New electromagnetic anti-wax device

A new type of electromagnetic anti-wax technology, applied in the field of cleaning well devices, can solve the problems of single function, frequent operation, complex structure, etc., and achieve the effect of convenient dismantling, less environmental pollution, and continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

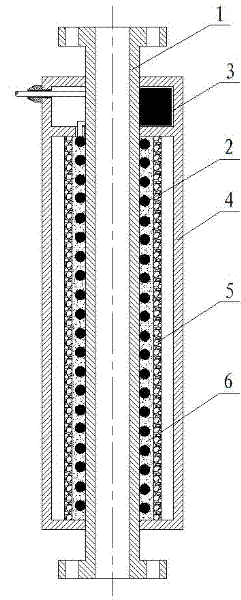

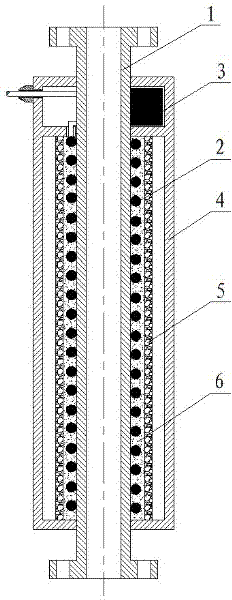

[0012] Depend on figure 1 , figure 2 It can be seen that the novel electromagnetic wax-preventing device is composed of a fuel delivery pipe 1, an electromagnetic coil 2 and a casing 4. The outer wall of the fuel delivery pipe 1 is evenly wound with an electromagnetic coil 2, and the outer side of the electromagnetic coil 2 is provided with a sheath layer 5. The electromagnetic coil 2 and the There is a filler 6 between the sheath layers 5 , one end of the electromagnetic coil 2 is connected to a control circuit board 3 , and the control circuit board 3 and the outer side of the sheath layer 5 are integrally fitted with a casing 4 . The sheath layer 5 is made of heat-resistant insulating material. The filler 6 is cast from insulating material.

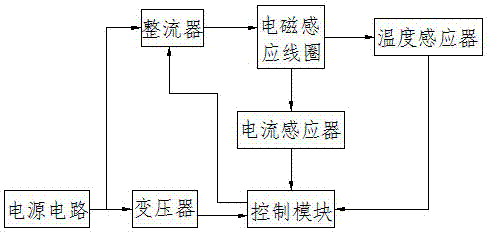

[0013] The control circuit board 3 is to connect one circuit of the power supply circuit to the control module through a transformer, and the other circuit to connect to the electromagnetic induction coil through a rectifier, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com