Anticorrosion waxing-preventive composite pipe and manufacturing method thereof

A composite pipeline and anti-wax technology, which is applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, chemical instruments and methods, etc., can solve the problem that oil production pipelines cannot have both wax anti-wax effect and anti-corrosion performance at the same time, and achieve good chemical performance. Stability, reduced free energy and roughness, reduced deposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

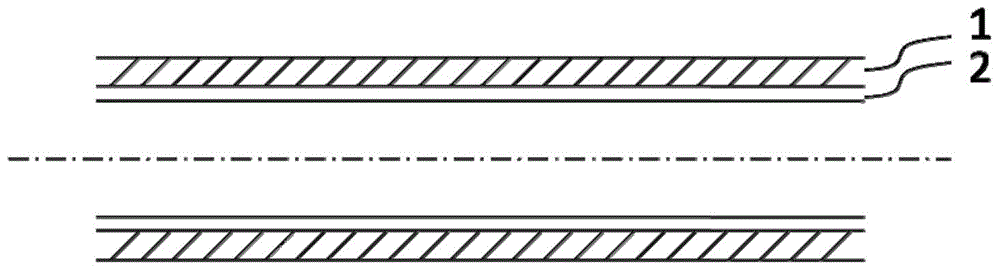

[0025] The preparation method of the anti-corrosion and wax-proof composite pipe provided by the present invention includes forming a polyvinylidene fluoride layer 2 on the inner wall of the pipe body 1.

[0026] According to the present invention, the method of forming the polyvinylidene fluoride layer 2 can be performed by various existing methods. For example, polyvinylidene fluoride can be dissolved in a diluent to prepare a slurry, and then the slurry can be coated Cover the inner wall of the pipe body 1, and then remove the diluent in the slurry. Wherein, the coating method is well known to those skilled in the art, for example, brush coating, curtain coating, spray coating, etc. can be used. In addition, the method for forming the polyvinylidene fluoride layer 2 can also be to first prepare polyvinylidene fluoride into a polyvinylidene fluoride film, and then heat-press the obtained polyvinylidene fluoride film on the inner wall of the tube body 1 to A polyvinylidene fluo...

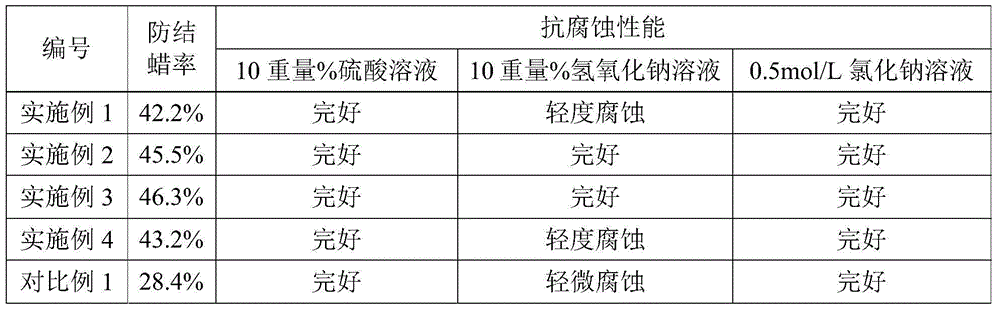

Embodiment 1

[0038] This embodiment is used to illustrate the anti-corrosion and wax-proof composite pipe provided by the present invention and the preparation method thereof.

[0039] First, the carbon steel pipe is pretreated with oil and rust surface to obtain a clean surface, and then the carbon steel pipe obtained by the surface pretreatment is heated to 200°C, and then a polyvinylidene fluoride film with a thickness of 52μm (wherein, polyvinylidene fluoride) The number average molecular weight of vinyl fluoride is 100,000) is wound on a calender roll and fed into the carbon steel pipe. The carbon steel pipe is slowly rotated at a speed of 3 rpm, and the polyvinylidene fluoride film is uniformly pressed to the inner tube of the carbon steel pipe at a pressure of 5 MPa On the wall, the heating is stopped after the rolling is uniform, while the carbon steel pipe continues to rotate until solidified, and an anti-corrosion and wax-proof composite pipe G1 including the pipe body 1 and the poly...

Embodiment 2

[0041] This embodiment is used to illustrate the anti-corrosion and wax-proof composite pipe provided by the present invention and the preparation method thereof.

[0042] First, the carbon steel pipe is pretreated with degreasing and rust removal in advance to obtain a clean surface, and then the carbon steel pipe obtained by the surface pretreatment is heated to 280°C, and then a polyvinylidene fluoride film with a thickness of 80μm (wherein, polyvinylidene fluoride) The number average molecular weight of vinyl fluoride is 410,000) is wound on a calender roll and fed into the carbon steel pipe. The carbon steel pipe is slowly rotated at a speed of 5 rpm, and the polyvinylidene fluoride film is uniformly pressed to the inner tube of the carbon steel pipe at a pressure of 5 MPa On the wall, the heating is stopped after the rolling is uniform, while the carbon steel pipe continues to rotate until solidified, and an anticorrosive and wax resistant composite pipe G2 including the pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com