Glass products for inner lining of steel tube, and preparation method

A manufacturing method and technology of steel pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of wear resistance, different elastic coefficients of surface and core, and high temperature resistance, and avoid corrosion temperature. Environment, excellent chemical and physical properties, good resistance to thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

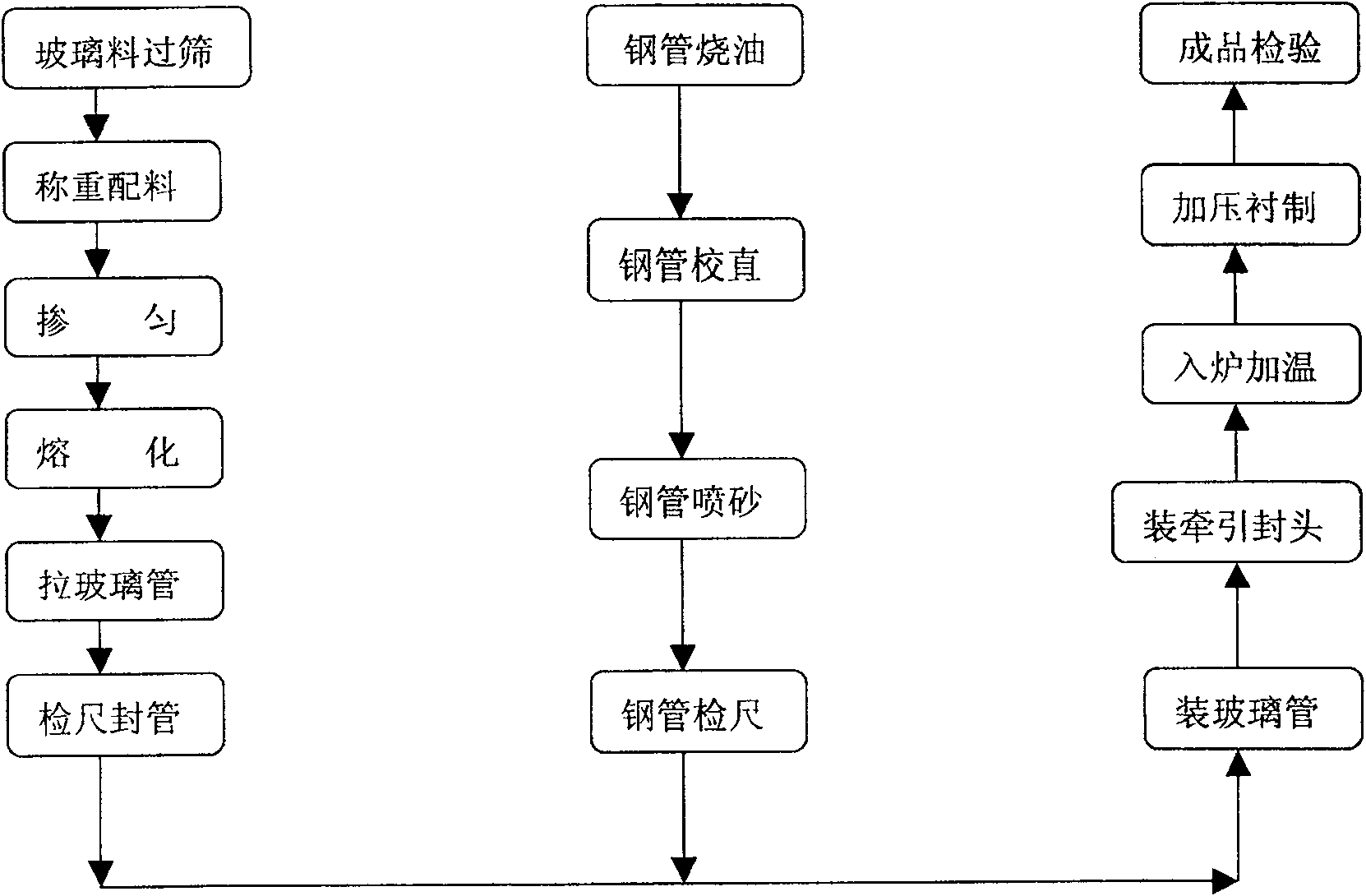

Method used

Image

Examples

Embodiment Construction

[0039] The main equipment for preparing the product of the present invention includes:

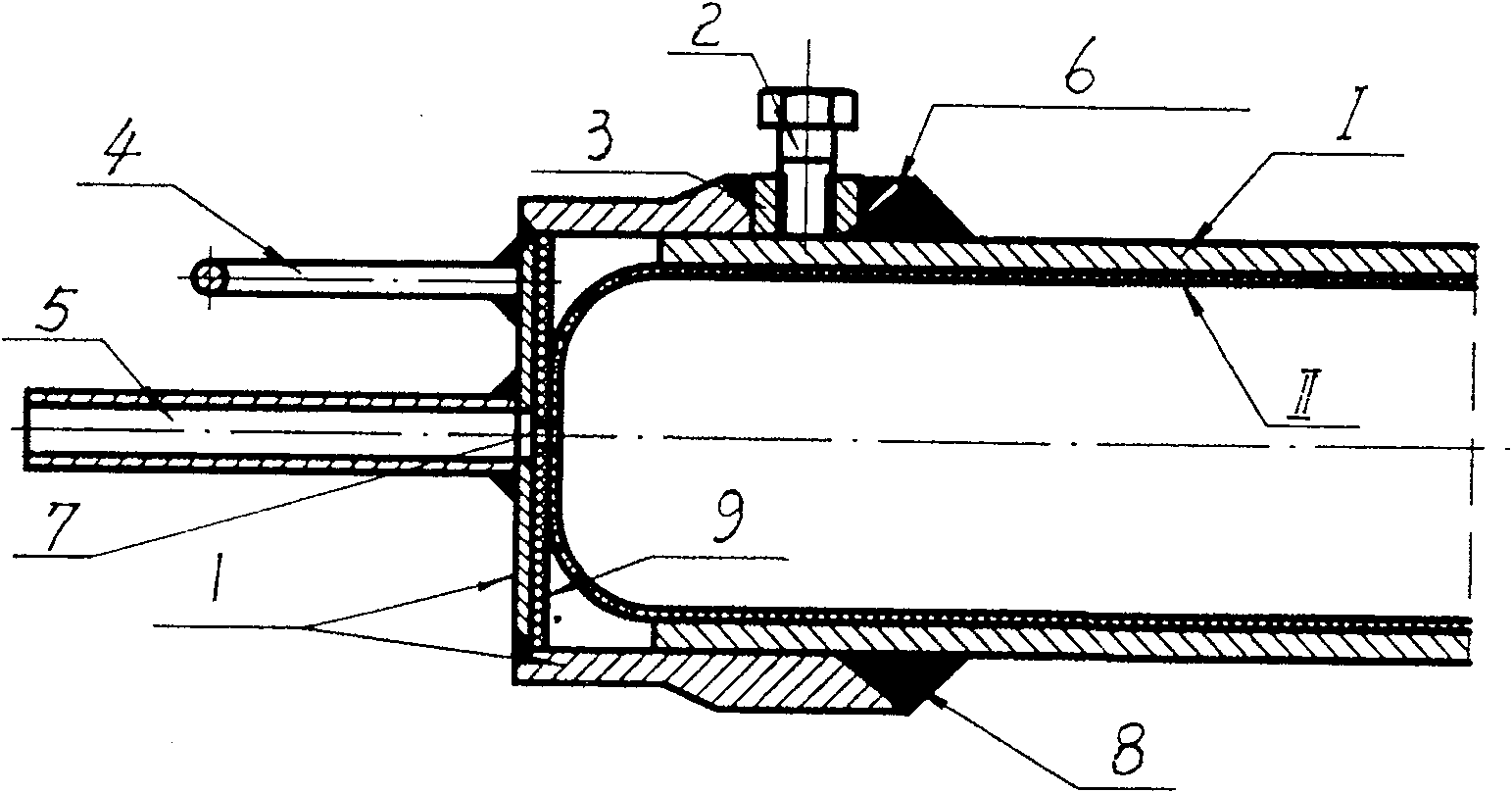

[0040] Reciprocating vibrating sieve (glass material mixed evenly); glass melting furnace 4-12 hole round furnace, melting crucible is 80-130L; sandblasting air compressor is 3-20M 3 / min; 0.1~1.0M for sandblasting tank 3 ;The liner furnace is a 4-10-hole resistance band heating furnace, with a length of 4000-6000mm, a width of 1200-3000mm, a height of 1200-2500mm, two to three sections of temperature, 300-600 of low-temperature section, and 400-700 of medium-temperature section , high temperature section 500-800, traction speed 160-200mm / min, 4-9 rows of supports behind the furnace, 7.5-11 meters long, 6-15 rows of supports in front of the furnace, 8-14 meters long.

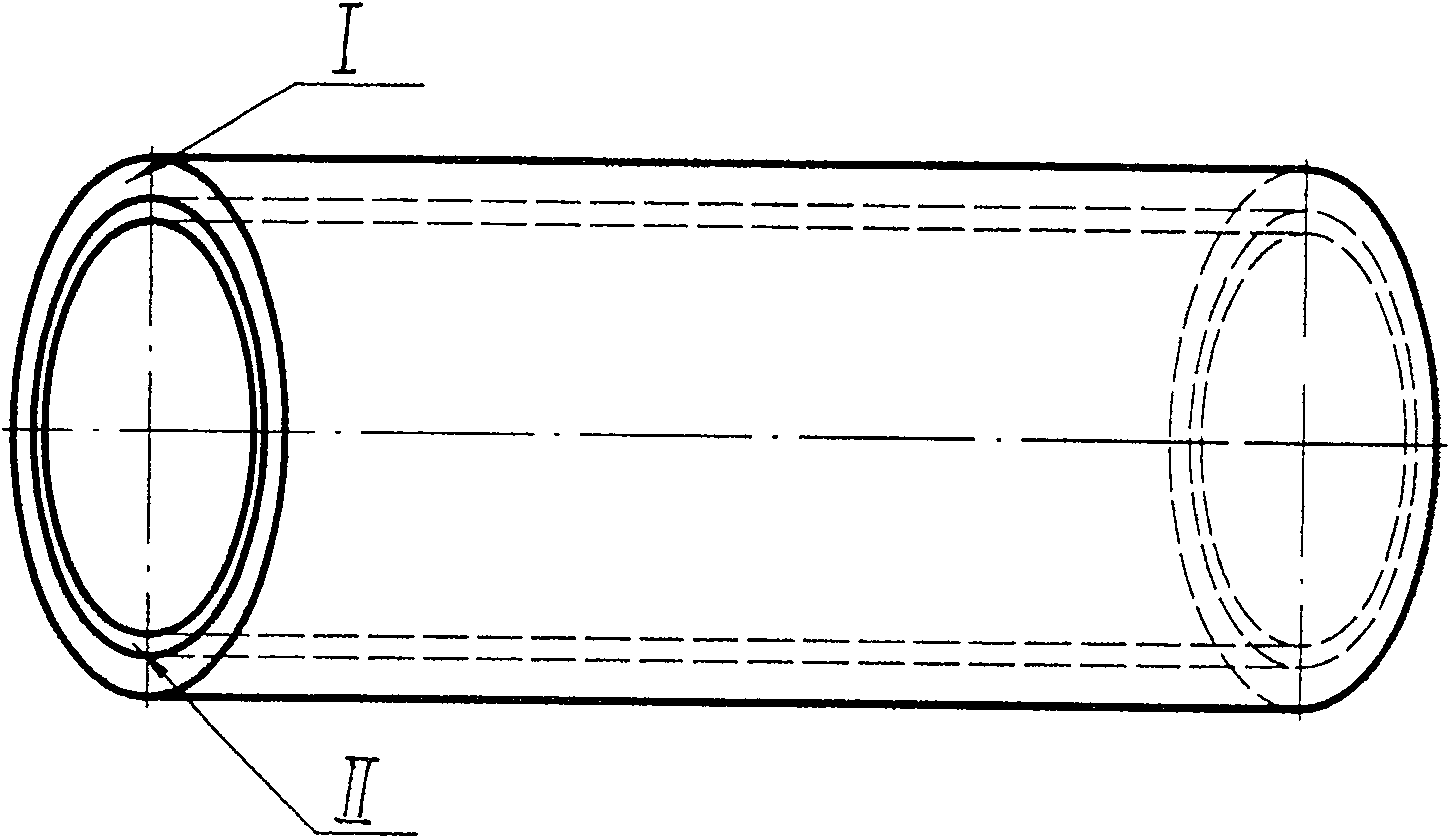

[0041] Select 20# carbon steel seamless pipe as the steel pipe, with a diameter of 60mm, a wall thickness of 4mm, and a length of 8m;

[0042] The raw materials of the inner glass tube are:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com