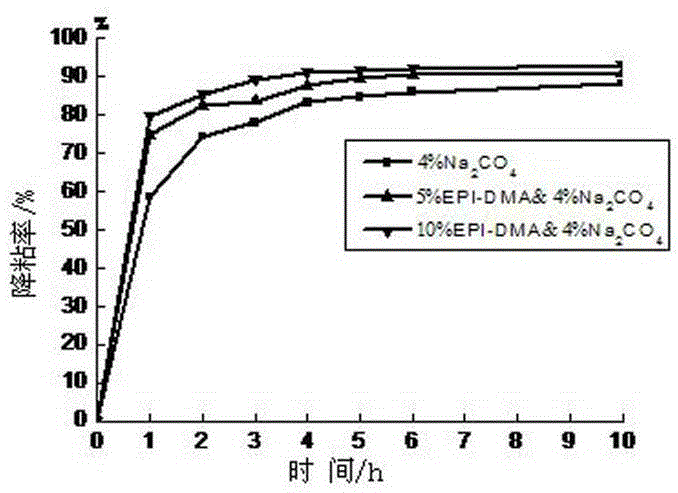

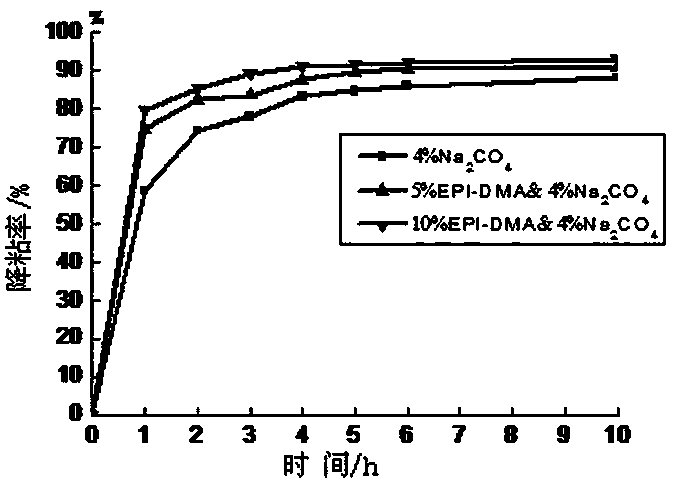

Method for relieving downward lag of polymer flooding production well sucker rod

ActiveCN105298458ASolve the problem of down lagLow degradation costCleaning apparatusFluid removalPhysical chemistryEnvironmental engineering

The invention relates to a method for relieving downward lag of a polymer flooding production well sucker rod. The method for relieving the downward lag of the polymer flooding production well sucker rod comprises the following steps: adding a polyamine flocculant, an oxidant, a corrosion inhibitor and an anti-scaling agent to a pumping well in normal production in a wellhead drip dosing manner, wherein the adding amount of the polyamine flocculant is 0.5%-0.8% of the mass of produced liquid of the pumping well, the adding amount of the oxidant is 0.3%-0.7% of mass of the produced liquid of the pumping well, the adding amount of the corrosion inhibitor is 0.1% of mass of the produced liquid of the pumping well, and the adding amount of the anti-scaling agent is 2%-4% of mass of the produced liquid of the pumping well; and forming an associated colloidal solution with ultra-low viscosity by the polyamine flocculant and polyacrylamide in the produced liquid, so that the produced liquid is easily mined from the ground. The associated colloidal solution with ultra-low viscosity is formed by the polyamine flocculant and the polyacrylamide in the produced liquid, so that the produced liquid is easily mined from the ground; the problem of the downward lag of a polymer flooding pumping unit is solved; and the degradation cost is low.

Owner:NORTHEAST GASOLINEEUM UNIV

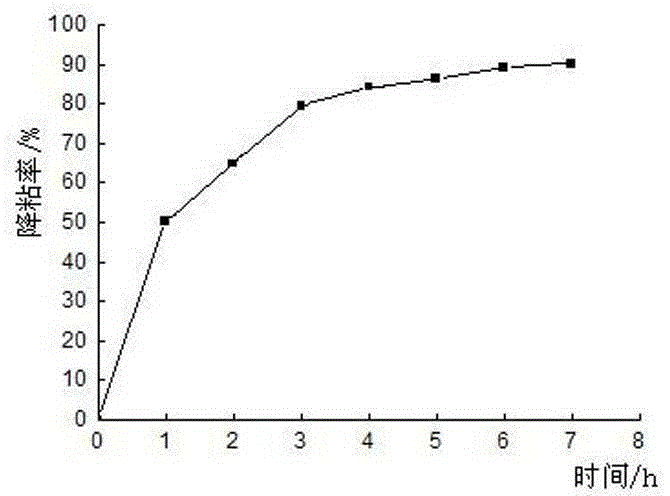

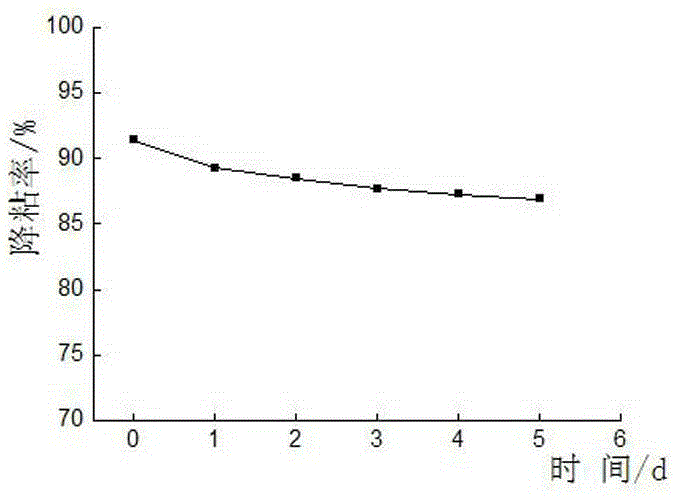

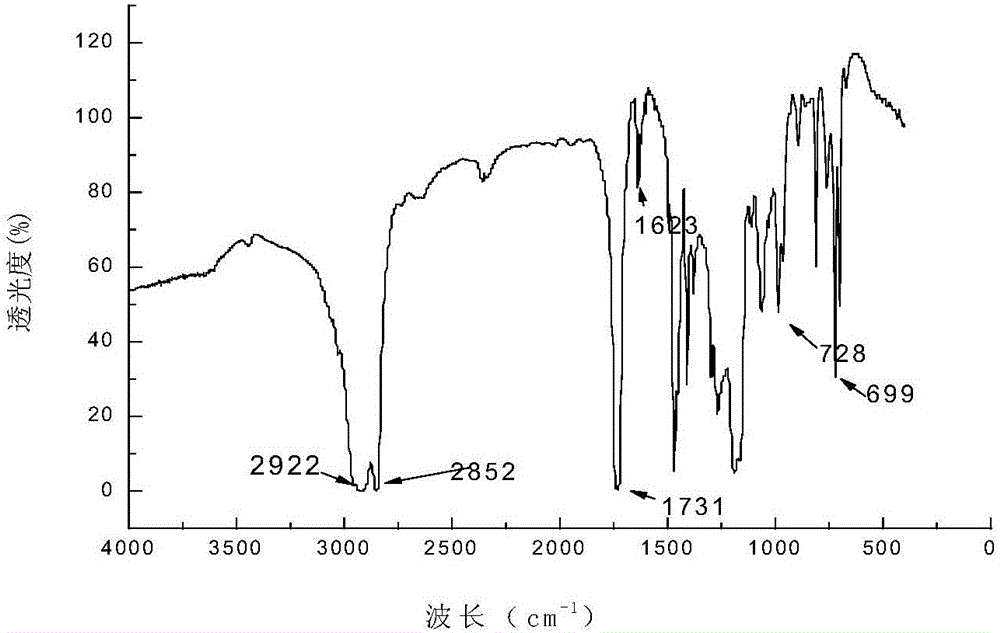

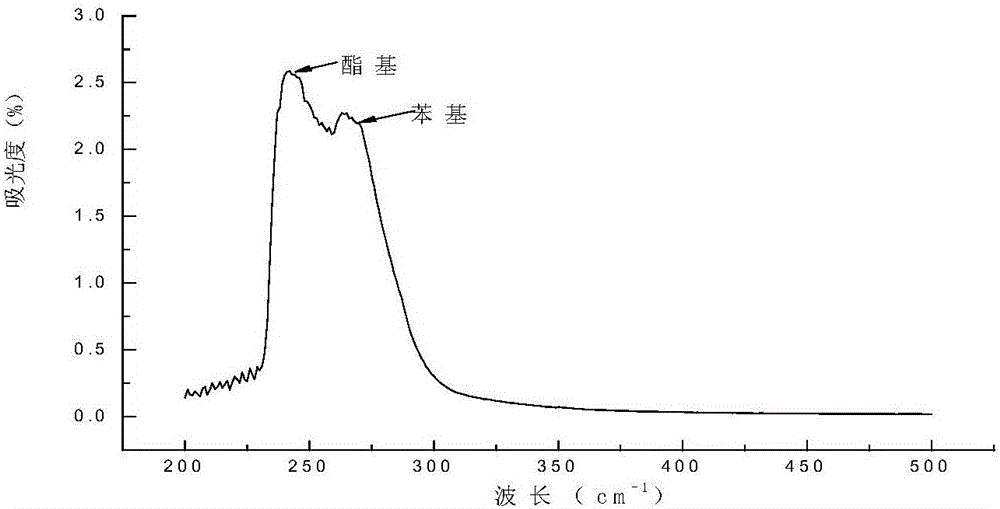

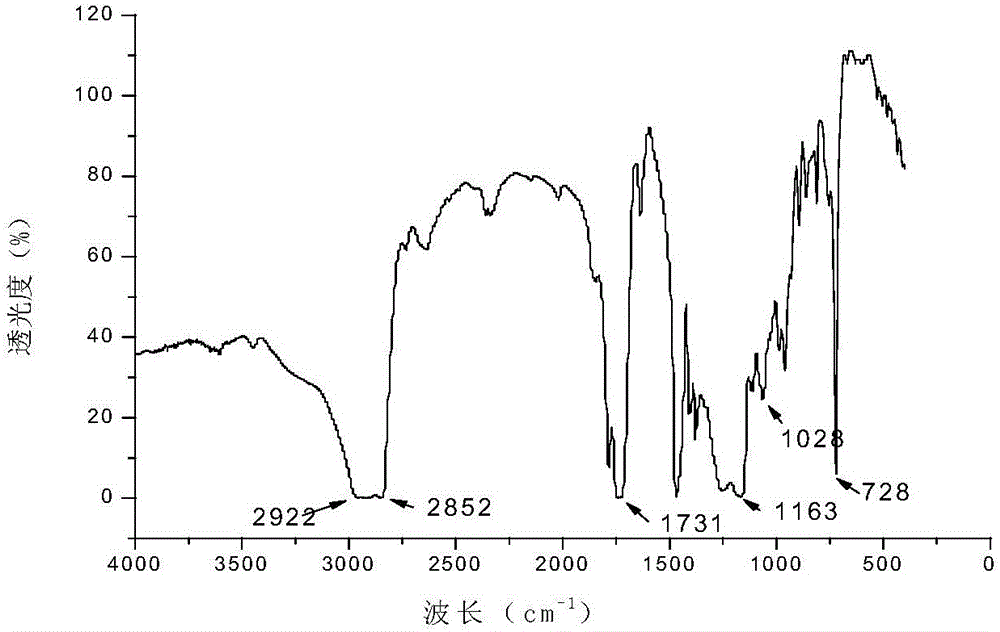

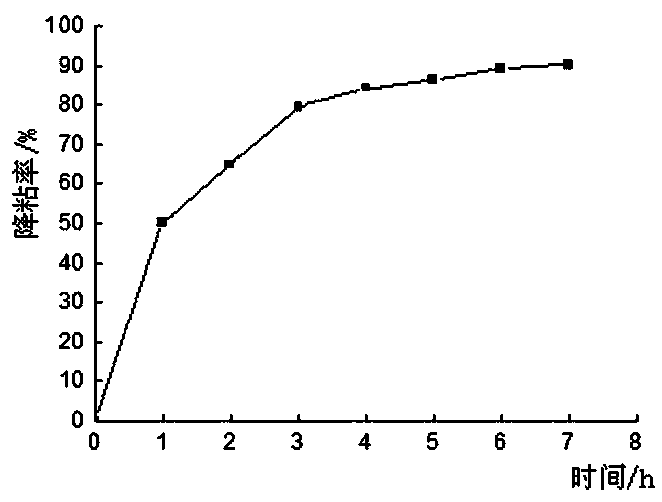

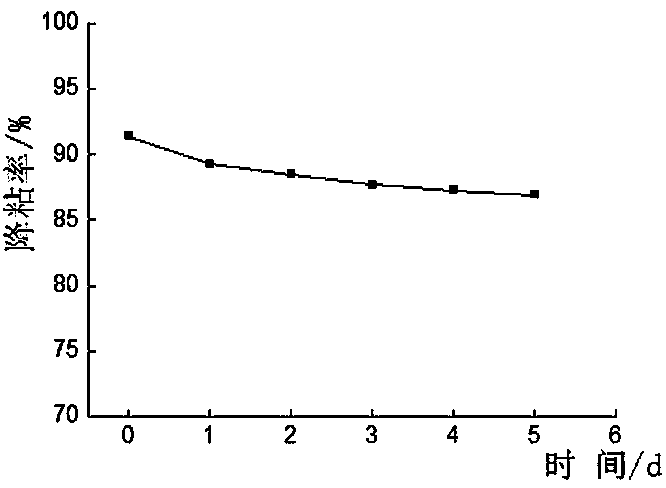

Paraffin inhibitor for petroleum extraction and preparation method thereof

InactiveCN104327815AGood anti-wax effectHigh wax resistanceDrilling compositionGlycerolSuccinic acid

The invention relates to a paraffin inhibitor for petroleum extraction and a preparation method thereof, belonging to the technical field of paraffin inhibitors. The paraffin inhibitor for petroleum extraction is prepared from the following raw materials in parts by mass: 2-12 parts of fatty alcohol polyethenoxy ether, 2-6 parts of succinic acid, 4-12 parts of spermaceti stearic acid polyethenoxy ether, 10-19 parts of saponin powder, 1-5 parts of sodium sulfate, 2-8 parts of glyceryl monolinoleate, 3-9 parts of maleic anhydride, 15-25 parts of glycerol, 10-14 parts of ethyl acetate and 23-28 parts of ethanol. The paraffin inhibitor for petroleum extraction has excellent paraffin inhibition property (the paraffin inhibition rate is up to 90%) and favorable visbreaking property (the visbreaking rate is up to 88%). The paraffin inhibitor for petroleum extraction has the advantages of excellent high temperature resistance, excellent low temperature resistance and no equipment corrosion. The paraffin inhibitor for petroleum extraction can effectively remove blockage, thereby effectively enhancing the flowability of the oil product.

Owner:青岛蓬勃石油技术服务有限公司

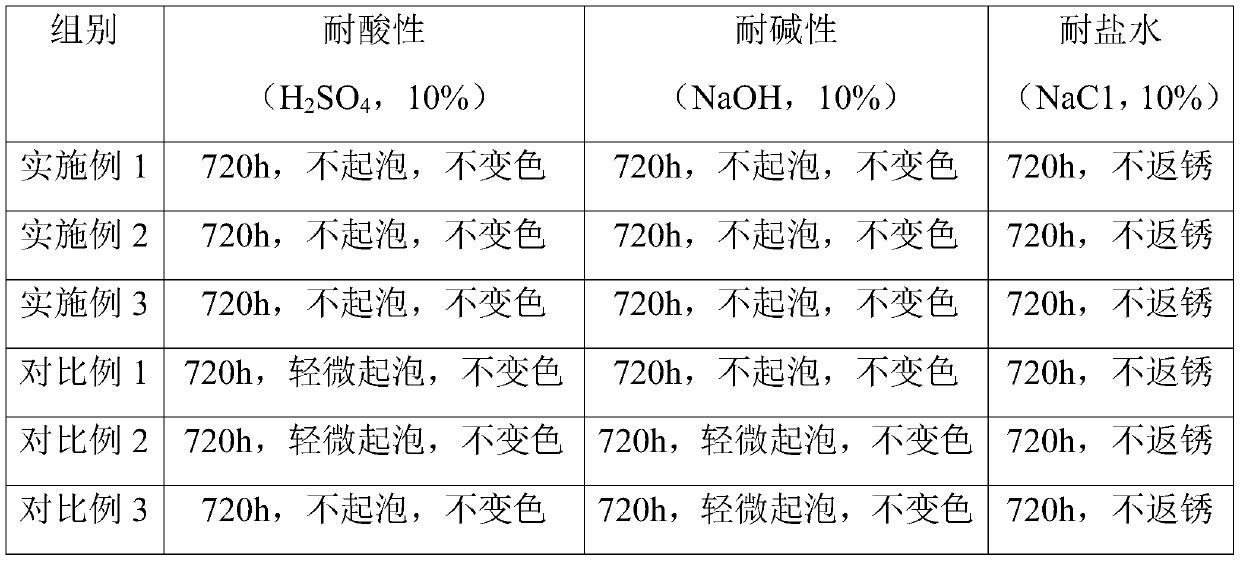

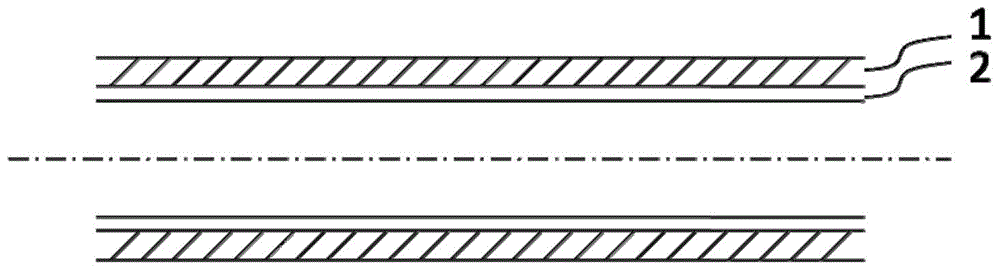

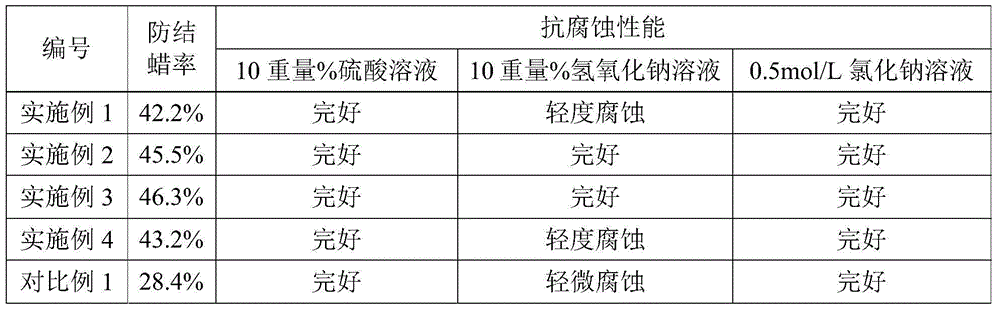

Anti-corrosion anti-wax anti-fouling coating and preparation method thereof

PendingCN110294982AGood anti-wax effectImprove anti-corrosion performanceFireproof paintsAntifouling/underwater paintsWaxOxide composite

The invention relates to an anti-corrosion anti-wax anti-fouling coating and a preparation method thereof. The coating comprises an inner layer and an outer layer; the inner layer is prepared from, byweight, 10-16 parts of polytetrafluoroethylene resin, 5-7 parts of a first filler, 8-12 parts of boron phenolic resin, 3-4 parts of the methyl methacrylate, 50-56 parts of a first solvent and 4-7 parts of a first curing agent; the outer layer is prepared from, by weight, 15-20 parts of a metronidazole modified graphene oxide composite material, 7-11 parts of polyimide resin, 3-5 parts of alpha-amino-alpha-imino-phosphonic acid inner salt, 1-2 parts of hydrophobic modified magnetic particles, 6-9 parts of a second curing agent, 5-10 parts of a second filler and 32-36 parts of a second solvent;the thickness ratio of the inner layer to the outer layer is 1:(3.2-3.6). The provided coating has a high anti-scaling rate and good anti-corrosion performance and anti-wax effect, and can be widelyapplied to tubing and casings, drill pipes, oil tubes and the like in protected oilfield exploitation.

Owner:QINGYANG ZHOUYANG MACHINERY MFG

Preparation method of oil well composite paraffin inhibitor

The invention discloses a preparation method of an oil well composite paraffin inhibitor, and belongs to the technical field of oil exploitation. The method comprises the following steps: mixing octadecyl methacrylate, maleic anhydride, styrene, an initiator and a solvent, heating and stirring the mixture, and performing a reaction to obtain a mixed solution; mixing and fermenting glass fibers, yeast powder, starch and water, adding pig blood by 0.2-0.3 time by mass of the glass fibers and hirudin by 0.02-0.03 time by mass of the glass fibers, stirring and mixing all the components, and drying, crushing and sieving the mixture to obtain modified glass fibers; and stirring and mixing, by weight, 20-30 parts of the mixed solution, 8-10 parts of the modified glass fibers, 3-5 parts of a surfactant, 20-30 parts of water, 10-20 parts of a modified additive and 10-20 parts of pretreated nano copper powder to obtain the oil well composite paraffin inhibitor. The paraffin inhibitor has an excellent paraffin inhibition effect.

Owner:李嘉诚

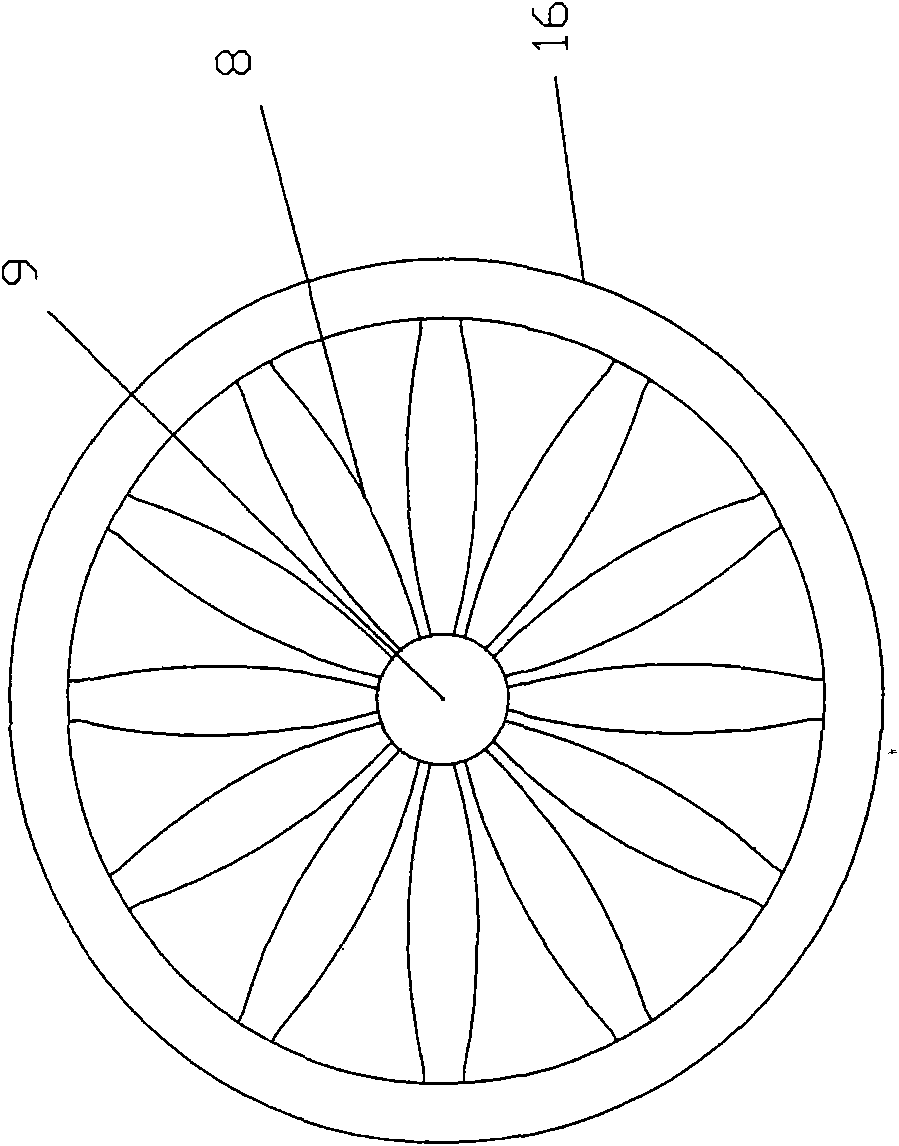

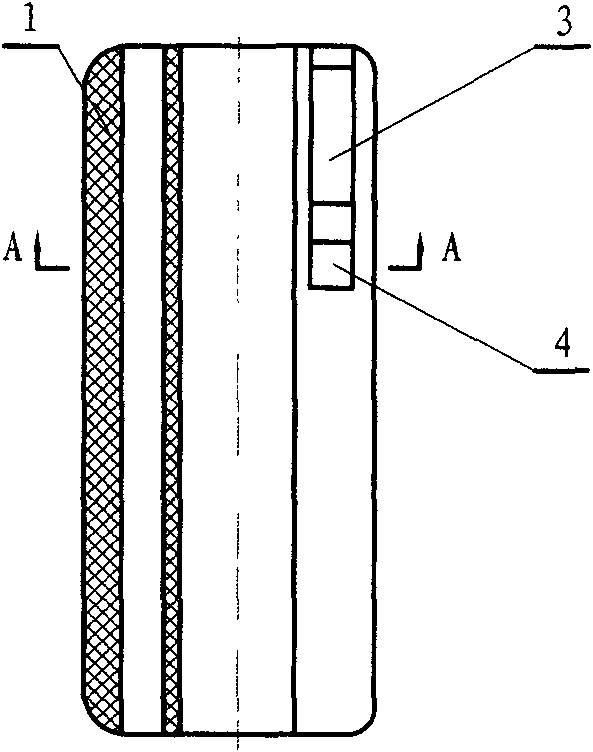

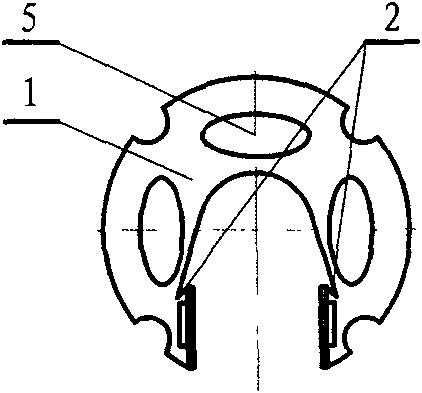

Novel sucker rod centralizer

InactiveCN101994490AImprove the diversion effectImprove the righting effectDrilling rodsDrilling casingsEngineeringMinor axis

The invention relates to a sucker rod centralizer. The sucker rod centralizer consists of a main body and a wedged body, and is characterized in that: the main body and the wedged body are provided with a plurality of deflector holes along the moving direction of the sucker rod; and the cross sections of the deflector holes are elliptical, and elliptical minor axes are arranged along the axial direction of the cross sections. The contact surfaces of the main body and the wedged body have the same shapes, the size of the wedged body is equal to that of a vacant part of the main body; and a key and a key slot, which are coupled with each other, are arranged between the outer surface of the wedged body and the inner surface of the vacant part of the main body. The novel sucker rod centralizer has the advantages of good diversion effect, large wear-resisting area, good centralizing effect, high wax resistance and the like, and is convenient to maintain.

Owner:江苏星华机场设施有限公司

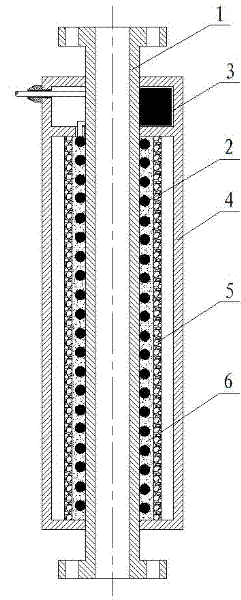

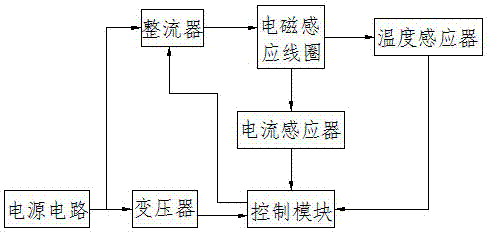

New electromagnetic anti-wax device

The new electromagnetic anti-wax device of the present invention belongs to the device for cleaning the well, and is composed of an oil delivery pipe, an electromagnetic coil and a casing. An electromagnetic coil is evenly wound on the outer wall of the oil delivery pipe, and a sheath layer is arranged outside the electromagnetic coil. The electromagnetic coil and the sheath There is filling material between the layers, and one end of the electromagnetic coil is connected with a control circuit board, and the outer side of the control circuit board and the sheath layer is integrally fitted with a casing. The control circuit board is to connect one circuit of the power supply circuit to the control module through a transformer, and connect the other circuit to the electromagnetic induction coil through a rectifier. The output of the electromagnetic induction coil controls the control module through a temperature sensor and a current sensor respectively, and the control module Connect with rectifier. The device has the advantages of simple structure, convenient dismantling, continuous operation, high reliability, low use cost, good anti-wax effect, no side effects, and little environmental pollution.

Owner:陈子清

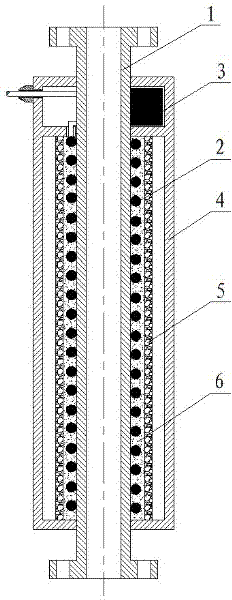

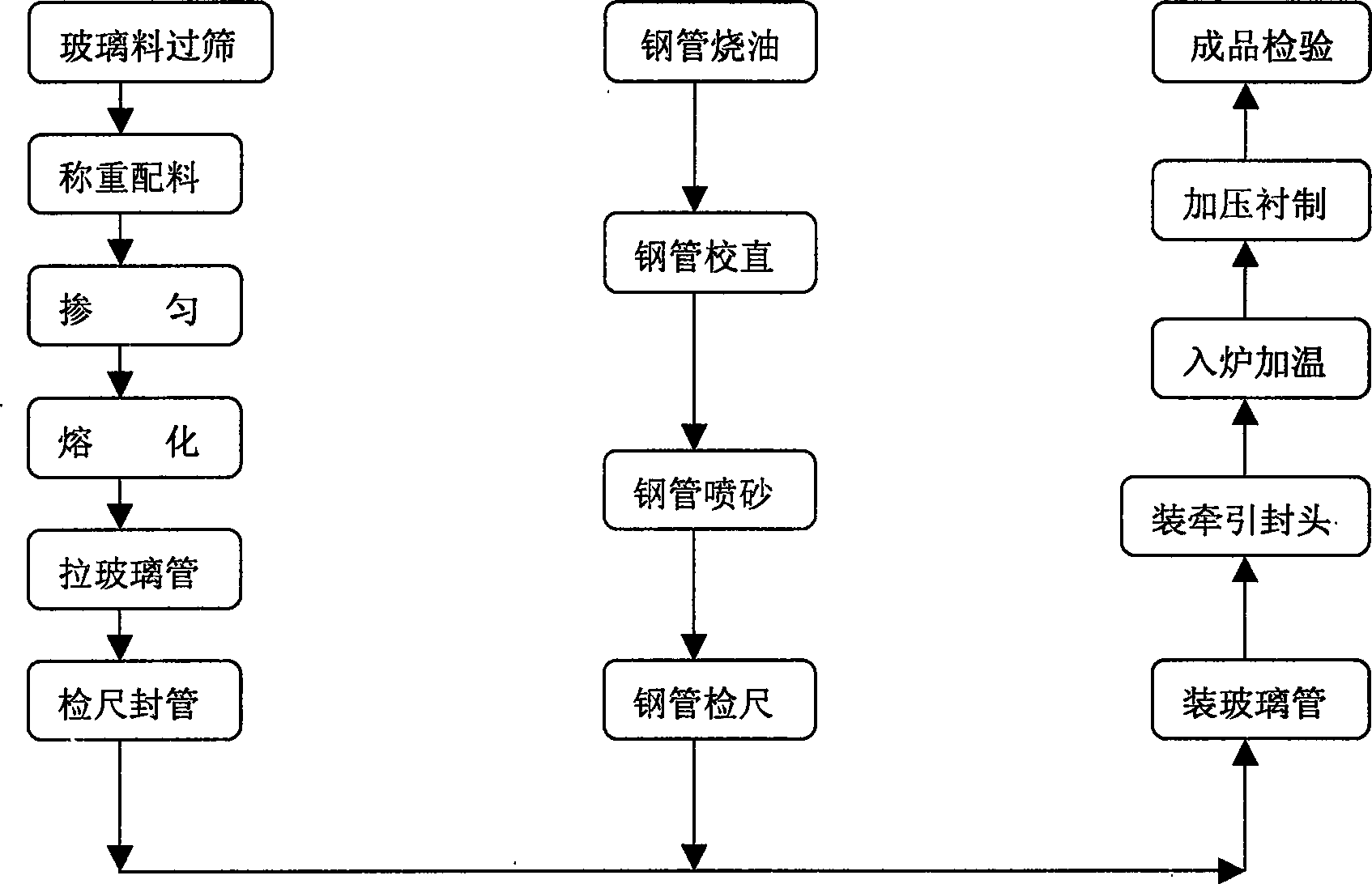

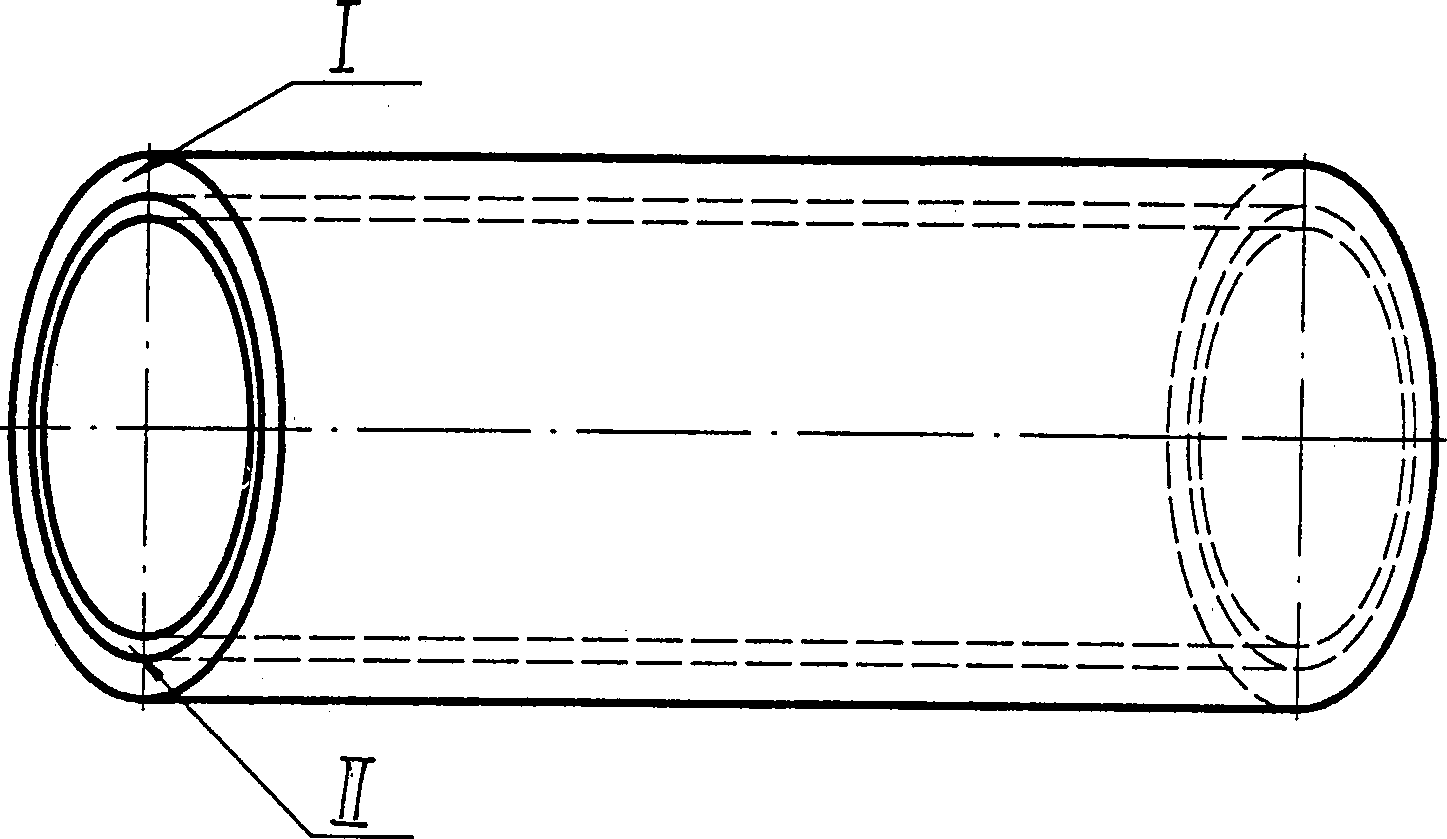

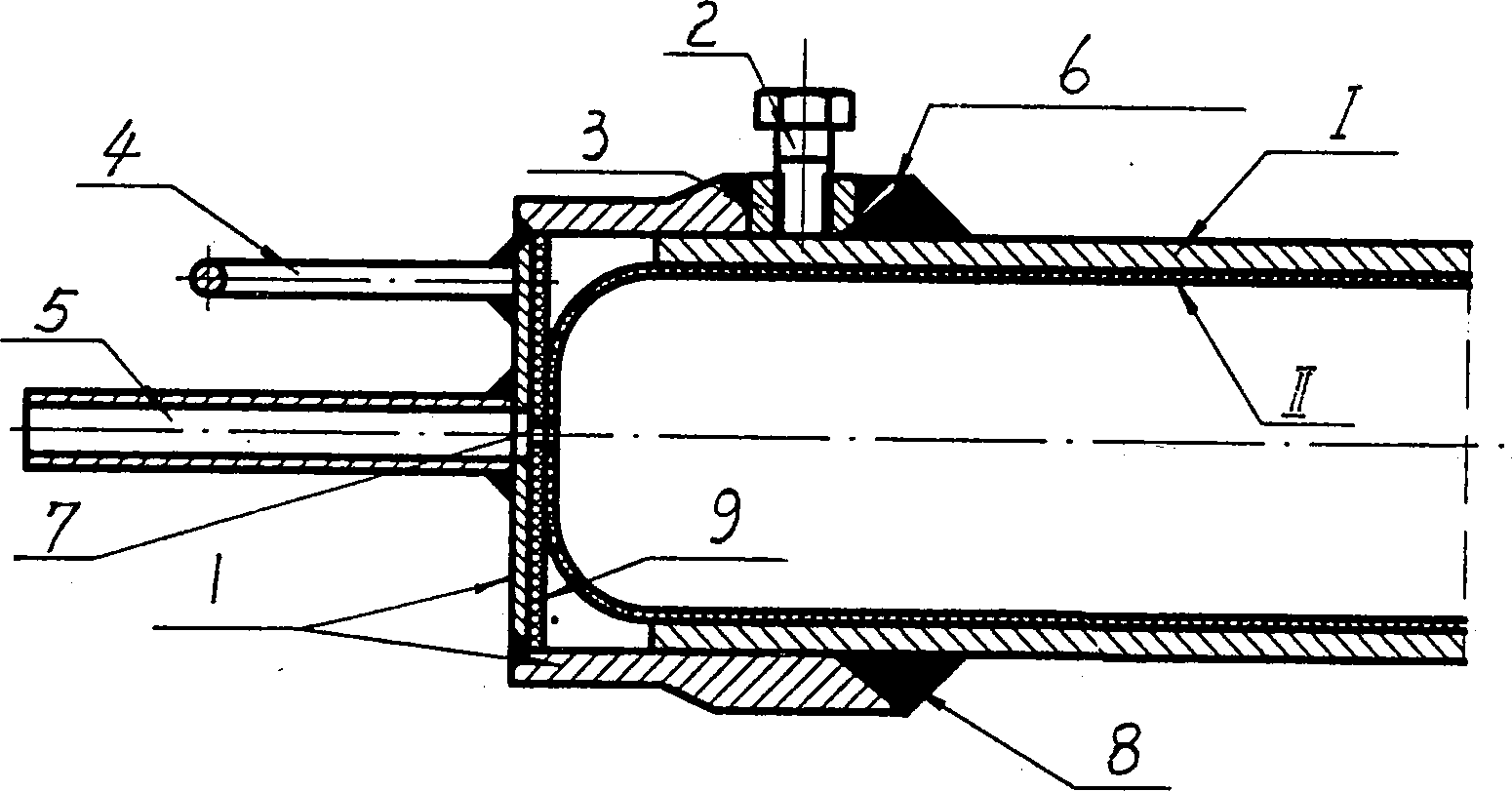

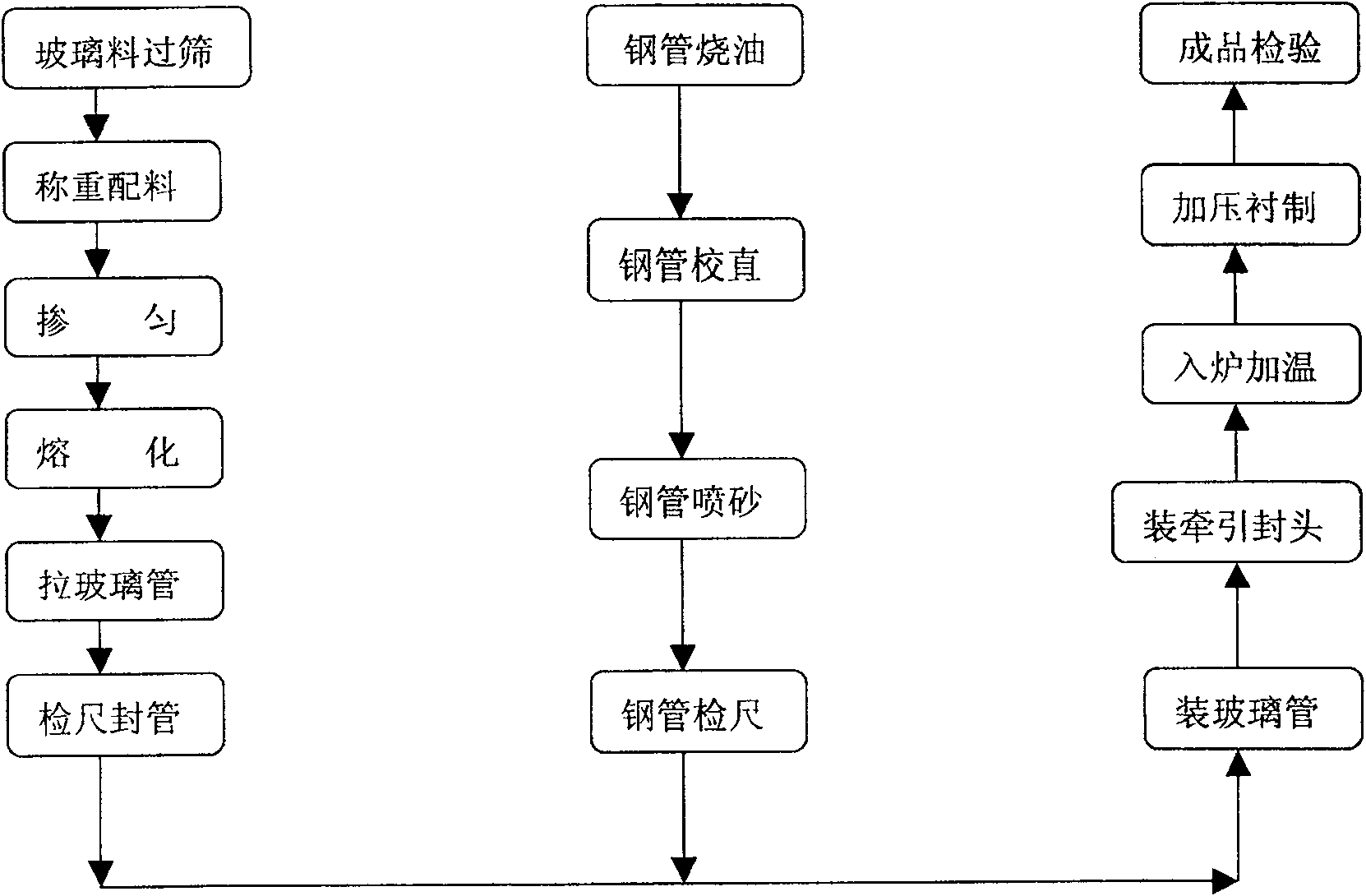

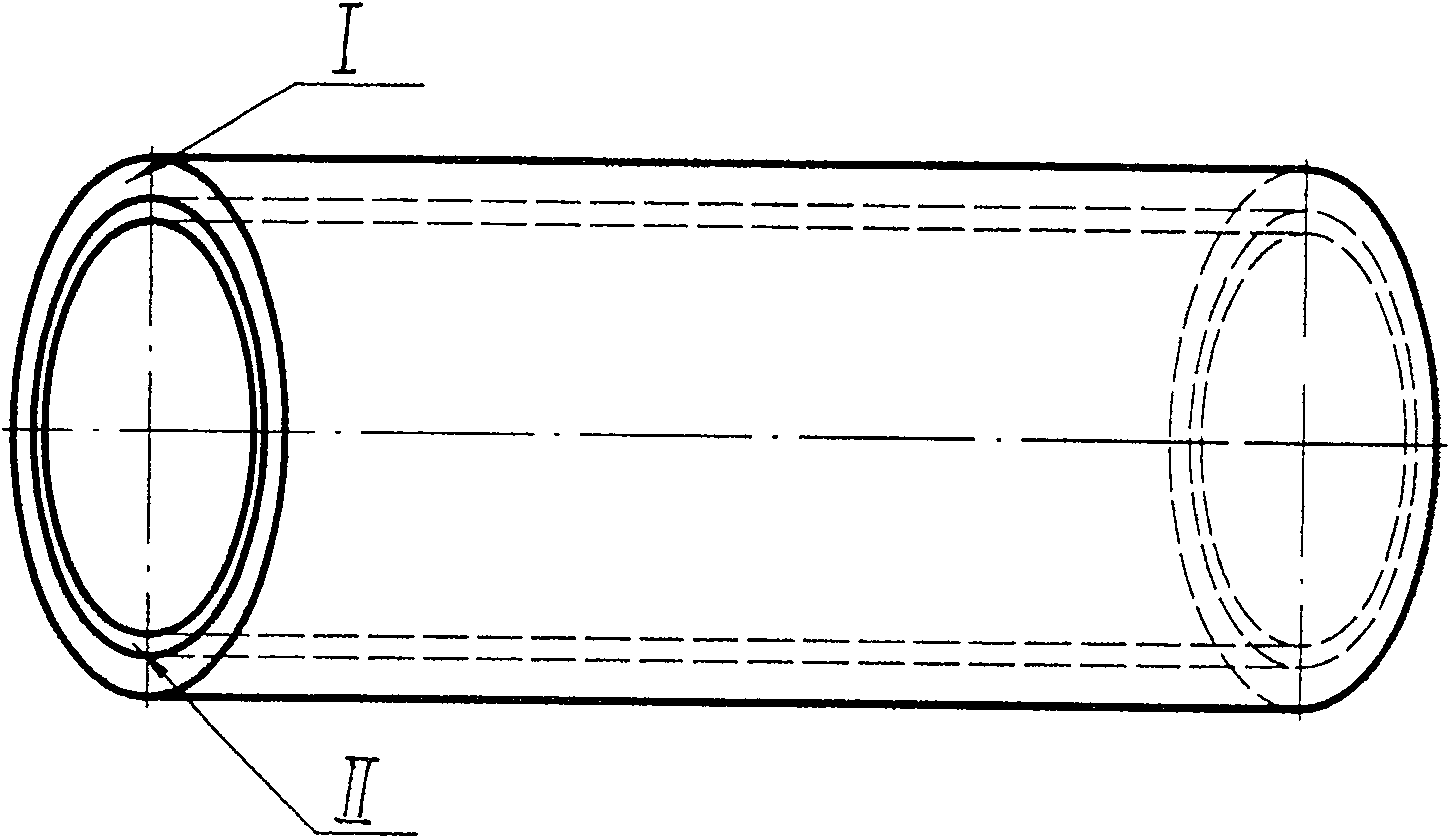

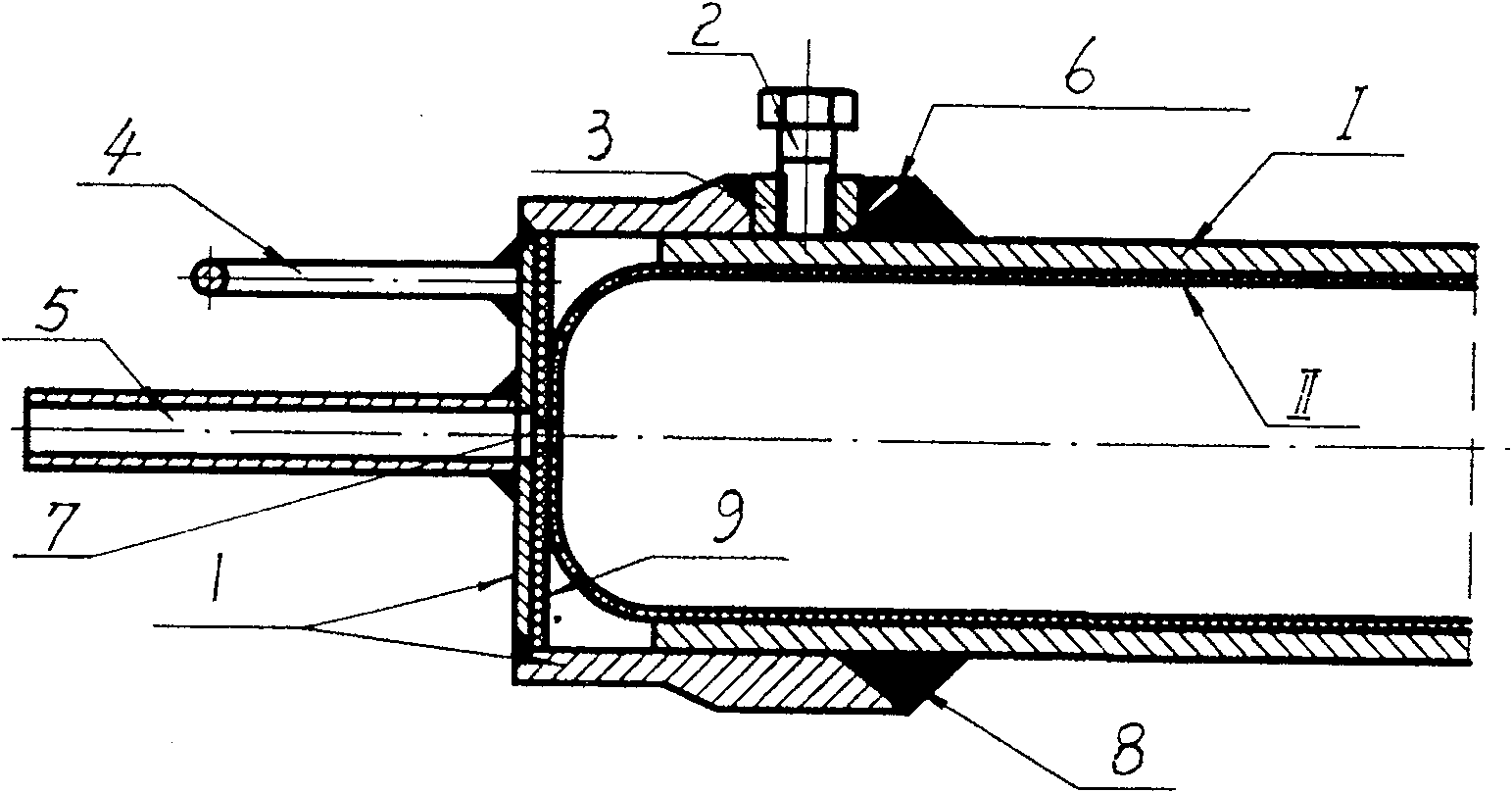

Glass products for inner lining of steel tube, and preparation method

The present invention relates to a composite steel pipe, in the concrete, it is a steel pipe product with inside lining glass. Said product is mainly used in the fields of chemical medium transmission, eccentrical wear and paraffin control of oil-well and oil pipeline buried cold transmission, etc. Said composite steel pipe product is made up by adopting three processes of making glass pipe, sandblasting steel pipe and lining steel pipe with glass pipe.

Owner:SIPING EASTOCEAN PETROCHEM EQUIP MFG

Anticorrosion waxing-preventive composite pipe and manufacturing method thereof

The invention provides an anticorrosion wax-preventive composite pipe and a manufacturing method thereof. The anticorrosion wax-preventive composite pipe comprises a pipe body (1) and a polyvinylidene fluoride layer (2) arranged on the inner wall of the pipe body (1). The anticorrosion wax-preventive composite pipe is capable of effectively preventing waxing and reducing corrosivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil wax-proofing bar and preparation method thereof

The invention discloses a crude oil wax-proofing bar and a preparation method thereof. The wax-proofing bar comprises components in parts by weight: 5-7 parts of octadecyl acrylate, 12-15 parts of 2-methyl-2-propenoic aci docosyl ester, 8-10 parts of dimethyl ethane, 2-3 parts of fatty alcohol-polyoxyethylene ether, and 65-73 parts of sodium dodecylbenzene sulfonate; and the components are mixed uniformly and then extruded into bar shape through a forming machine. The wax-proofing bar is convenient to carry and use, and has the effects of improving crude oil flowability and reducing crude oil flow resistance, good wax-proofing effect and broad application range; and the wax-proofing bar is particularly applied to flowing well and rodless pump well, and can replace manned wax removal and electrical heating wax removal of flowing well, thereby reducing the production cost of oil field and reducing the labor intensity of worker.

Owner:PANJIN LIAOHE OILFIELD YULONG RUIDA PETROLEUM TECH CO LTD

A kind of strong emulsifying microbial anti-wax agent and its application

ActiveCN104109516BStrong emulsifying abilityReduce interfacial tensionCleaning apparatusFluid removalInhibition zoneOil production

The invention discloses a strong emulsibility microbe wax cleaning and preventing bacterial agent and an application, which belongs to the oil field chemical technology field. The wax cleaning and preventing bacterial agent mainly comprises pseudomonas aeruginosa and geobacillus sp, has strong emulsification capability, and is capable of dispersing crude oil, promoting crude oil to flow, changing adherence force of borehole wall, preventing the accumulation of wax crystal on the borehole wall, and playing the paraffin inhibition and wax cleaning effects. By increasing the initial application amount of the bacteria liquid and prolong the well closing time, a stable paraffin inhibition zone can be formed due to adhesion of bacteria on borehole wall, near wellbore formation can be cleaned, and the paraffin inhibition and oil increase effects can be increased. After on-site enforcement, the well cleaning and chemical paraffin inhibition works can not be carried out in recent half year in the test wells, so that the wax cleaning and preventing bacterial agent has good paraffin inhibition effect in the well. The oil production is increased by about 30% daily, pump efficiency is increased about 10%, the surface tension of the output liquid is decreased to 20-25%, and the crude oil condensation point is decreased by 1-3 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional processor for liquid generated underground

InactiveCN101560876BGood anti-wax effectShaking/oscillating/vibrating mixersMixing methodsEngineeringCheck valve

Owner:邓海波

Preparation method of long-acting water-based paraffin inhibitor

InactiveCN108048064AAvoid breakingNot easy to gatherPipeline systemsDrilling compositionWater basedPolyvinyl alcohol

The invention discloses a preparation method of long-acting water-based paraffin inhibitor, and belongs to the technical field of oil exploitation. The method comprises the steps that a performance additive, sodium alginate liquid and saccharomycetes liquid are stirred and mixed, a sodium sulfate solution is added subsequently, stirring and mixing continue to be conducted, cooling is conducted, aglutaraldehyde solution is dropwise added, stirring and mixing continue to be conducted, the pH is adjusted, filtration and drying are conducted, and a modified microcapsule is obtained; octenyl succinic anhydride is dropwise added in polyvinyl alcohol liquid, stirring and mixing are conducted, and a primary mixture is obtained; a sodium hydroxide solution is dropwise added in the primary mixture,the pH is adjusted to be 8.3-8.5, heating and stirring are conducted, and a secondary mixture is obtained; hydrochloric acid with the mass fraction being 8%-10% is dropwise added in the secondary mixture, the pH of the secondary mixture is adjusted to be 6.8-7.1, and modified polyvinyl alcohol liquid is obtained. According to the technical scheme, the prepared long-acting water-based paraffin inhibitor has the advantages of being excellent and long-acting in paraffin control effect.

Owner:CHANGZHOU AMANTE CHEM CO LTD

Composite clear antiwax remover

The invention discloses a composite clear antiwax remover which comprises, by weight, 40-80 parts of benzenes, 10-20 parts of ethers, 10-20 parts of alcohols, 10-20 parts of phenol ether and 15-25 parts of weighting agents. The raw materials have good mutual solubility, and a coating film can be formed on the pipe wall or an oil rod, which can inhibit crystallization of wax. The composite clear antiwax remover has the advantages of safety and environmental friendliness.

Owner:西安巨力石油技术有限公司

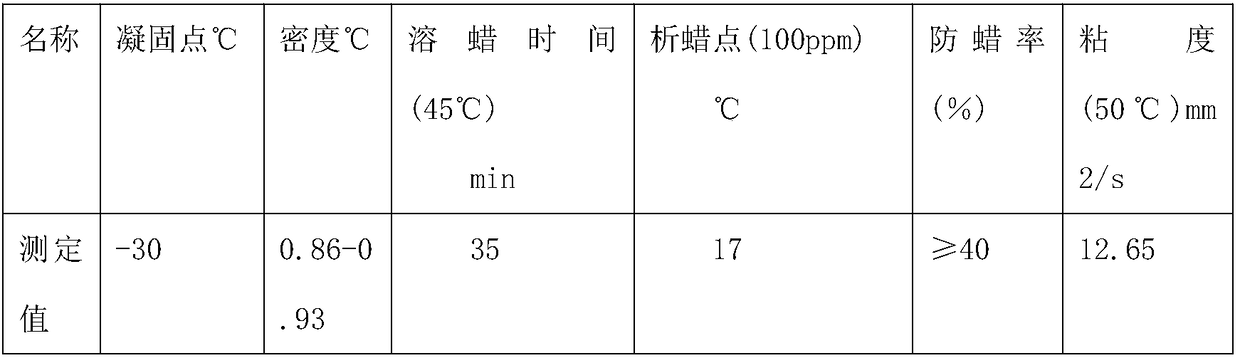

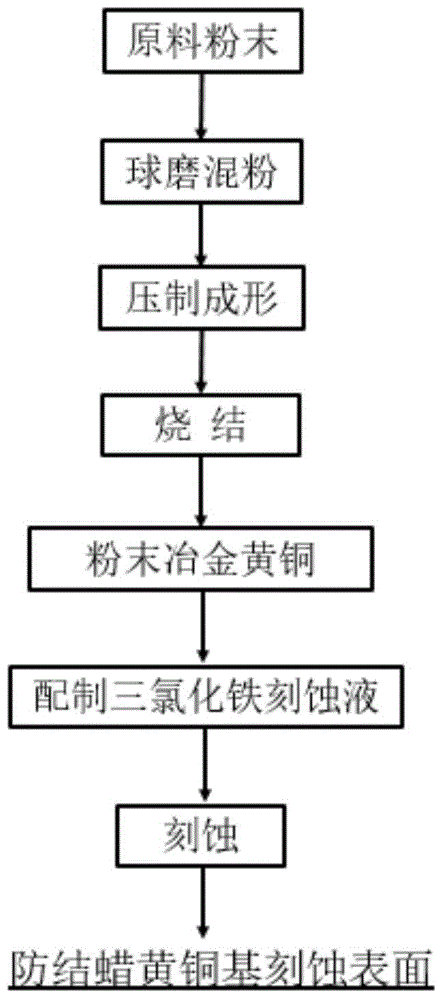

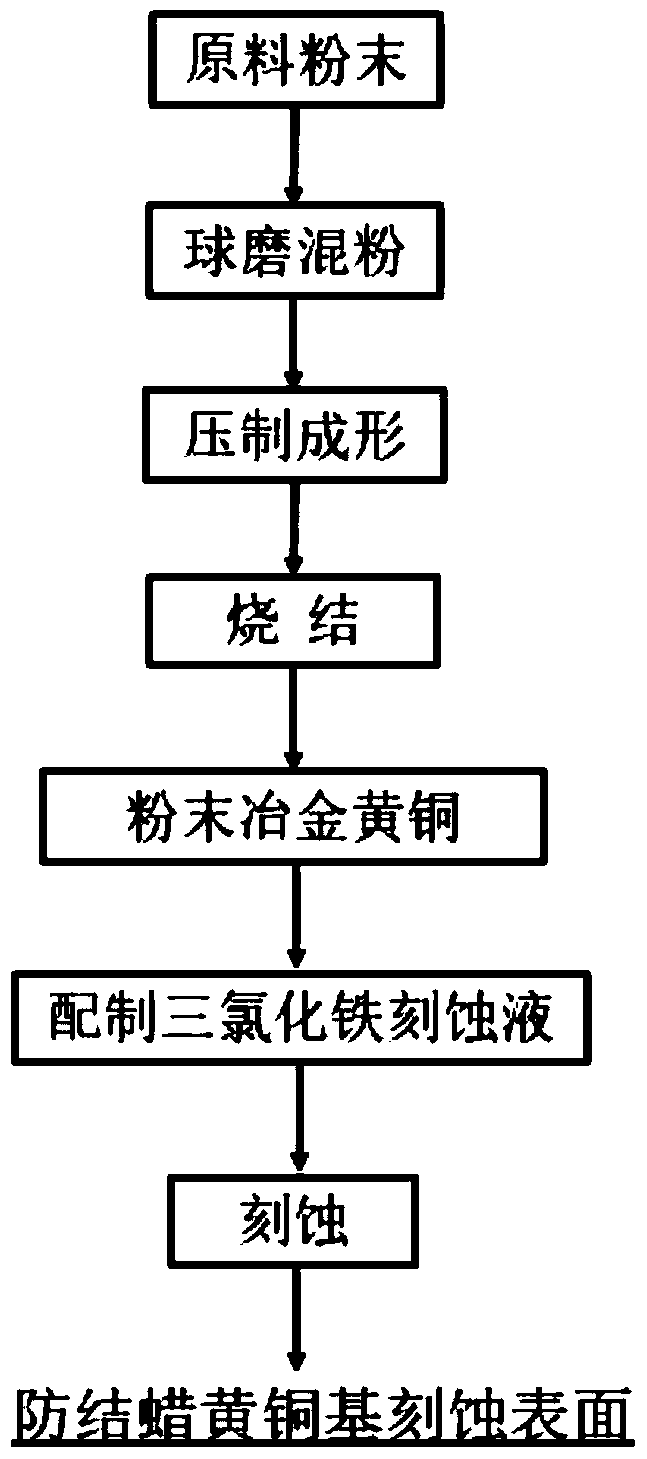

Powder metallurgy brass-based etching material with anti-paraffin-precipitation function and preparation method thereof

The invention discloses a powder metallurgy brass-based etching material with an anti-paraffin-precipitation function and a preparation method thereof. The powder metallurgy brass-based etching material with the anti-paraffin-precipitation function and the preparation method thereof are characterized in that the preparation method includes the steps that firstly, a brass-based material is prepared through the powder metallurgy method; and secondly, the brass-based material is etched through a ferric trichloride solution. A stable water film is formed on the brass-based etched surface in a water-oil-solid system to isolate contact of the oil and the surface, and accordingly paraffin in oil can not be attached to the surface of solid easily. The anti-paraffin-precipitation performance is excellent, and the powder metallurgy brass-based etching material with the anti-paraffin-precipitation function and the preparation method provide supports for developing powder metallurgy anti-paraffin-precipitation devices of complex structures.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

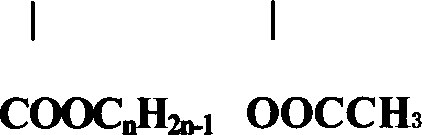

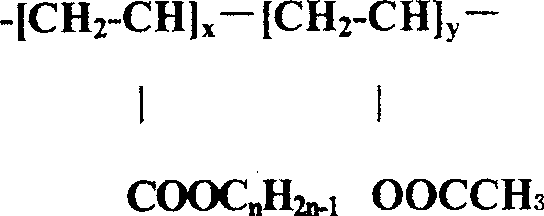

Solid polymer slow-release paraffin control ball and preparation method and use method thereof

InactiveCN112360396AUnlimited extension of wax protection periodExtended wax protection periodCleaning apparatusDrilling compositionSurface-active agentsMaterials science

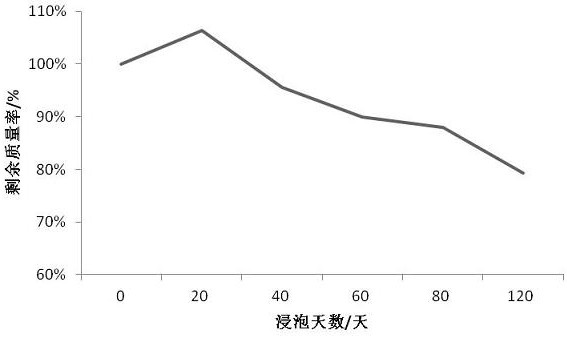

The invention provides a solid polymer slow-release paraffin control ball and a preparation method and a use method thereof. The solid polymer slow-release paraffin control ball is formed by a high-molecular polymer, a surfactant, a density regulator and an oil auxiliary agent through high-temperature and high-pressure blending injection molding, and paraffin precipitation of a wellbore pipe rod of a producing well is delayed and prevented through the combined action of the high-molecular polymer and the surfactant, the high-molecular polymer has a long-chain alkyl structure similar to a wax molecule, and a polar chain link part of the high-molecular polymer enables a wax crystal and a crystal form to be distorted, so that the wax crystal is prevented from continuously depositing and growing; and the surfactant is adsorbed on the wax crystal surface or the wax precipitation surface, so that the polarity of the wax crystal surface is reversed, and the wax control effect is achieved. Thesolid polymer slow-release paraffin control ball is periodically and quantitatively added into an oil jacket annulus from a wellhead manually or in cooperation with automatic filling equipment, can directly reach an oil layer or a designed position, slowly and stably releases effective components in the oil well produced liquid soaking process, prolongs the paraffin removal period, reduces the oil well production cost, and guarantees the production efficiency and the crude oil yield.

Owner:PETROCHINA CO LTD

Paraffin remover and inhibitor and preparation method thereof

PendingCN114591510AExcellent Surfactant PropertiesGood for wax removalDrilling compositionFatty substance recoveryXylyleneHydroxy group

The invention discloses a paraffin remover and inhibitor and a preparation method thereof.The preparation method comprises the following steps that firstly, polyethylene polyamine and 1, 1, 2, 2-tetra (4-hydroxyphenyl) ethane are added into a reaction kettle, and the mixture is heated to be completely dissolved; secondly, raising the temperature under a stirring condition, gradually dropwise adding formaldehyde when the temperature is raised to 60 DEG C, continuously reacting for 2 hours, and then adding xylene; thirdly, raising the temperature to 140 DEG C, adding KOH into the reaction kettle, uniformly stirring, vacuumizing, and reducing the temperature to 100 DEG C; then, adding PO into the reaction kettle, and reacting for 2 hours under the conditions that the pressure is 0.3 MPa and the temperature is 135 DEG C; then, reducing the temperature to 120 DEG C under the condition that the pressure is not reduced, continuously adding KOH and EO, and reacting for 2 hours under the conditions that the pressure is 0.3 MPa and the temperature is 120 DEG C; and finally, adding acid liquor into the reaction kettle to neutralize residual KOH, extracting the mixture, and removing the solvent to obtain the paraffin remover and inhibitor. The paraffin remover has excellent surface activity and excellent paraffin removal and control effects, and can provide technical support for oil and gas exploitation.

Owner:四川澳凯化工有限公司

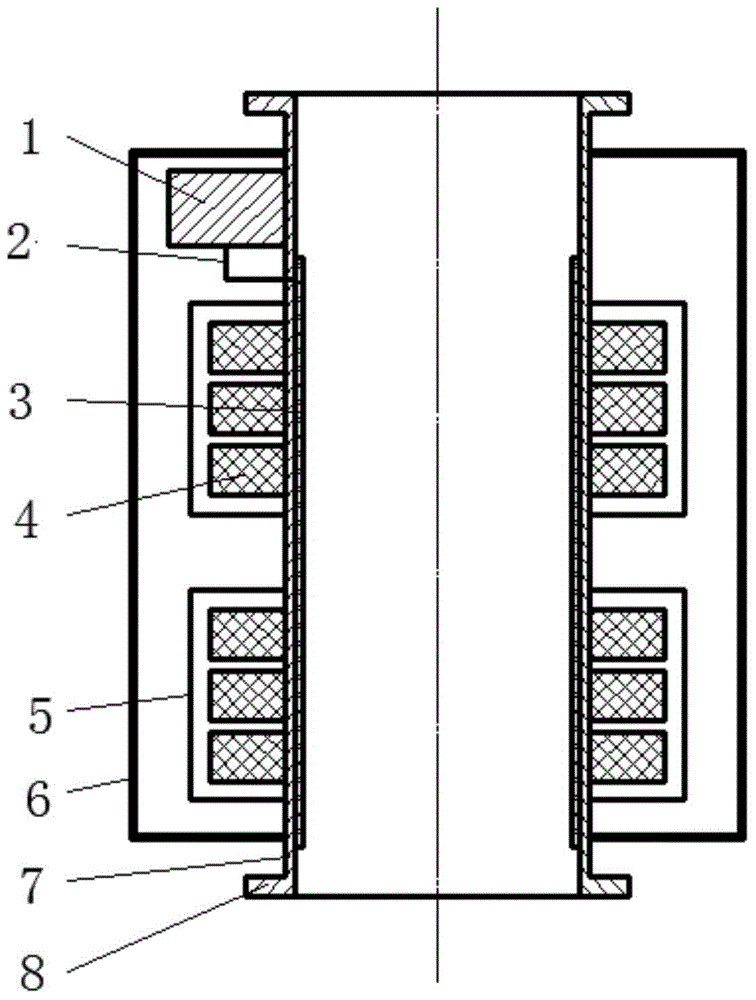

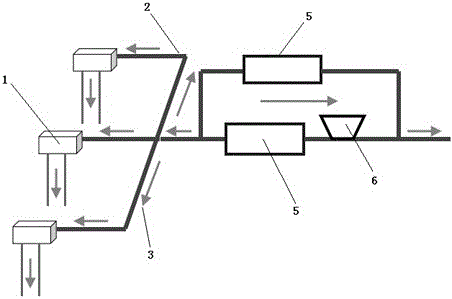

Multi-well-group electromagnetic wax control transmission device and method

ActiveCN106223901ATo achieve the purpose of wax preventionGood anti-wax effectTransformers/inductances coolingCleaning apparatusWaxTemperature control

The invention relates to a multi-well-group electromagnetic wax control transmission device and method. The device and the method have the technical scheme that a plurality of parallel connection production oil wells are connected with one side of a pipe column; one side of the pipe column is connected with a ground oil conveying pipeline; an electromagnetic wax control device is arranged on the ground oil conveying pipeline; the electromagnetic field transmission direction is along the pipe column; the right side of a controller is provided with a center pipe; the outer side of the middle of the center pipe is provided with an electromagnetic conversion main body; the upper end and the lower end of the center pipe are provided with connection hoops; a temperature control protection material layer is arranged at the outer side of the center pipe; an insulation liquid oil layer is arranged at the outer side of a coil layer; a sealing connector is arranged at the outer side of each of the upper end and the lower end of the center pipe; an oil pipe connector is arranged at the outer side of each sealing connector. The device and the method have the beneficial effects that the device and the method can be simultaneously applied to the wax control of the plurality of parallel connection well groups and ground pipelines; the wax control effect is good; the effect can be achieved for a plurality of wells at the same time; the device is arranged on the wellhead flow process, and is connected into a whole with the oil conveying pipeline; the equipment can be installed at any time; the production halt or underground operation is not needed.

Owner:张振海

Wax-proof condensation-reducing cool temperature convey agent

ActiveCN1995268AReduce energy saving and consumption reductionHigh drop rateDrilling compositionParaffin waxComponents of crude oil

The invention discloses a wax-proof pour point depression cold transmitting agent of dilute oil well, which is characterized by the following: controlling the sediment on the oil pipe and oil extract rod and exterior output pipe through the quantity of dispersant of wax in the crude oil; reducing solidifying point of crude oil greatly; forming small wax ball with diameter at 0.03mm in the light component of crude oil.

Owner:PETROCHINA CO LTD

Wax-proof condensation-reducing cool temperature convey agent

ActiveCN100513511CReduce energy saving and consumption reductionHigh drop rateDrilling compositionParaffin waxEngineering

The invention relates to a wax-preventing and decondensing cooling agent for thin oil wellbore and external transportation pipelines. Wax crystal dispersants are added to crude oil to control the deposition of wax on oil pipes, sucker rods and external transportation pipelines. Significantly lower the freezing point of crude oil, alleviate wax deposition in oil wells, and ensure normal production of high-wax wells. A variety of high molecular polymers are used to link wax-friendly straight-chain saturated hydrocarbon groups similar to the paraffin structure contained in crude oil on the straight chain of the high polymer, forming small wax balls with a diameter of about 0.03mm suspended in the light components of crude oil Among them, the structural strength is reduced, and it is difficult to form a network structure with each other, so the low-temperature fluidity is also improved, and the freezing point is also lowered.

Owner:PETROCHINA CO LTD

A powder metallurgy brass-based etching material with anti-wax function and preparation method thereof

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Glass products for inner lining of steel tube, and preparation method

The invention relates to a composite steel pipe, in particular to a steel pipe lined glass product. The steel pipe lined glass product is mainly used in the fields of chemical medium transportation, prevention of eccentric wear and wax deposition in oil pumping wells, and buried cold transportation of oil pipelines. The product of the invention is manufactured through three process steps: glass tube production, steel tube sandblasting pretreatment and steel tube lining production. As a newly developed pipeline anti-corrosion technology, steel pipe lining glass technology can effectively solve the corrosion and wax deposition problems of chemical and oil field pipelines, as well as wear and eccentric wear. It has excellent corrosion resistance, excellent wax resistance, and anti-corrosion. Grinding, and can withstand higher temperature, which is also the product and manufacturing process involved in the present invention.

Owner:SIPING EASTOCEAN PETROCHEM EQUIP MFG

Oil-based paraffin remover and inhibitor

InactiveCN105062450AGood anti-wax effectObvious Wax Removal AdvantageDrilling compositionMaleic anhydrideChemistry

The invention discloses an oil-based paraffin remover and inhibitor composed of a paraffin remover and paraffin inhibitors. The paraffin remover is composed of, by weight, 20-45% of 90-120# petroleum ether, 25-60% of cyclohexane and 20-50% of kerosene; the paraffin inhibitors are composed of a paraffin inhibitor I and a paraffin inhibitor II, the paraffin inhibitor I is composed of octadecyl acrylate and styrene, the weight ratio of octadecyl acrylate to styrene is 14:1, the paraffin inhibitor II is composed of octadecyl acrylate and maleic anhydride, and the weight ratio of octadecyl acrylate to maleic anhydride is 28.6:1; the oil-based paraffin remover and inhibitor comprises, by weight, 70-95% of the paraffin remover, 2.5-15% of the paraffin inhibitor I and 2.5-15% of the paraffin inhibitor II. The oil-based paraffin remover and inhibitor has the advantages that the paraffin inhibition effect of a high-molecular polymer with octadecyl acrylate and styrene as raw materials is the best, paraffin inhibition rate analysis is carried out on oil samples, and the paraffin inhibition rate can reach over 40%.

Owner:CHINA PETROLEUM & CHEM CORP

Special solid crude oil wax preventer for wax preventer

ActiveCN107057669BOn-site construction is simpleLow costDrilling compositionCarvacryl acetateOleic Acid Triglyceride

The invention discloses a special solid crude oil paraffin inhibitor for a paraffin controller, and belongs to the technical field of crude oil paraffin inhibitor. The invention solves the technical problems that the existing crude oil paraffin inhibitor is stored in a wellbore, the period of regularly cleaning paraffin is short and the cost of regularly cleaning the paraffin is high. The solid crude oil paraffin inhibitor is prepared from an ionic fluorate type surfactant, an ionic citrate type surfactant, a nonionic citrate ester type surfactant, an organic montmorillonite and a quaternary copolymer by blending and injecting; the quaternary copolymer is prepared from monomeric acrylic acid high-carbon alcohol ester, vinyl acetate, oleic acid high-carbon alcohol ester and styrene by polymerizing. The paraffin inhibiting effect of the solid paraffin inhibitor matched with the paraffin controller is significant; the paraffin precipitation can be effectively inhibited in the process of oil recovery; the period of regularly cleaning the paraffin in the wellbore is greatly reduced; the oil recovery cost is reduced; the safe and stable operation of oil wells is ensured.

Owner:NORTHEAST GASOLINEEUM UNIV +1

A method for releasing the hysteresis of sucker rod descending in polymer flooding production well

ActiveCN105298458BSolve the problem of down lagLow degradation costCleaning apparatusFluid removalOrganic chemistryViscosity

The present invention relates to a method for releasing the downward hysteresis of the sucker rod in the polymer flooding production well. The method for releasing the downward hysteresis of the sucker rod in the polymer flooding production well is to add medicine by dripping at the wellhead to the pumping well in normal production. method, adding polyepichlorohydrin amine, oxidant, corrosion inhibitor, and scale remover, wherein, the amount of polyepichlorohydrin amine added is 0.5%~0.8% of the mass of the pumping well production fluid, and the amount of oxidant added It is 0.3%~0.7% of the mass of the pumping well produced fluid, the addition of corrosion inhibitor is 0.1% of the mass of the pumping well produced fluid, and the addition of scale remover is 2% of the mass of the pumping well produced fluid ~4%, polyepichlorohydrin amine and polyacrylamide in the production fluid form an ultra-low viscosity association colloid solution, which makes the production fluid easy to be extracted from the ground. In the present invention, the polyepichlorohydrin amine and the polyacrylamide in the production fluid form an ultra-low-viscosity association colloid solution, which makes the production fluid easy to be extracted from the ground, and solves the problem of the downward lag of the polymer flooding pumping unit , Low degradation cost.

Owner:NORTHEAST GASOLINEEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com