Anti-corrosion anti-wax anti-fouling coating and preparation method thereof

An anti-fouling coating and anti-wax technology, which can be used in anti-corrosion coatings, coatings, fire-retardant coatings, etc., can solve the problems of low cost and less coating, and achieve the effects of reducing costs, excellent wear resistance and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

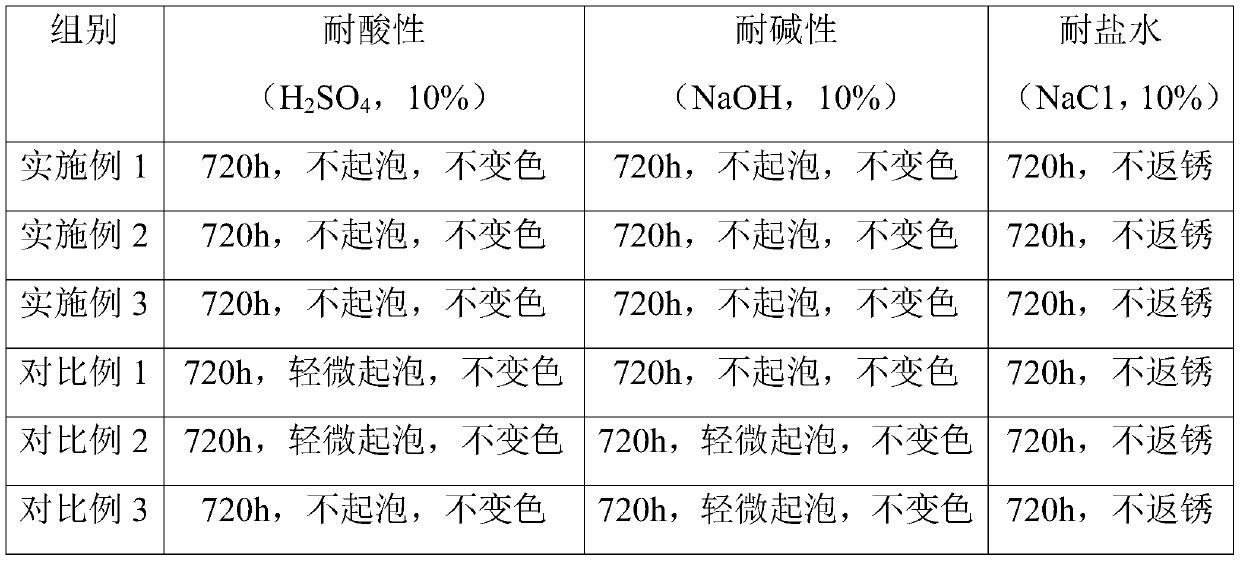

Examples

preparation example Construction

[0026] Wherein, the preparation method of metronidazole-modified graphene oxide composite material comprises the steps: flake graphite and concentrated sulfuric acid are mixed, and after ultrasonic dispersion, stir reaction in ice bath for 20-25min; Then add sodium nitrate to continue reaction 20-25min, then Add potassium permanganate to react for 100-110min; stir the obtained mixture in an oil bath at 39°C and continue to react for 2-3h, then add water, raise the reaction temperature to 95°C, react for 1-2h and then add the mass concentration of 10%-12% hydrogen peroxide solution, reacted for 40-50min, then washed with hydrochloric acid with a molar concentration of 0.35-0.45mol / L, then centrifuged, dried, and ground in sequence to obtain graphene oxide; flake graphite and concentrated sulfuric acid The weight ratio of sodium nitrate, potassium permanganate and hydrogen peroxide solution is 1: (40-50): (1.2-1.5): (4-8): (50-60); the dissolved maleic anhydride Add graphene oxi...

Embodiment 1

[0035] This embodiment provides an anti-corrosion, anti-wax, and anti-fouling coating, which includes an inner layer and an outer layer with a thickness ratio of 1:3.2.

[0036] The raw material components of the inner layer are calculated in parts by weight, including: 10 parts by weight of polytetrafluoroethylene resin, 7 parts by weight of the first filler, 8 parts by weight of boron phenolic resin, 4 parts by weight of methyl methacrylate, and 50 parts by weight of the first solvent Parts, 7 parts by weight of the first curing agent.

[0037] Wherein, the first filler is a mixture of nano-silica, nano-titanium dioxide and polytetrafluoroethylene micropowder with a mass ratio of 1:3:2; the particle diameter of the first filler is 80-100nm; the first solvent is a mass ratio of 1:0.5:1.8 mixture of xylene, butyl acetate and N-methylpyrrolidone; the first curing agent is cashew nut shell liquid modified phenalkamine.

[0038] The raw material components of the outer layer are...

Embodiment 2

[0047] This embodiment provides an anti-corrosion, anti-wax, and anti-fouling coating, which includes an inner layer and an outer layer with a thickness ratio of 1:3.6.

[0048] The raw material components of the inner layer include: 16 parts by weight of polytetrafluoroethylene resin, 5 parts by weight of the first filler, 12 parts by weight of boron phenolic resin, 3 parts by weight of methyl methacrylate, 56 parts by weight of the first solvent part, 4 parts by weight of the first curing agent.

[0049] Wherein, the first filler is a mixture of nano-silica, nano-titanium dioxide and polytetrafluoroethylene micropowder with a mass ratio of 3:5:0.3; the particle size of the first filler is 80-100nm; the first solvent is 1:5 : 4 mixtures of xylene, butyl acetate and N-methylpyrrolidone; the first curing agent is cashew nut shell oil modified phenalkamine.

[0050] The raw material components of the outer layer are calculated in parts by weight, including: 20 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com