Permanent magnet ultrasonic paraffin control device

A technology of wax preventer and ultrasonic, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of restricting the normal production of oil wells, limited effect of wax prevention and wax removal, complicated process, etc., and achieves enhanced wax prevention Good effect, good anti-wax effect, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

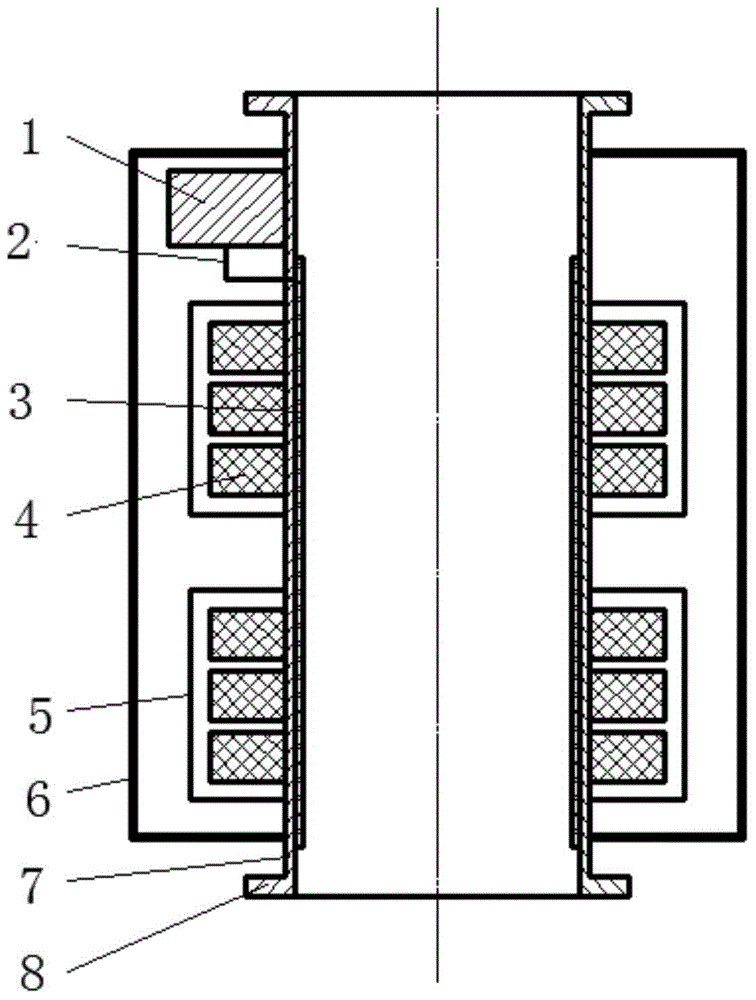

[0012] Such as figure 1 As shown, a permanent magnet ultrasonic wax preventer at least includes: an ultrasonic generator 1, a cable 2, an ultrasonic transducer 3, a permanent magnet 4, a magnet cover 5, a protective box 6, an inner tube and a flange; Both ends of the inner tube are provided with a flange, and an ultrasonic transducer is installed on the inner wall of the inner tube, and the ultrasonic transducer is electrically connected to the ultrasonic generator on the upper end of the outer wall of the inner tube through a cable; The permanent magnet is located at the lower end of the ultrasonic generator, and the permanent magnet is provided with a magnet cover; the inner tube between the two flanges is covered with a protective box, and the ultrasonic transducer, permanent magnet and magnet cover are all in the protective box; The N poles and S poles of the above permanent magnet 4 are alternately arranged in combination, so that it forms a helical alternating strong mag...

Embodiment 2

[0015] On the basis of Embodiment 1, the ultrasonic transducer 3 is in the shape of a circular tube and is sleeved in the inner tube 7 . The permanent magnet 4 is an arc-shaped body in which a plurality of N poles and S poles are arranged alternately up and down in combination. There are two permanent magnets 4, so that the magnetic field forming the helical alternating strong magnetic field is stronger and the magnetic path is longer. The area where the magnetic field and ultrasonic coupling superimpose is larger, and there are both vertical field areas and parallel field areas inside, which enhances the anti-wax effect of the magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com