Preparation method for high-impact-strength anti-photooxidation-aging polypropylene

A polypropylene and high-impact technology, which is applied in the field of polymer material preparation, can solve the problems that polypropylene cannot form β-crystals and does not have β-nucleation, and achieves excellent photo-oxidative aging resistance, excellent comprehensive mechanical properties, The effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] (1) Calcium acetate is dissolved in water, and calcium acetate aqueous solutions with different concentrations of 0.01% to 10% are prepared;

[0030] (2) Nano-TiO 2 Add the above-mentioned calcium acetate aqueous solution, stir and mix, then filter, and dry at 160-200°C. After heat treatment, the calcium acetate is decomposed and converted into calcium carbonate, so that the surface of the nano inorganic anti-ultraviolet additive is coated with a layer of calcium carbonate;

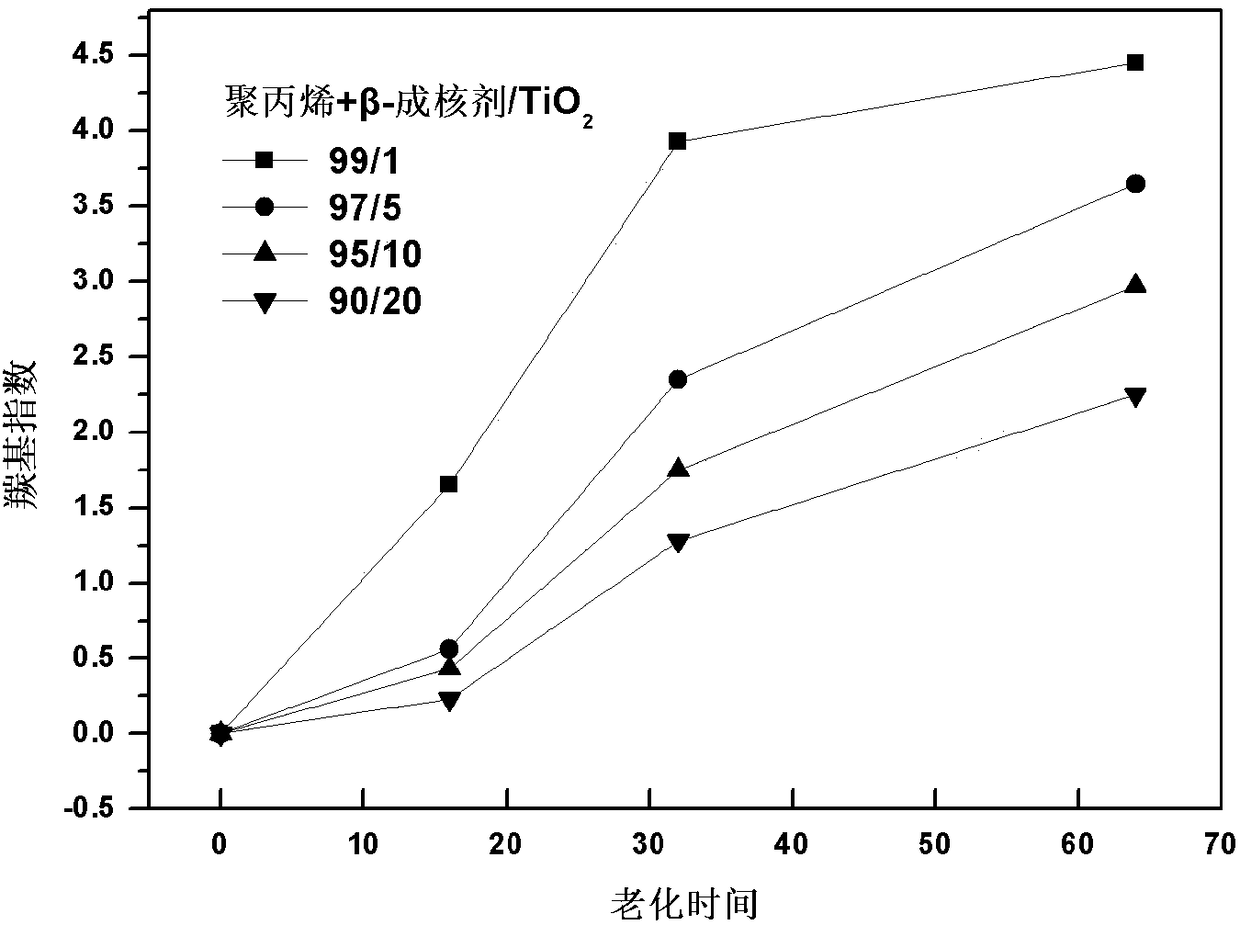

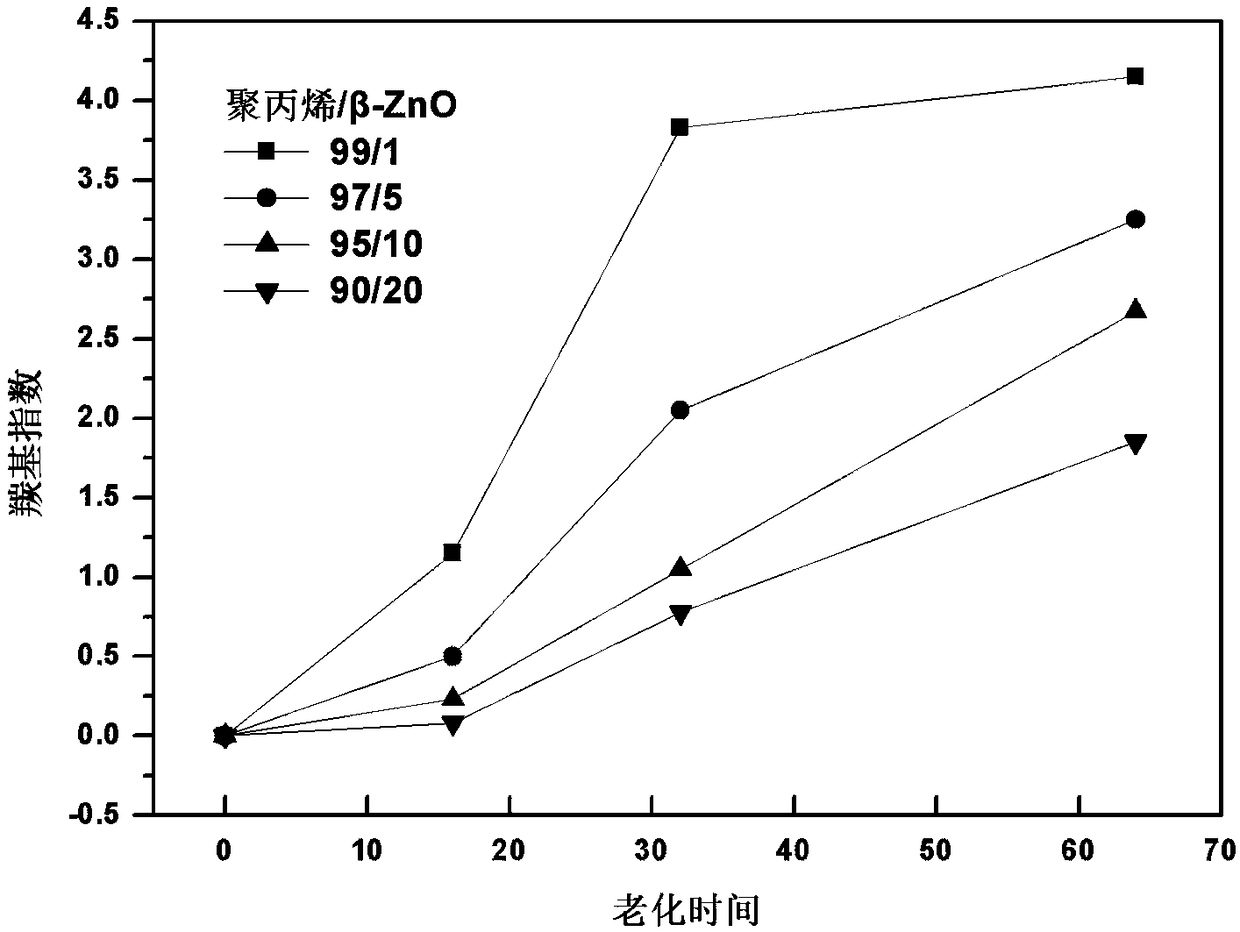

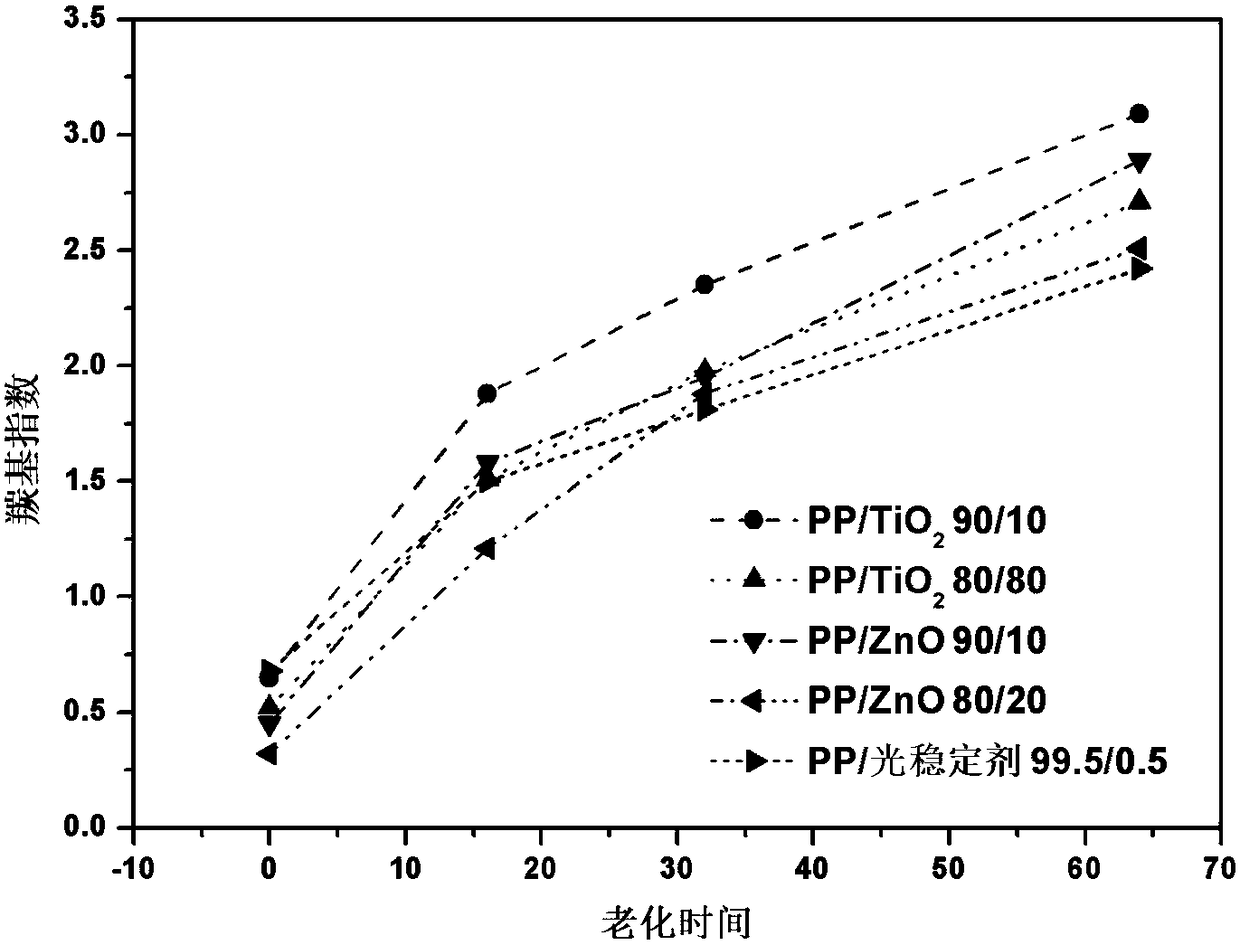

[0031] (3) the modified nano-TiO processed through step (2) 2 Mix according to the mass ratio of polypropylene and β-crystal nucleating agent 1~20:99~80, wherein the mass ratio of polypropylene and β-crystal nucleating agent is 100:0.1~2, mix evenly and melt extrude out, the extrusion temperature is 190-220°C, and the screw speed is 30-60rpm.

[0032] Specifically, the concentration of calcium acetate aqueous solution and the type of β-nucleating agent in Examples 1-7 and Comparative Examples 1-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com