Composite clear antiwax remover

A wax-removing and compound-type technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of wax-dissolving rate, wax-repelling rate limitation, affecting effect, wax easy to crystallize, etc., and achieve wax-dissolving rate High, fast wax melting rate, large wax melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composite wax remover and anti-wax agent in this embodiment includes the following raw materials in parts by mass: 40-80 parts xylene, 10-20 parts ethylene glycol monobutyl ether, 10-20 parts isopropanol, 10-20 parts Polyoxyethylene nonylphenol ether and 15-25 parts weighting agent.

[0031] Among them, the benzene is xylene, the ether is ethylene glycol monobutyl ether, the alcohol is isobutanol, the phenol ether is polyoxyethylene nonylphenol ether, and the weighting agent is ilmenite powder.

[0032] The above-mentioned raw materials were weighed, mixed and stirred to obtain the compound wax remover and anti-wax agent of this embodiment.

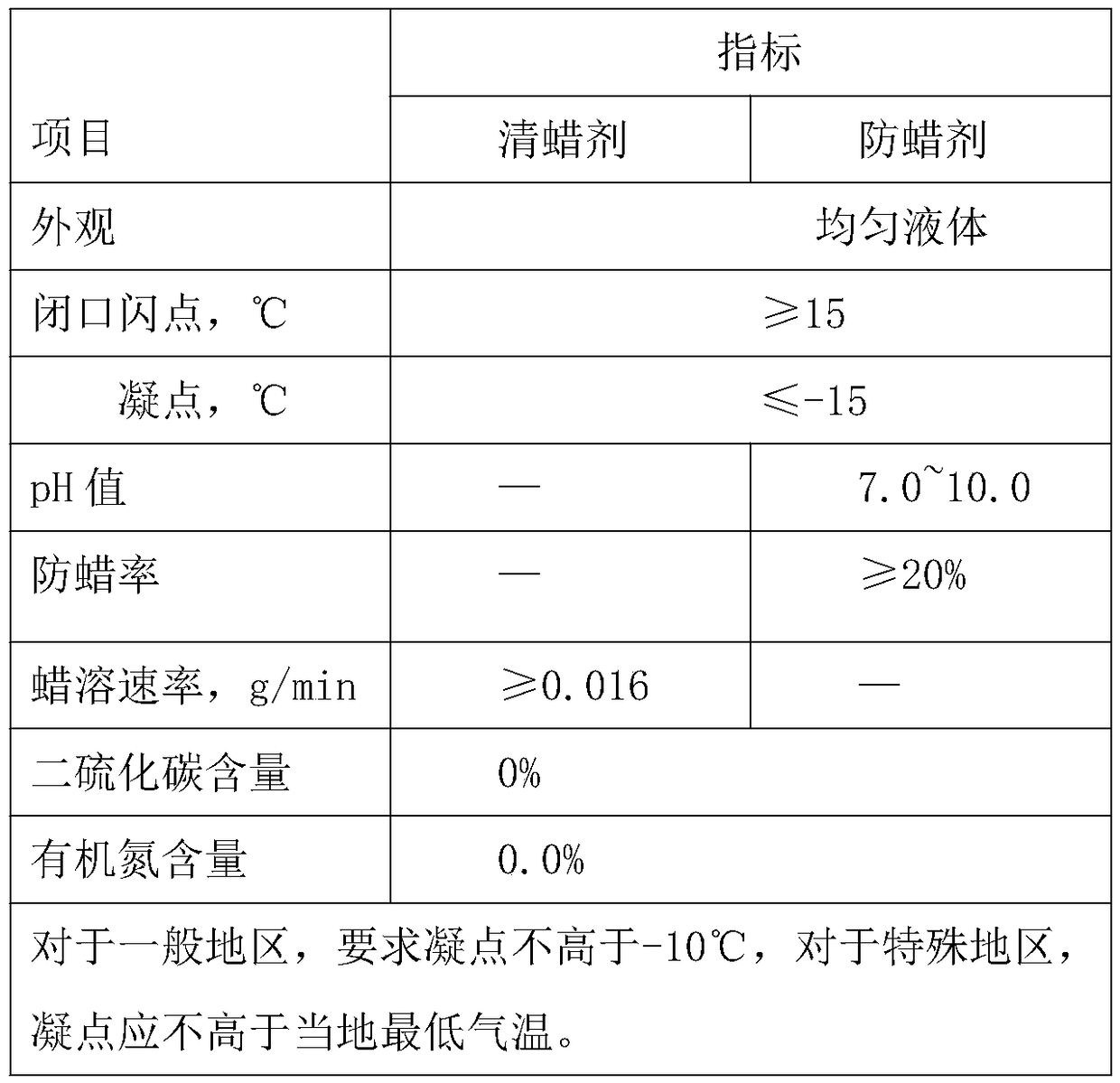

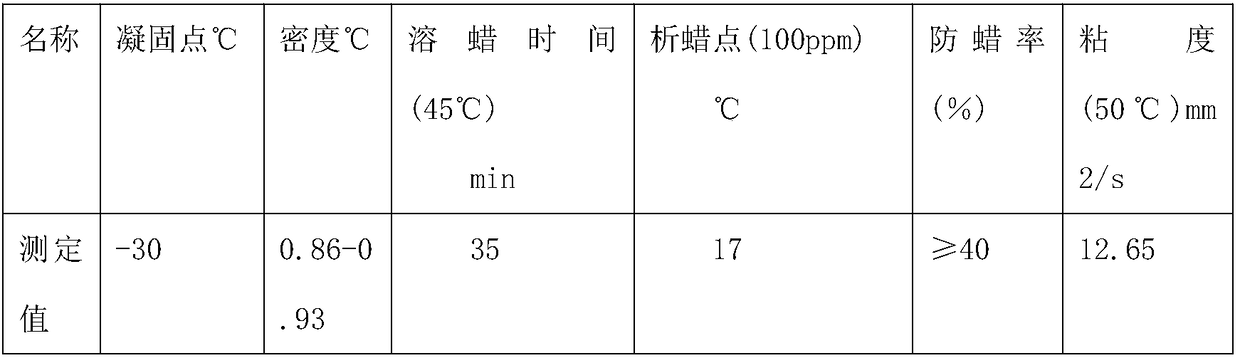

[0033] The composite wax remover and preventive agent prepared in this example has a homogeneous liquid appearance. After measurement, its wax melting rate is 0.002, its wax prevention rate is greater than 40%, and its flash point is 18°C. It not only meets the technical requirements, but is also superior to skills requirement...

Embodiment 2

[0035] In this embodiment, the following raw materials are included in parts by mass: 50 parts of benzene, 14 parts of ether, 14 parts of alcohol, 13 parts of phenol ether and 18 parts of weighting agent.

[0036] Among them, the benzene is xylene, the ether is ethylene glycol monobutyl ether, the alcohol is isopropanol, the phenol ether is polyoxyethylene nonylphenol ether, and the weighting agent is iron ore powder.

[0037] The above-mentioned raw materials were weighed, mixed and stirred to obtain the compound wax remover and anti-wax agent of this embodiment.

[0038] The composite wax remover and preventive agent prepared in this example has a homogeneous liquid appearance. It is measured that its wax melting rate is 0.0035, its wax prevention rate is greater than 40%, and its flash point is 20°C. It not only meets the technical requirements, but is also superior to skills requirement.

Embodiment 3

[0040] In this embodiment, the following raw materials are included in parts by mass: 60 parts of benzene, 15 parts of ether, 15 parts of alcohol, 15 parts of phenol ether and 20 parts of weighting agent.

[0041] Among them, the benzene is xylene, the ether is ethylene glycol monobutyl ether, the alcohol is isopropanol, the phenol ether is polyoxyethylene nonylphenol ether, and the weighting agent is barite powder.

[0042] The above-mentioned raw materials were weighed, mixed and stirred to obtain the compound wax remover and anti-wax agent of this embodiment.

[0043] The composite wax remover and preventive agent prepared in this example has a homogeneous liquid appearance, and its wax melting rate is 0.04, its wax prevention rate is greater than 40%, and its flash point is 30°C. It not only meets the technical requirements, but is also superior to skills requirement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com