Novel sucker rod centralizer

A technology for sucker rods and centralizers, which is applied to drill pipes, drilling equipment, and earthwork drilling and production, and can solve problems such as the limitation of the effective wear-resistant area of the centralizer, the limitation of the effective area of the diversion of the centralizer, and poor centralization effect. Achieve good wax resistance effect, good righting effect, and large wear-resistant area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

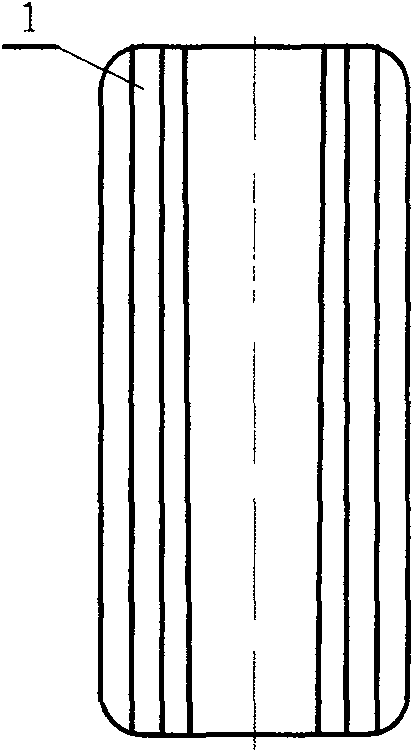

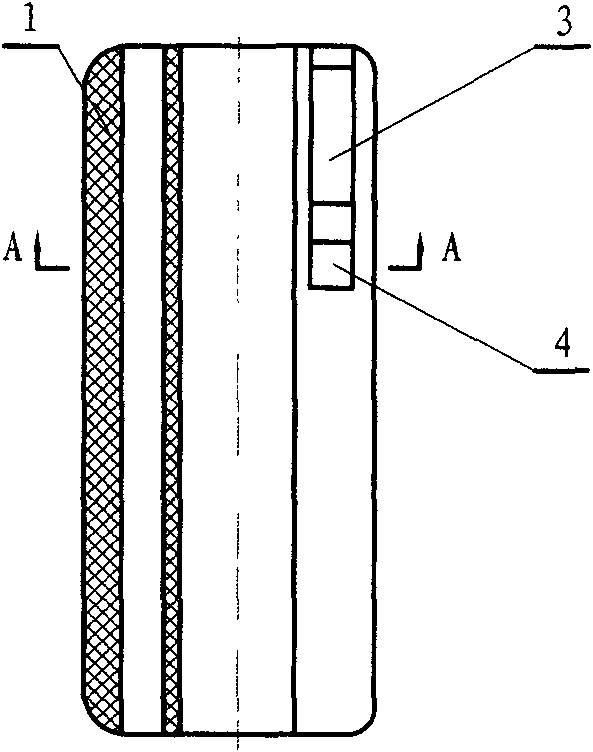

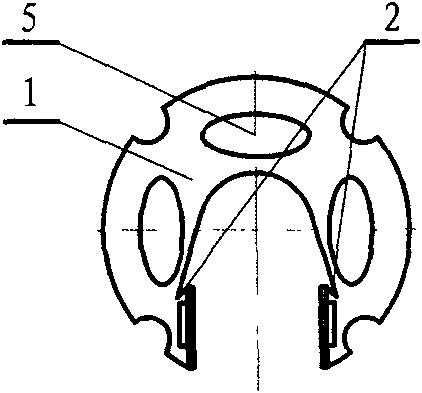

[0016] From as attached figure 1 , 2 , 3, 4 shown in the opening of the main body 1 snap into the sucker rod, and then insert the sucker rod as attached Figure 5 , 6 The wedging body 6 shown in , 7 and 8 is inserted from the top of the main body 1, and the wedging key 7 on the wedging body 6 is inserted into the keyway 2 of the main body 1, so that the main body 1 and the wedging body 6 form a Complete centralizer, the sucker rod is tightly stuck in the centralizer. In the above process, since the joints of the main body 1 and the wedging body 6 are all designed to be large at the top and small at the bottom (in the state shown in the drawings), the bonding of the contact surface after the wedging body 6 is wedged into the main body 1 is ensured. The introduction slope 3 provided at the opening of the main body 1 ensures the smooth introduction of the positioning block 8 on the wedge body 6 into the positioning groove 4 . The cooperation of the positioning block 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com