Method for relieving downward lag of polymer flooding production well sucker rod

A technology for sucker rods and production wells, applied in the field of polymer flooding production well sucker rod down-lag release, polymer flooding well production fluid viscosity reduction technology, can solve the problems of short cycle and high cost, and achieve long cycle and solution Downward hysteresis and low degradation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

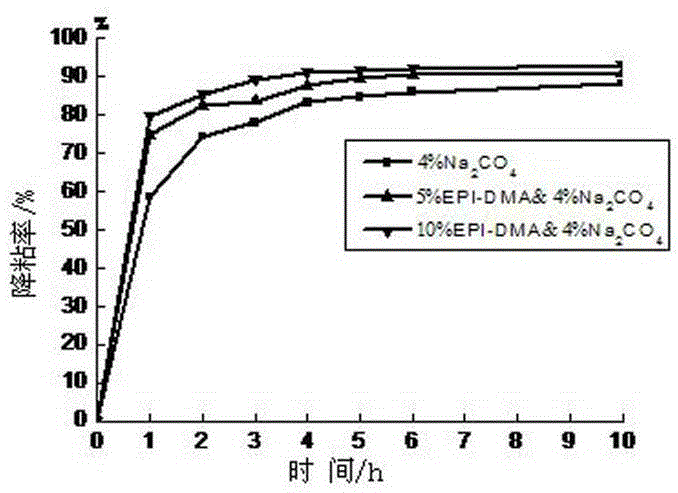

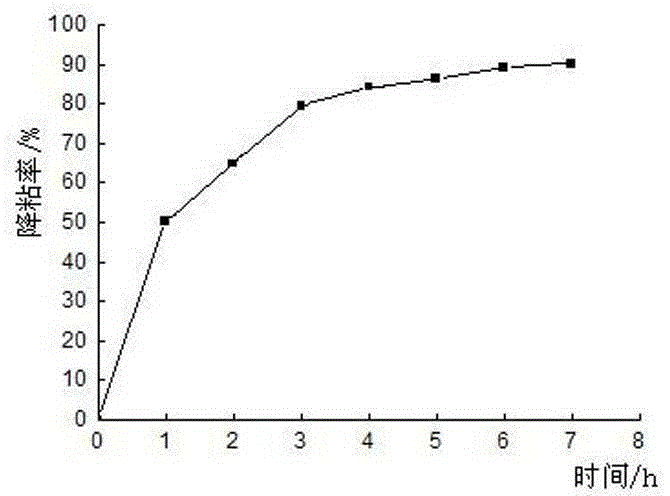

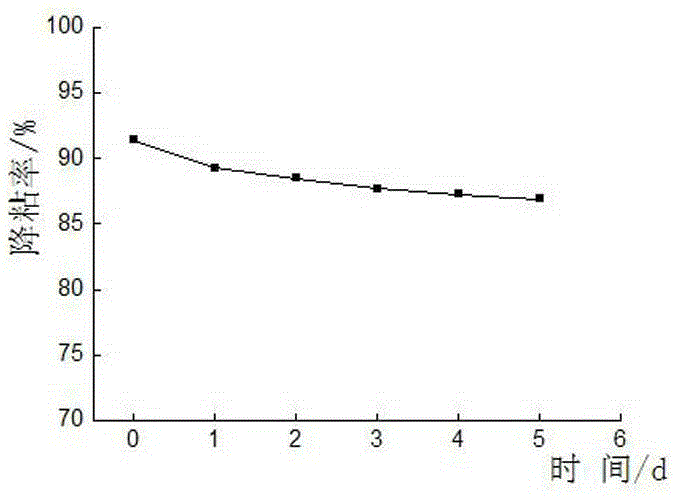

[0022] The method for releasing the downward hysteresis of the sucker rod in the polymer flooding production well: add polyepichlorohydrin amine, sodium carbonate, urotropine, and sulfamic acid to the pumping unit well in normal production by dripping medicine at the wellhead acid, wherein the addition of polyepichlorohydrin amine is 0.5% to 0.8% of the mass of the pumping well production fluid, the addition of sodium carbonate is 0.3% to 0.7% of the mass of the pumping well production fluid, urethane The addition of tropine is 0.1% of the mass of the pumping well production fluid, the addition of sulfamic acid is 2% to 4% of the mass of the pumping well production fluid, polyepichlorohydrin amine and the production fluid Polyacrylamide forms an ultra-low-viscosity association colloid solution; making the production fluid easy to be extracted from the ground.

[0023] Utilize this embodiment to secretly carry out field test of 5 wells in the sixth oil production plant of Daqin...

Embodiment 2

[0028] The method for removing the downward hysteresis of the sucker rod in the polyflooding production well: mix polyepichlorohydrin amine, sodium percarbonate, urotropine, sulfamic acid, and water to form a mixed solution, and after mixing, polyepichlorohydrin amine The mass percentage concentration of sodium percarbonate is 0.5%~0.8%, the mass percentage concentration of sodium percarbonate is 0.3%~0.7%, the mass percentage concentration of urotropine is 0.1%, and the mass percentage concentration of sulfamic acid is 2%~4%. , the amount of solvent water is 94.4~97.2%; for pumping wells with serious hysteresis or stopped pumping, during the well cleaning process, the mixed solution is injected into the bottom of the well through the annular space of the pumping well, and the oxidant at the bottom of the well is first combined with the The effect of polyacrylamide, the polyacrylamide in the formation is oxidized by the oxidant to polyacrylamide or carbon dioxide and water with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com