A powder metallurgy brass-based etching material with anti-wax function and preparation method thereof

A technology of powder metallurgy and base material, applied in the field of brass-based etching material and its preparation, can solve the problems of difficult implementation, high cost, long production cycle of complex anti-waxing parts, etc., and achieves good anti-waxing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

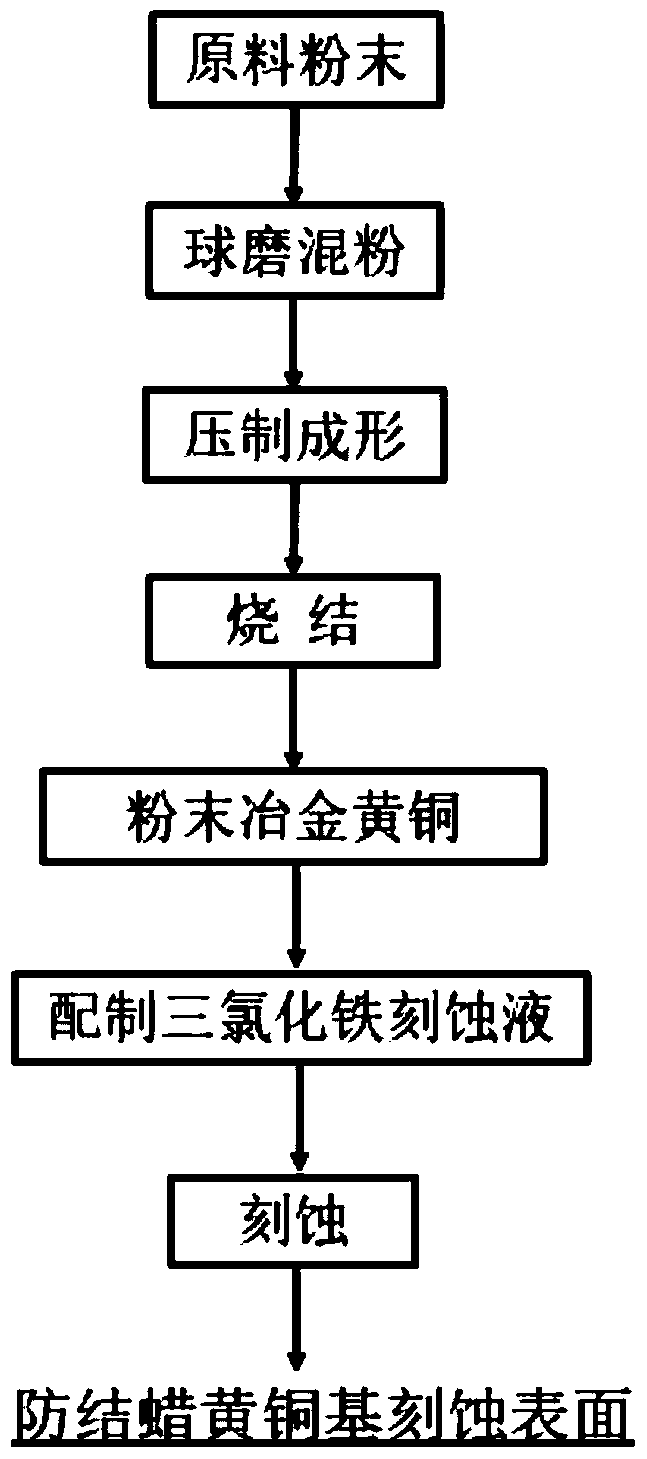

Image

Examples

Embodiment 1

[0014] A powder metallurgy brass-based etching material with anti-wax function and a preparation method thereof, comprising the following steps:

[0015] The first step, the preparation of powder metallurgy brass:

[0016] (1) Ball milling and mixing: mix the pre-alloyed powder with alloy components of Cu80wt%, Zn20wt% and 0.6wt% zinc stearate, and use QM-3A high-energy pendulum ball mill to mix the powder to make the raw material powder components homogeneous and fine particles.

[0017] (2) Compacting compact: adopt SJY50-150T manual isostatic press to compact compact, and the compacting pressure is 800MPa.

[0018] (3) Sintering: The sintering route is as follows: first, heat up to 640°C at a rate of 10°C / min, hold for 40 minutes, then slow down the heating rate to 5°C / min, rise to a sintering temperature of 880°C, and sinter for 60 minutes. The sintering atmosphere is decomposed ammonia. During sintering, in order to reduce the loss of zinc, prevent the compact from bei...

Embodiment 2

[0026] The alloy composition described in this example is 72wt% Cu, 18wt% Zn, 10wt% Ni. All the other preparation processes are the same as in Example 1. The surface was tested for anti-wax deposition, and the amount of wax deposition per unit area was 3.18mg / cm 2 .

Embodiment 3

[0028] In this embodiment, the pressing pressure for preparing powder metallurgy brass is 320 MPa, the sintering temperature is 840° C., and no etching treatment is performed. The surface was tested for anti-wax deposition, and the amount of wax deposition per unit area was 8.31mg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com