Oil-based paraffin remover and inhibitor

A technology of anti-wax agent and anti-wax, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problems such as poor use effect of anti-wax agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

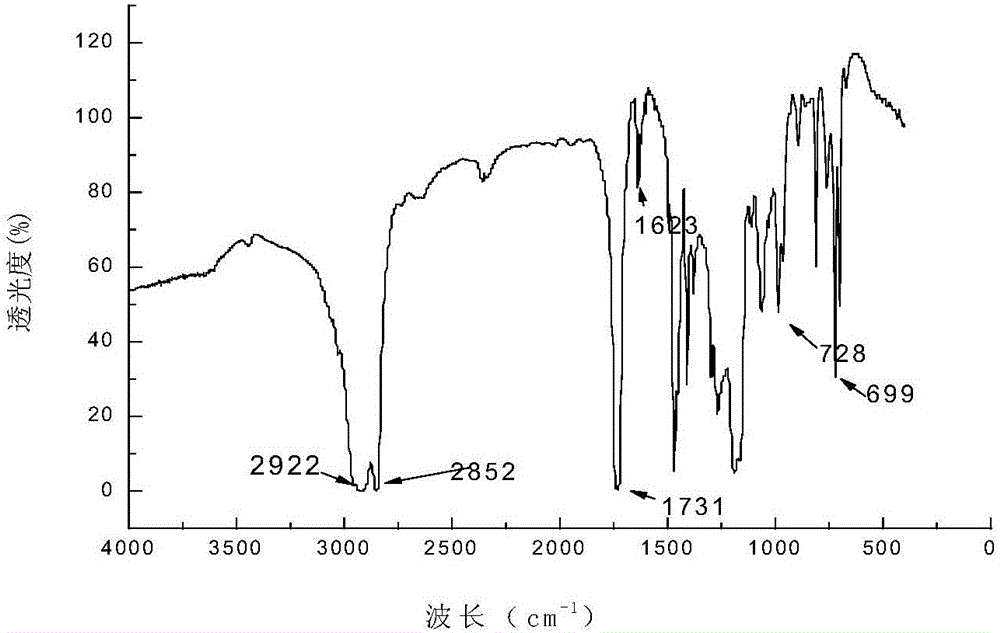

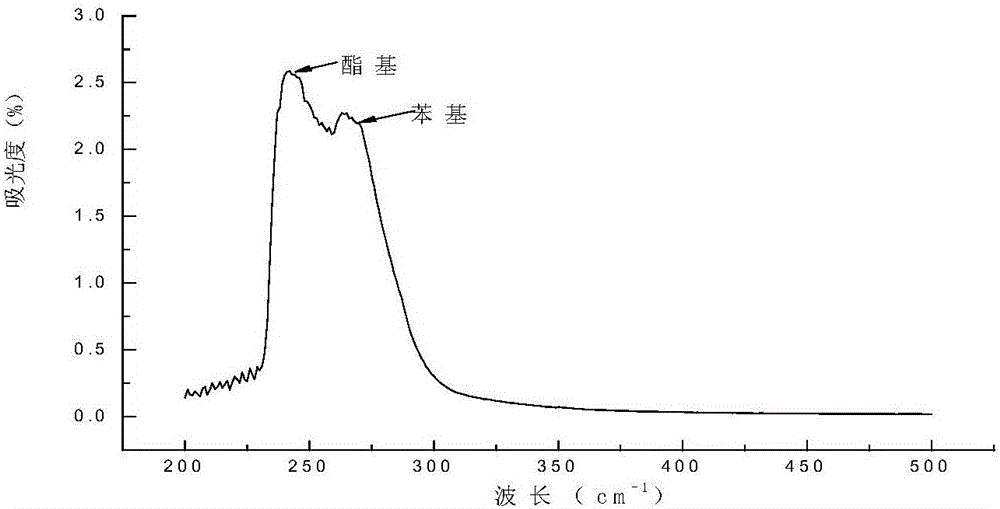

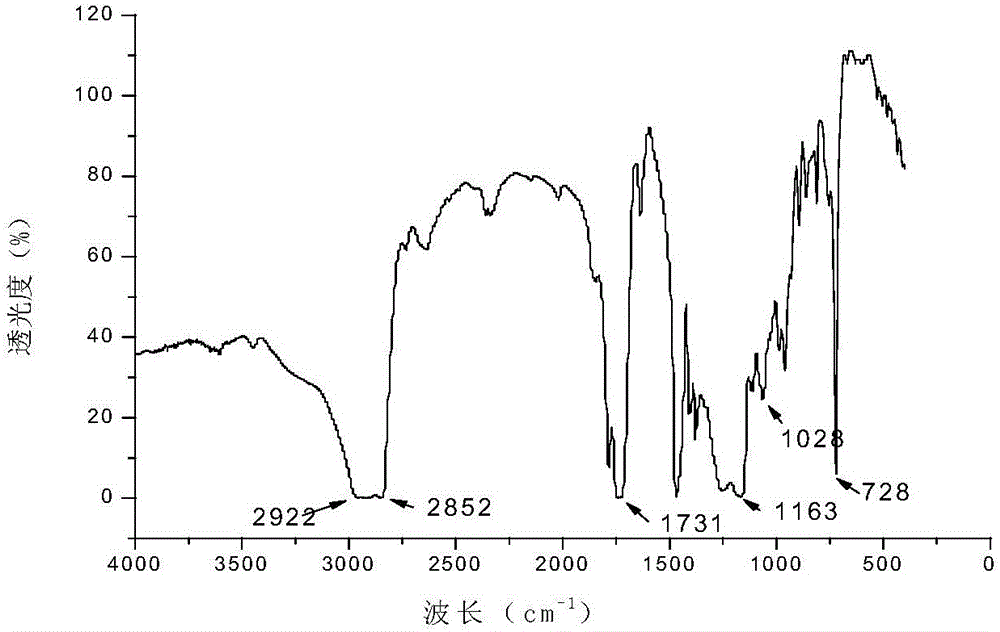

[0014] The oil-based wax remover and anti-wax agent of the present invention is composed of a wax remover and a wax remover, wherein the wax remover is composed of 90-120# petroleum ether, cyclohexane and kerosene, and the weight percentage of various materials is: 90 -120# Petroleum ether 20%, Cyclohexane 30%, Kerosene 50%; Wax inhibitor is composed of wax inhibitor Ⅰ and wax inhibitor Ⅱ, wax inhibitor Ⅰ is composed of octadecyl acrylate and styrene, acrylic acid ten The weight ratio of octadecyl acrylate and styrene is 14:1; wax inhibitor II is composed of octadecyl acrylate and maleic anhydride, and the weight ratio of octadecyl acrylate and maleic anhydride is 28.6:1; oil-based wax remover The weight percent of each component in the composition is: wax remover 95%, wax inhibitor I 2.5%, wax inhibitor II 2.5%.

Embodiment 2

[0016] The oil-based wax remover and anti-wax agent of the present invention is composed of a wax remover and a wax remover, wherein the wax remover is composed of 90-120# petroleum ether, cyclohexane and kerosene, and the weight percentage of various materials is: 90 -120# Petroleum ether 45%, cyclohexane 35%, kerosene 20%; wax inhibitor is composed of wax inhibitor Ⅰ and wax inhibitor Ⅱ, wax inhibitor Ⅰ is composed of octadecyl acrylate and styrene, acrylic acid ten The weight ratio of octadecyl acrylate and styrene is 14:1; wax inhibitor II is composed of octadecyl acrylate and maleic anhydride, and the weight ratio of octadecyl acrylate and maleic anhydride is 28.6:1; oil-based wax remover The weight percent of each component in the composition is: wax remover 80%, wax inhibitor I 10%, wax inhibitor II 10%.

Embodiment 3

[0018] The oil-based wax remover and anti-wax agent of the present invention is composed of a wax remover and a wax remover, wherein the wax remover is composed of 90-120# petroleum ether, cyclohexane and kerosene, and the weight percentage of various materials is: 90 -120# Petroleum ether 20%, Cyclohexane 60%, Kerosene 20%; Wax inhibitor is composed of wax inhibitor Ⅰ and wax inhibitor Ⅱ, wax inhibitor Ⅰ is composed of octadecyl acrylate and styrene, acrylic acid ten The weight ratio of octadecyl acrylate and styrene is 14:1; wax inhibitor II is composed of octadecyl acrylate and maleic anhydride, and the weight ratio of octadecyl acrylate and maleic anhydride is 28.6:1; oil-based wax remover The weight percent of each component in the composition is: 70% of wax remover, 15% of wax inhibitor I, and 15% of wax inhibitor II.

[0019] The specific synthesis method of the anti-wax agent in the above-mentioned three embodiments is as follows:

[0020] First, take the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com