Oil-base paraffin remover for oil wells

A technology of wax remover and oil-based remover, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as environmental protection, unsafety, and low flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

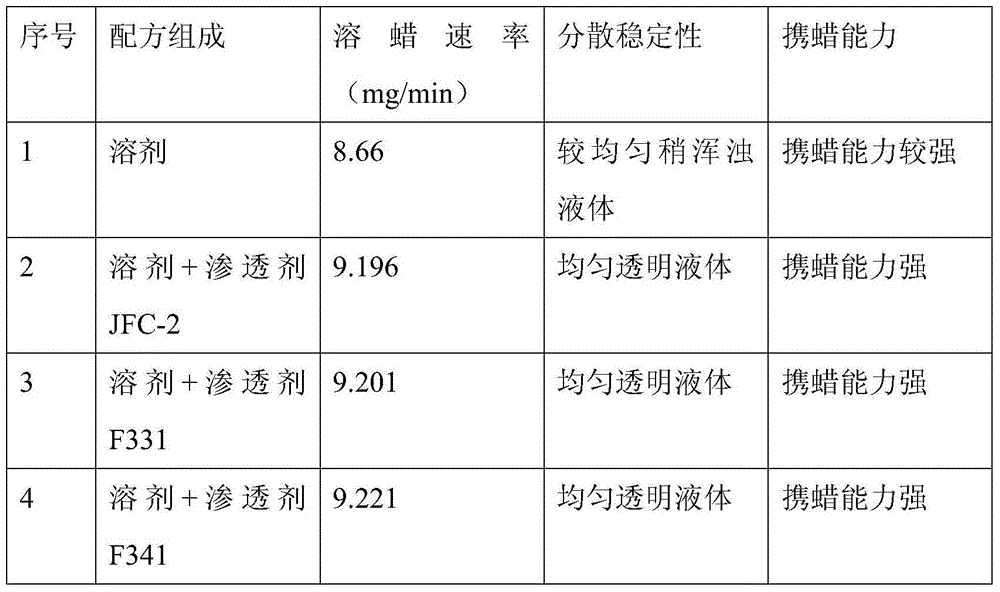

Examples

Embodiment 1

[0024] By volume, mix 25% of xylene, 10% of trimethylbenzene, 15% of octane, 40% of white mineral oil, 10.6% of penetrant F33, 7.05% of n-octanol and 2.35% of n-pentanol, and the obtained liquid is The properties of wax remover 1 of the present invention are shown in Table 2.

Embodiment 2

[0026] By volume, mix 29% of xylene, 12% of trimethylbenzene, 14% of octane, 41% of white mineral oil, 10.67% of penetrant F34, 1.1% of n-octanol and 0.055% of n-pentanol, and the obtained liquid is Wax remover 2 of the present invention.

[0027] Table 2 wax remover performance

[0028] Exterior

[0029] It can be seen from Table 2 that the paraffin remover has a wax melting rate >20mg / min, an open flash point >40°C, a freezing point <-60°C, and does not contain sulfur or chlorine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open flash point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com