Steam self-circulation device of wax removing vehicle

A wax cleaning vehicle and self-circulation technology, used in cleaning appliances, isolation devices, wellbore/well components, etc., can solve problems such as low efficiency, wasted steam, and large energy waste, reduce energy consumption, and prevent excessive temperature. , to ensure the effect of wax removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

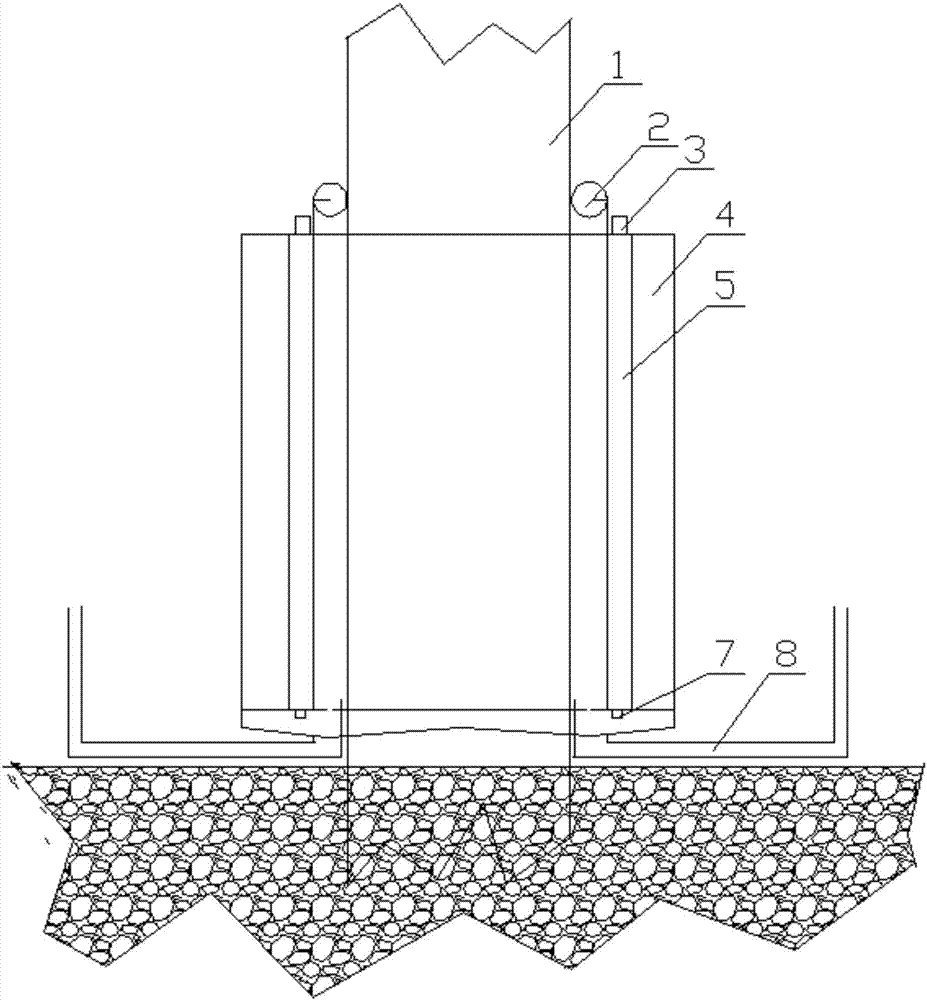

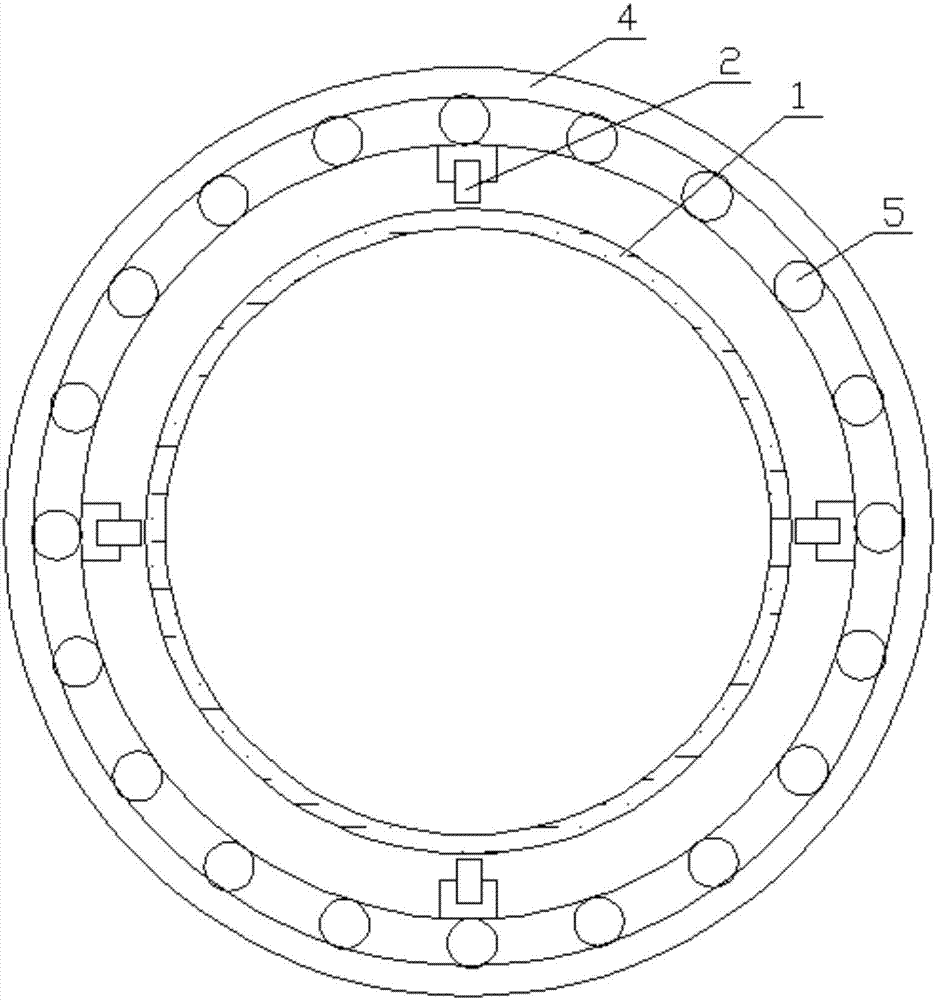

[0020] Such as figure 1 with figure 2 As shown, the steam self-circulation equipment of the wax removal vehicle includes an oil extraction pipe 1, and also includes a cylindrical shell, which is a hollow structure, and the oil extraction pipe 1 is arranged in the middle of the shell; The axis of the steam inlet pipe 5 is parallel to the axis of the shell; the top of the steam inlet pipe 5 is provided with a steam inlet 3, and the outer surface of the steam inlet pipe 5 is evenly distributed on a high line close to the oil extraction pipe 1. A plurality of air outlets are provided, and the bottom of the steam inlet pipe 5 is provided with a pipeline liquid recovery hole 7; a flow guide device is provided at the bottom of the shell, and the flow guide device is a hollow cylinder without a cover, and the upper side of the flow guide device is connected to the The outer surface of the casing is connected, and the bottom of the flow guiding device is a right conical structure wit...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is that the steam inlet pipe 5 is a spiral pipe, and the spiral pipe is bonded to the outer surface of the inner side of the shell from top to bottom, and the outer surface of the spiral pipe close to the oil extraction pipe 1 is uniformly arranged with Multiple vents. The upper end of the spiral pipe is provided with a steam inlet 3, and the lower end of the spiral pipe is connected with a pipeline liquid recovery hole 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com