Emulsion type asphalt colloid dispersant and preparation method thereof

An emulsion type and dispersant technology, which is applied in building components, building insulation materials, construction, etc., can solve the problems of poor wax removal effect, achieve high wax melting rate, improve stability, and improve dispersion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

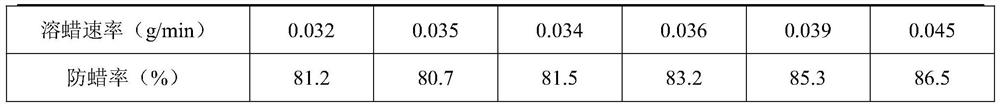

Embodiment 1

[0020] An emulsion-type asphalt colloid dispersant, which consists of 600mL oil phase solvent, 30mL emulsifier, 10mL alkaline conditioner, and 360mL water. Wherein the oil phase solvent is a mixture of petroleum ether, benzene, and cyclohexylamine in a ratio of 7:7:6, the emulsifier is fatty alcohol polyoxyethylene ether, and the alkaline regulator is sodium hydroxide.

[0021] The preparation method is as follows: adding an emulsifier and an alkaline regulator into water for stirring and dissolving to obtain a mixed solution; adding an oil phase solvent to the mixed solution and emulsifying at a high speed to obtain the emulsion-type asphalt colloidal dispersant .

Embodiment 2

[0023] An emulsion-type asphalt colloid dispersant, which consists of 800mL oil phase solvent, 60mL emulsifier, 15mL alkaline regulator and 125mL water. Wherein the oil phase solvent is a mixture of petroleum ether, toluene, and cyclohexylamine at 7:7:6, the emulsifier is fatty alcohol polyoxyethylene ether, and the alkaline regulator is sodium oxalate.

[0024] The preparation method is as follows: adding an emulsifier and an alkaline regulator into water for stirring and dissolving to obtain a mixed solution; adding an oil phase solvent to the mixed solution and emulsifying at a high speed to obtain the emulsion-type asphalt colloidal dispersant .

Embodiment 3

[0026] An emulsion-type asphalt colloid dispersant, which consists of 700mL oil phase solvent, 50mL emulsifier, 10mL alkaline regulator, and 240mL water. Wherein the oil phase solvent is a mixture of petroleum ether, xylene, and cyclohexylamine at 7:7:6, the emulsifier is alkylphenol polyoxyethylene ether, and the alkaline regulator is sodium citrate.

[0027] The preparation method is as follows: adding an emulsifier and an alkaline regulator into water for stirring and dissolving to obtain a mixed solution; adding an oil phase solvent to the mixed solution and emulsifying at a high speed to obtain the emulsion-type asphalt colloidal dispersant .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com